Production Process Flow |

|

►▼ |

►▼ |

►▼ |

►▼ |

►▼ |

|

►▼ |

►▼ |

►▼ |

►▼ |

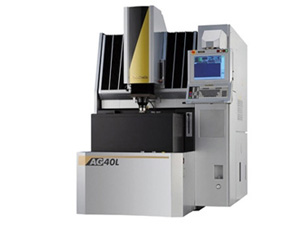

In-house mold manufacturing equipmentPrototypes can be produced with a short lead time. |

|

AMADA MACHINE TOOLS |

Sodick |

Mori Seiki |

|

Sodick |

Sodick |