The Incredible SIRIUS Processing

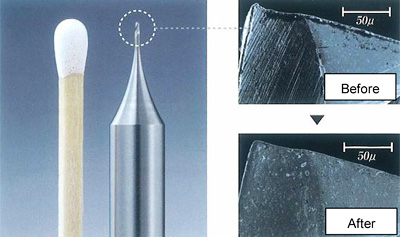

-Removing unnecessary burrs without damaging the surface!-

A new generation of surface finishing

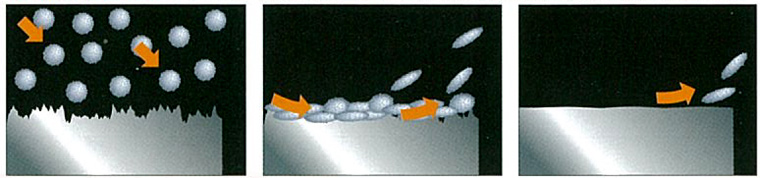

It’s a new processing technology which can process the workpiece without damaging it, using our unique “Sirius media”.

It’s mainly used for finishing of molds or tools.

Features |

● The machine can be automated according to the workpiece or the aim of processing. A robot can be mounted.

● There is a lot of flexibility in processing owing to the system using nozzles.The dimension and the weight of a workpiece is

not limited. The number of nozzles can be increased.

● The media can be used continuously. The way of automated supply of media is simply adding new media.

● The consumption amount of media is only 30 grams per hour in standard processing conditions. It drastically reduces the running cost.

● There is no need for recycling the media nor regulating the moisture retention.

● Our own digitally-controlled blasting system realizes stable processing.

● The machine uses the clean dry system that produces little dust. In addition, the dust is caught by a dust collector.

The Sirius processing technology is suitable for

|

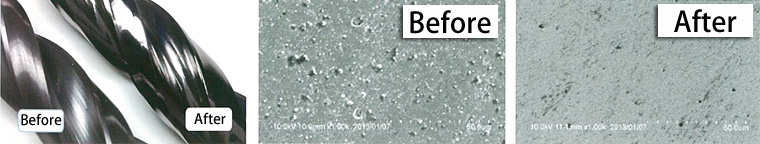

Droplet removal of TiAIN coating carbide drill (Φ10mm) |

Image SEM |

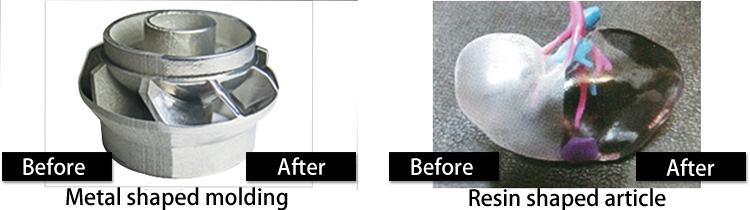

Lamination step of the 3D printer shaped product Removal and visalization |

Mold polishing“ Polishing ” is the final process of making a mold. Sirius processing can reduce cost by cutting the polishing time down, while improving quality by avoiding unevenness of finish. Sirius solves problems of manual polishing. |

|

Sirius user’s comments |

From a user who has been manually polished cold forging molds" Sirius reduces the operation time drastically compared to manual polishing. " |

From a user who has been manually polished rubber molds by a rubstone" Sirius doesn’t damage molds. It never polishes too much. " |

From a user who has been manually polished press molds" There is neither personal finishing difference nor partial unevenness. " |

From a user who has been polished forming racks by other method"Sirius can polish a groove where is difficult to reach,or a bended surface where is difficult to put a tool on." |

From a user who has been finished plastic molds by blasting" The quality can be improved by using Sirius after blasting. " |

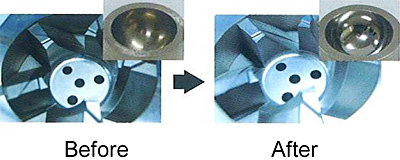

To remove microscopic burrs of tools

|

|

Sirius user’s comments |

From a user who considered a way to remove burrs of stainless-steel products." I never thought that could be done in an incredibly short time. " |

From a user who improved the quality of the hollow punch by removing burrs." We realized a cost saving because the lifetime of tool was increased. " |

From a user who has been manually removed burrs of the ultra-hard tool." No need for a special technique. Anyone can do it. " |