Other products

Other products

Tsukatani(Thailand)Co.,Ltd. has a special rule and punch also.

Please click the panels.

| |

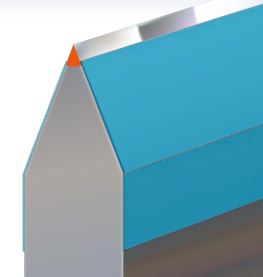

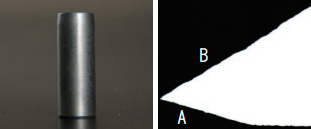

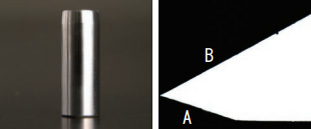

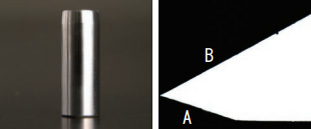

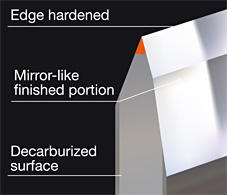

Mirror-like finishing TUBE PUNCH『G-SHOT』

|

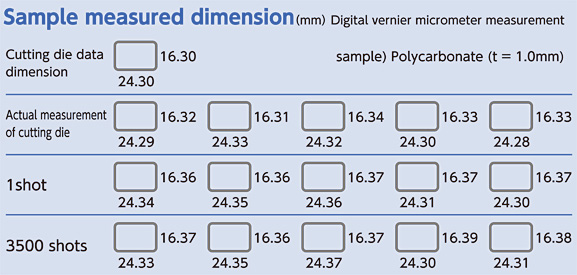

Improve the precision highly by special process!

Progress the cutting power and section remarkably!

|

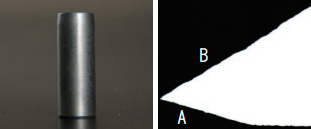

8.0φ Bevel section

| Tube Punch |

G-SHOT |

|

|

| Surface roughness(µm) |

Facet bevelA |

Facet bevelB |

| Ra |

0.238 |

1.798 |

| Ry |

1.730 |

10.210 |

| Rz |

0.891 |

6.833 |

|

| Surface roughness(µm) |

Facet bevelA |

Facet bevelB |

| Ra |

0.125 |

0.100 |

| Ry |

0.740 |

0.640 |

| Rz |

0.568 |

0.582 |

|

|

Solution to cut difficult form by steel cutting rules, joints and dusts!

|

|

|

|

| Recoil type |

Side Type |

Cannon type |

Joint type |

| Recoil type |

Side/Cannon/Joint type |

| Hardness |

HRC52~53/58~59 |

Hardness |

HRC52~53/58~59 |

| Height |

3.0mm |

Height |

2.0~4.5mm |

| Thickness |

0.7mm |

Thickness |

0.7~1.8mm |

| Edge angle |

30° / 40° |

Edge angle |

30° / 40° / 50° |

| Base through hole |

φ0.8 or more |

Base process |

Slit process available |

| Tapped hole |

M3 or more |

Min. line gap |

1.0mm |

| Min. line gap |

1.4mm |

Min. radius |

Side/Cannon:0.5R |

| Min. radius |

0.1R |

Joint:0.1R |

|

Solution of paste and bonding agent stuck to edge problem during cutting double sided tape

Feature of coated rule

♦ Paste sticking to rule and products is reduced and cleaning times of cutting die can be reduced.

Points to notice when choosing coated rule

♦ Product cutting finish / Non-adhesive characteristic / Grasp of shots qty control

♦ Grasp of cleaning method

|

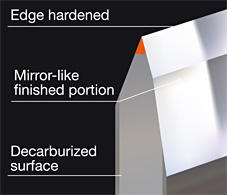

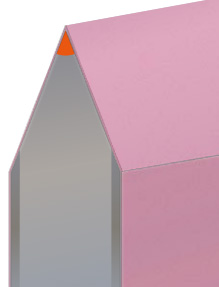

Process the whole uniformly and evenly to be accurate condition

By coating surface with hardness Hv900 - 1,000, abrasion proof up !

"Abrasion of rule edge" by metallic pigment

|

|

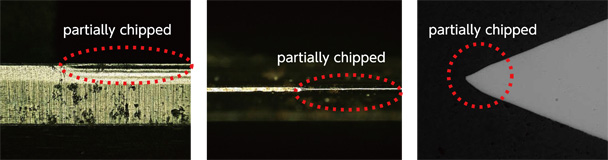

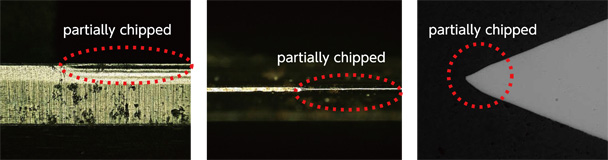

Chipped by metal(Ti), partial cutting unevenness occurs.

|

Feature of H-Cr coated rule

♦ When processing printed products, there are cases that rule edge is partially chipped and cutting unevenness occurs. Such a phenomenon can be seen at white color printing parts. It is caused by the pigment (mainly Titanium dioxide) to emphasize white color. H-Cr coating makes whole of a steel cutting rule coated with Hv900 - 1,000 hardness, which prevents damage by Titanium dioxide and makes it possible to cut the whole uniformly and evenly to be accurate condition.

♦ Useful for durability required cutting process.

♦ Suitable for mold goods' process like resin tray

|

|

| |

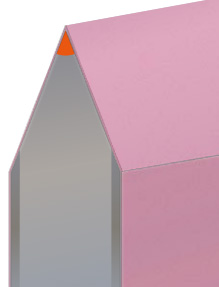

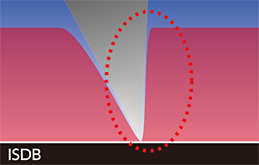

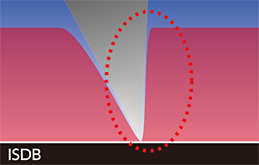

Irregular Side Double Bevel

|

Less lean of cutting edge at bent R than center bevel rule and easy levelling.

Whitening, crinkled of narrow part and crimp can be reduced even for thin materials.

Feature of ISDB

♦ In case of cutting thick materials, cutting edge is tend to lean outwards and it often cuts bigger than dimension and tends to be tapered at cross section. But by this rule, it makes inner side of products acute angle and outer side obtuse angle, which makes leaning back the cutting edge inward. So straight and clean cross section is possible and dimensionl change is not frequent and precise cutting is possible.

|

|

| |

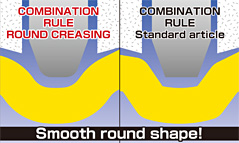

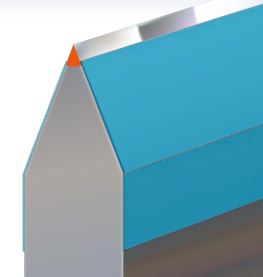

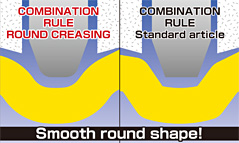

Combination Rule with Round Creasing

|

New combination rule that prevents printed surface from crack

|

FEATURE OF

COMBINATION RULE WITH ROUND CREASING

♦ Creasing of general combination cutting /creasing is flat. So printed side is often damaged by edge, which brings crack while making a box. On the other hand, creasing of combination rule with round creasing is formed R shape which prevents damage on printed side and die/cutting process can be done keeping the printed side fine.

♦ Requirement of counter plate and face cut tape is the same as general combination cutting/creasing.

|

Other products

Other products