Curved Surface and Specular Inspection Device HS-IR 100

~Speedier and more accurate~

Visual Inspections that are superior to the naked eye.

An articulated device capable of positioning the camera head perfectly to inspect curved surfaces, optics capable of resolving even the most minute scratches on a polished surface, and image processing software that finds every defect.

Suitable for finding all kinds of surface defects, including scratches, pinholes, bruises, burrs, and dimples. Suitable for parts of all sizes and shapes, from cellphone cases to car doors.

►►► Inspection Range

0.01m~1.5m

►►► Performance

| Type of defect | Performance | Type of defect | Performance |

| Scratch | As small as 0.1mm | Sagging | As small as 0.1mm |

| Burr | As small as Φ0.5mm~ | Soiling | As small as Φ0.5mm~ |

| Dimple | As small as Φ1.0mm~ | Wrinkle | As small as 0.1mm |

| Bruise | As small as Φ0.5mm~ | - | - |

※for a 0.3-megapixel camera in a 30×40 mm range field of view

►►► Typical Defects

Typical scratch 1Scratch on paint |

Painted surface |

Camera image |

Defect detection image |

Typical scratch 2Scrach on glass |

Glass surface |

Camera image |

Defect detection image |

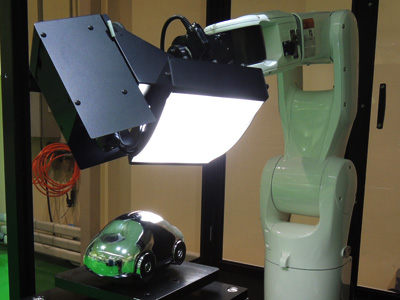

►►► How it works

|

|

|

►►► Movie

►►► Subjects for inspection

・Electric appliances, automotive parts, and oter parts with a plated or painted finish suface

・Cellphone cases and othe plastic parts