Aluminium Die Casting / Machining

Aluminium Die Casting

- High pressure die casting: We have die casting machine with superior range of capabilities from 135 ton to 500 ton, and we are capable to produce luxury parts, efficiently in complex shapes, light weight or high strength. It is suitable for mass production.

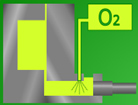

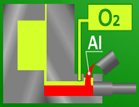

- Pore Free Die casting: This method can control gas in the cavity replaced by oxygen can make no blowholes material by chemical reaction with aluminium.

Manufacturing Process

1. MeltingMelting Furnace |

|

|

|

|

|

|

3. Shot Blasting

|

|

|

| ♦ Machine List ♦ | ||||

|---|---|---|---|---|

| Description | Q’ty | Description | Q’ty | |

| Die Casting Machine 135 Ton | 2 | Melting Center Furnace 1 Ton | 2 | |

| Die Casting Machine 350 Ton | 5 | Melting Center Furnace 2 Ton | 2 | |

| Die Casting Machine 500 Ton | 1 | Shot Blast Machine | 3 | |

| Press Machine | 6 | |||

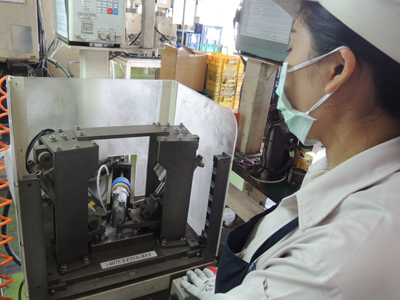

Machining

- We have over 30 machine units with wide variety of machining capabilities that can control complex shapes and tolerance according to our customer’s requirements.

| ♦ Machine List ♦ | ||||

|---|---|---|---|---|

| Description | Q’ty | Description | Q’ty | |

| Machining Center (#30) | 18 | Water Leak Tester | 10 | |

| Machining Center (#40) | 3 | Pipe Pressing Machine | 6 | |

| CNC Lather Machine | 15 | Washing Machine | 18 | |

| Air Leak Tester | 6 | Other | 28 | |

Mold / Tooling / DieTechnology

- We have the capabilities to develop and produce Mold, Tooling and Jig fixture in-house to optimize the engineering technology for die casting business. We meet customer’s specifications, and perform various inspections during the production process.

| ♦ Machine List ♦ | ||||

|---|---|---|---|---|

| Description | Q’ty | Description | Q’ty | |

| Drill Machine | 1 | Grinding Machine | 1 | |

| Milling Machine | 1 | Machining Center | 1 | |

| Lathe Machine | 1 | CNC Turning Center | 1 | |

| Welding Machine | 1 | EDM | 1 | |

| Laser Welding | 1 | |||

2. Casting

2. Casting