Cogeneration

Road to Innovative Field with Global Power.

From the past decade, Thai Shinryo has expanded its interest in Co-Generation and District Cooling System (DCS) technologies to become a leading Engineering, Procurement and Construction (EPC) Contractor in Thailand. Those efforts have been in line with our corporate policy in terms of environmentally friendly, contributions to society, urban life and all mankind.

In September 2006, our first 55 MW Co-generation project, "DISTRICT COOLING SYSTEM & POWER PLANT PROJECT at SUVARNABHUMI INTERNATIONAL AIRPORT", was complete and commercially operation for supplying Power Energy, Steam and Chilled Water to Suvarnabhumi International Airport.

Today, many SPP Projects in Thailand have been developing very fast. Meanwhile Thai Shinryo has progressively developed our team to cope with larger scale and variety of Power Generation System. We have completed more projects and achieved owner objectives as reducing air pollution, saving energy, countering global warming and efficient using of new energy resources. All of those projects were designed to provide stable and cost-effective energy supplies whilst respecting environmental friendly by the process.

Combined Cycle Power Plant and Cogeneration

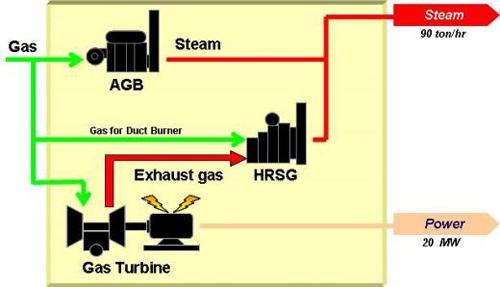

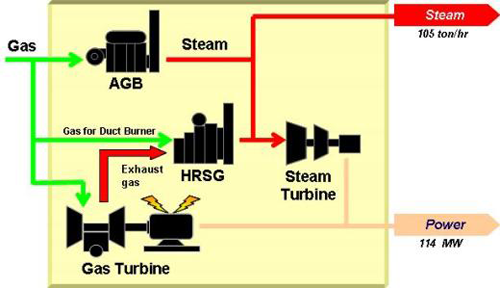

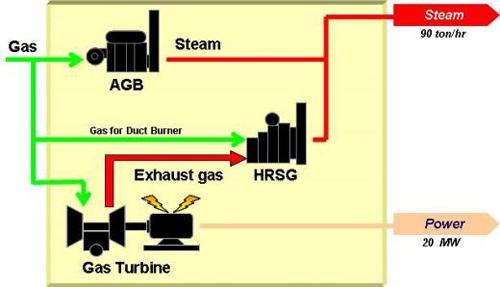

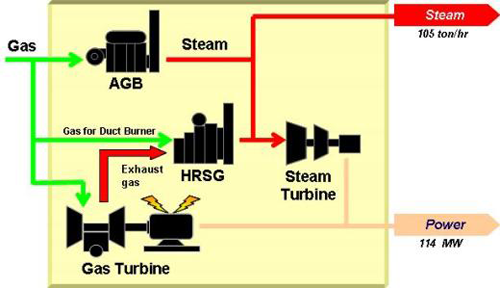

Combined Cycle Cogeneration Power plant uses natural gas fuel to generate electricity by Gas Turbine Generator while it minimizes thermal energy discharged to environment by heat recovery process and steam turbine process.

Combined cycle process combines gas turbine and steam turbine thermodynamic cycles by using Heat Recovery Steam Generator (HRSG) to capture the exhaust heat energy discharged from gas turbine. Firstly, the fuel is ignited at Gas Turbine to produce mechanical energy and to drive an electric generator. Electric generator then generates electric power. High temperature waste heat from the ignition will then be used to heat up water by HRSG and transform it into high pressure steam. High pressure steam will be fed to a steam turbine for more electricity generation.

For a Combined Cycle Co-generation Power Plant, some part of lower pressure steam is extracted at steam turbine to used as process steam. Such process steam can be supplied directly to industrial users or fed to a steam absorption chiller to produce chilled water for air conditioning or process cooling applications.

Experienced Projects

►►► Bangpa-in Cogeneration (BIC 1)

This Project is Cogeneration Power Plant that located at Ayuddhaya Province.

Project Description :The Plant comprises 2 Gas Turbine Generator (GTG), 2 Heat Recovery Steam Generator (HRSG), 1 Steam Turbine Generator and 1 Auxiliary Boiler.

Configuration

|

Gas Turbine Generator

|

LM 6000PD, 47.5 MW x 2 units

|

|

Heat Recovery Stream Generator

|

43 ton/hour x 2 units, 16 ton/hour x 2 units

|

|

Steam Turbine Generator

|

23 MW x 1 unit

|

|

Auxiliary Boiler

|

20 ton/hour x 1 unit

|

Project Owner : Bangpa-in Cogeneration Limited (BIC)

Construction Period : March 2011 - June 2013

Commercial Operation Date : June 2013

|

►►► Bangchak Utility Project

This Project is the Combined Heat and Power (CHP) Plant that located within the Bangchak refinery complex in Bangkok.

Project Description : The CHP Plant consist of 2 Gas Turbine Generator (GTG), 2 Heat Recovery Steam Generator (HRSG) with supplementary firing and 1 Auxiliary Boiler for serving as back up steam source.

Configuration

|

Gas Turbine Generator

|

Titan 130, 12 MW x 2 units

|

|

Heat Recovery Stream Generator

|

48 ton/hour, 45.5 barg x 2 units

|

|

Auxiliary Gas Boiler

|

48 ton/hour, 45.5 barg x 1 unit

|

Project Owner : PTT Public Company Limited (PTT)

Construction Period: January 2008 - September 2009

Commercial Operation Date : May 2010

|

►►► Central Utility Plant 2 (CUP-2)

This Project is Auxiliary Boiler and Combined Cycle Plant that located at Rayong Province.

Project Description :The Plant comprises 2 Gas Turbine Generator (GTG), 2 Heat Recovery Steam Generator (HRSG), 1 Steam Turbine Generator and 1 Auxiliary Boiler.

Configuration

|

Gas Turbine Generator

|

Fr 6581-B, 38 MW x 2 units

|

|

Heat Recovery Stream Generator

|

140 ton/hour, 45 barg steam x 2 units

(full supplementary firing)

|

|

Steam Turbine Generator

|

38 MW x 1 unit

|

|

Auxiliary Gas Boiler

|

50 ton/hour, 45 barg x 1 unit

|

|

Temporary Auxiliary Gas Boiler

|

70 ton/hour, 45 barg x 2 units

|

Project Owner : PTT Utility Company Limited (PTTUT)

Construction Period : October 2006 - March 2009

Commercial Operation Date : May 2009

|

►►► Gas Turbine Replacement For SBIA

This Project located at Suvarnabhumi International Airport, Samutprakarn Province

Project Description : Erection the Gas Turbine units, EPC works for all related BOP, Testing & Commissioning for combined cycle plant.

Project size : 90 MW Net + 124 TPH Steam

Project Owner : District Cooling System and Power Plant Co., Ltd. (DCAP)

Commercial Operation Date : Unit 1 December 2011 and Unit 2 May 2012

|

►►► Cogeneration Power Plant Project For SBIA

This Project located at Suvarnabhumi International Airport, Samutprakarn Province

Project Description : This Power Plant is Cogeneration and District Cooling System.

Configuration

|

Gas Turbine Generator

|

22.0 MW x 2 units (AEG Kanis Frame 5) Supplied by Owner

|

|

Heat Recovery Stream Generator

|

42.5 t/h x 2 units

|

|

Steam Turbine Generator

|

12.0 MW x 1 unit

|

|

Auxiliary Gas Boiler

|

18 t/h x 2 units and 20 t/h x 2 units

|

|

Steam Absorption Chiller

|

1,500 RT x 3 units, 1970 RT x 2 units ≪for TG Catering≫

2,100 RT x 8 units (Stage1) + 2,310 RT x 2 units (Stage2) ≪for PTC≫

|

|

GIS

|

115kv Indoor 7 days

|

Project Owner : District Cooling System and Power Plant Co., Ltd. (DCAP)

Construction Period : January 2004 - September 2006

Commercial Operation Date : September 2006

|