Process Facility Services

Integrated Process Engineering fields are gathered round to serve customers’ needs.

Thai Shinryo has been providing the environments with a wide range of high-technology industries and special facilities. We are well known towards the advanced Heating, Ventilation and Air-Conditioning (HVAC) technologies such as Clean Rooms, Super Clean Rooms and Sophisticated HVAC in power plant business.

We design utility systems to serve all process equipments, production machines and production line.

Moreover, we also integrate the Control & Instrument for such systems.

Experienced Projects

►►► Cooling Water Process

We supply the start-up process changing range of cooling water temperature condition from brine to water as equipment required such as injection machines, washing machines, food process machines and oven machines, etc.

|

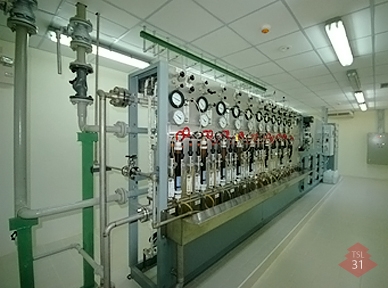

►►► Control and Instrument System

We build the conceptual design up to final design, installation and commissioning towards electric and instrument such as flow measurement, pressure measurement and correcting units, etc. following the Control & Instrument (C&I) system design.

|

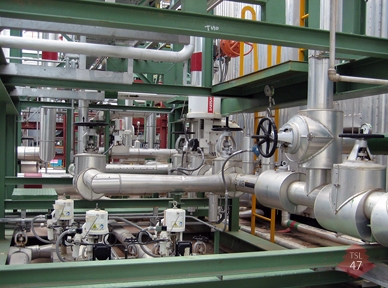

►►► Compressed Air

We supply both no-oil and oil flooded compressed air line systems with equipment and pipe working for assembling factories, car factories and clean room factories. This is also in gas compressor by steam in case of high pressure Natural Gas (NG). Pipeline system supplies equipments such as ones for gas turbine.

|

►►► Process Exhaust System

We design following purposes of usage such as oven machines, washing machines, soldering lines, weld lines, grinding lines, evaporation and abrasive blasting as your production required.

|

►►► Steam Utility Pipe Work

We design and build following the American Society of Mechanical Engineers (ASME) code in various pressure ranges such as 10 bars, 20 bars and 40 bars. Steam flushes (blows) to clean the steam pipeline. We support your plant with fire tube and water tube boilers with capacities of 10 ton/hr and up to more than 50 ton/hr.

|