Process Center (Theparak Factory)

We supply from material process to final process.

| Material Process |

|

Rough Cut & Machine |

|

Choice Heat treatment |

|

Finish Part |

|

Material Process・Heat Treatment

|

Slitter・Leveler

We import mother coil and we order coil center to slit・leveler・mini leveler for customer's request.

|

Sharing

We cut customer's request sheet size.

|

Band saw cut

We can cut wide range of round bar & Flat Bar.

Size:10mm ~ 750mm

|

|

Auto Circular Saw

Auto Circular Saw can cut round bar (flat bar) very accurate size and smooth surface.

Size:Ф10mm ~ Ф125mm

|

Straightening

Straightening for Round bar

Size:Ф10mm ~ Ф40mm

|

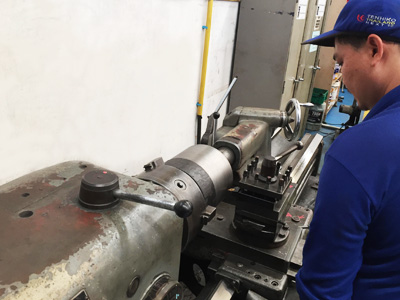

Manual Lathe

Manual Lathe use for rough cut and pre-process for CNC lathe.

Size:

Okuma. : Max Ф300mm

Toshiba : Max Ф1200mm

|

|

Gas / Laser cut

We can cut shape from customer's request.

|

Heat Treatment

We will suggest proper heat treatment form our Heat treatment network.

Vacuum type harden & temper / carburizing, Gas carburizing / nitriding, Salt bath, continuous harden & temper, Normalizing, Annealing, Coating, etc.,

|

Process for Part

|

CNC Lathe

Mori Seiki CNC is very accuracy cutting.

Size:

SL403B : Max Ф600mm

|

CNC Lathe (Milling type)

CNC Lathe process and Milling process can do same time.

Size:

NLX2500Y : Max Ф300mm

|

CNC Lathe (Takamaz)

It is suitable for mass production part.

Size:

GSL-10H : Max Φ160m

|

|

Machining Center

Finished Grinding to cylindrical shape.

Size:

V33 : Max 250 x 400 x 600mm

|

Wire Cut

We will do machine process to be customer's drawing.

Size:

FA20VS : 300 x 350 x 500mm

|

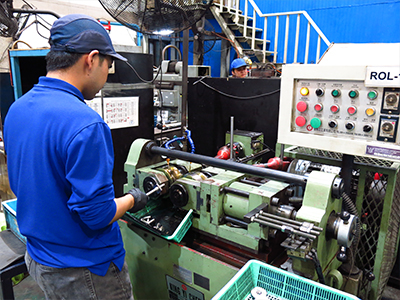

Rolling Machine

We process by dies for making thread of bolt.

Size:

YC-30 : Φ8mm ~ Φ30mm

|

|

Cylindrical Griner

Finished Grinding to cylindrical shape.

Size:

Max Dia. : Ф200mm

Max Length : 1000mm

|

Rotary Grinder

Finished Grinding to surface.

Size:Max Ф380mm

|

Surface Grinder

Finished Grinding to surface.

Size:Max 400mm x 700mm

|