For 25 years since its establishment in 1996, TRV has been improving its QCD and proposal capabilities to satisfy Japanese automotive We offer low cost and stable quality through our compounding technology and production technology (material, mold, molding) to meet various requirements (environment, chemicals, anti-vibration, etc.).

We will continue to strengthen our technological capabilities to meet the changing needs of the world, while striving to be company that is friendly to people and the environment.

TRV 's Strength

|

|

< Operation of more than 1,000 products >

・Automotive: Pedal cover, Bellows tube, O-ring, Packing, Slip seal, etc.

・Home appliances: Hose, Anti-vibration rubber, Packings Sealing cap, etc.

・Others: Pump, Water piping gasket, etc.

・Materials: Silicone, NR, NBR, EPDM, etc. Please feel free to ask.

|

|

< Development・Evaluation > < Development・Evaluation >

・We develop materials that satisfy customer requirements based on standardized basic formulations.

・In cooperation with external evaluation organizations, we respond to customers' evaluation requirements.

|

|

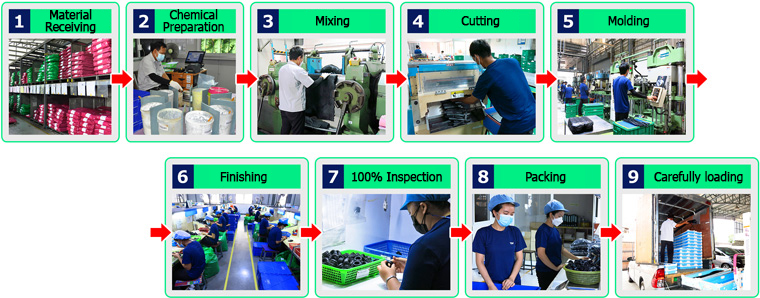

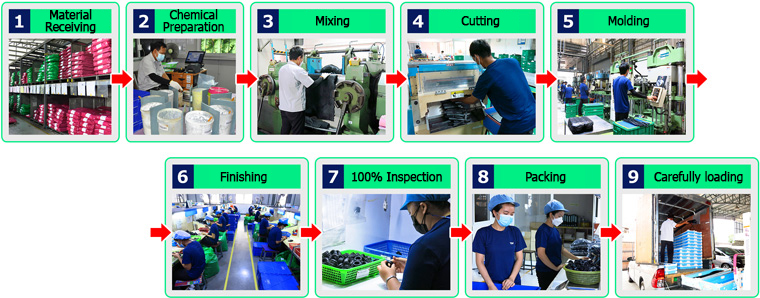

< Production >

・In-house integrated production (Compounding - Kneading - Molding - Finishing - Inspection) realizes low cost, quick delivery and

・Molding: Injection, extrusion, and compression are available to meet various specifications.

|

|

< Quality Control/Quality Assurance >

・ISO 9001 / IATF16949 / Green Industry certified

・We emphasize identification management, 4M change point management, and recurrence prevention management from the actual

・We have a system and structure for quick emergency response in case of emergency.

・ISO9001 / IATF16949 / ISO14001 / Green Industry / Carbon Footprint Certified

|

|

─ Production Process ─

< Development・Evaluation >

< Development・Evaluation >