DAIDO DMS (THAILAND) CO.,LTD.

Tool steels / Heat treatment / Surface treatment (Nitriding, TD processing and PVD coating)

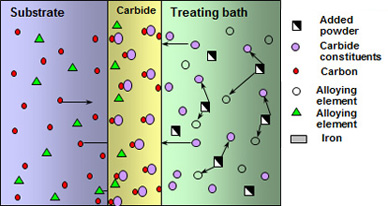

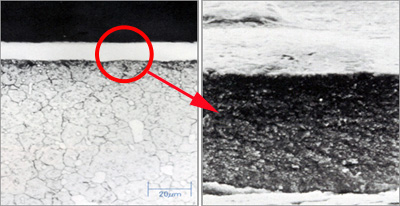

TD processWe offer TD (VC) treatment for cold pressing, which has excellent resistance to wear, galling, and melting damage. |

| TD processing applied parts●Drawing punch dies

|

Characteristics of TD process (comparison with other coating characteristics)

|

|

Comparison References

| TD | CVD | PVD | |

| Processing method | Thermal reaction, precipitation and diffusion | Thermochemical reactions | Plasma Reaction |

| Coating Layer | VC | Tic,Tin,TinC, etc. | Tin,TiAIN,CrN,DLC, etc. |

| Coating Color | Gray to black | TiC: Silvery white

TiN: Gold | TiN: Gold

TiAIN: Purple to black |

| Coating film hardness [HV] | 3200 to 3700 | TiC:3300-3700 | TiN:2200-2700 |

| Coating thickness [μm] | 6 - 10 | 7 - 10 | 3 - 5 |

| Processing temperature [℃] | 1000 to 1050 | 700 to 1100 | 200 to 600 |

| Dimensional Accuracy | △ | △ | ◎ |

| Adhesion | ◎ | ◎ | ○~◎ |

| Coefficient of kinetic friction | ○~◎ | TiC:◎ TiN:○ | TiN:○ TiAIN:○ |

| Mirror finish | ◎ | ◎ | ○ |

List of TD processing equipment for cold pressing

| Classification | Equipment name | Effective dimensions | Number of units | Maximum heating temperature | Ability |

| Processing furnace | TD (Toyota Diffusion Coating Process) Furnace | Φ400×600 | 2 | 1020℃ | 120Kg/Ch |

| Ancillary Facilities | Preheating Furnace | Φ400×600 | 1 | 850℃ | - |

| Tempering Furnace | Φ400×600 | 2 | 650℃ | - | |

| Cooling system | Φ510×810 | 1 | - | - | |

| Finishing cleaning tank | Φ510×810 | 1 | - | - |