DAIDO DMS (THAILAND) CO.,LTD.

Tool steels / Heat treatment / Surface treatment (Nitriding, TD processing and PVD coating)

PVD Coating |

By processing at temperatures around 500°C, a coating with excellent wear and galling resistance can be formed for high-precision molds.

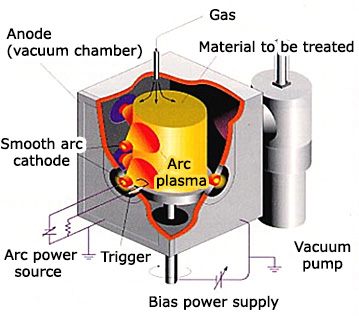

Multi Arc Sysetem |

Product Examples |

► Characteristics of each coating |

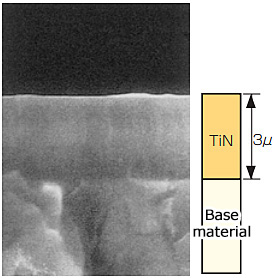

Base coating thickness: 2 to 4 μm |

|

►High Tensile Strength Steel Cerac (Improved TiN) |

As the strength of high-tensile steel sheets has increased in recent years, the load on dies and the demand for precision have grown, and the need for longer life through PVD treatment has increased. In order to improve life, we aim to increase the life of dies by minimizing coating defects.

In addition, by combining this with base nitriding (radical nitriding), we can expect to further extend life.

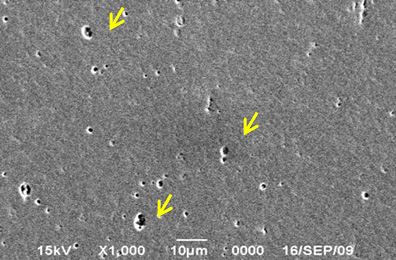

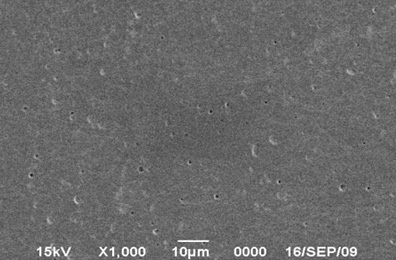

Conventional TiN |

|

High Tensile Strength Steel Cerac

|

Coating defects (pinholes) can cause adhesion of the workpiece and peeling of the coating.

1. Adhesion of workpiece | 2. Increase in adhesion | 3. Minor galling (coating peeling) |

Foreign object caught |

|

►Effective processing range |

・PVD treatment: φ720×800 - MAX500㎏ ・Nitriding: φ600×600 - MAX300㎏ ★Depending on the shape and size of the mold, it may not be possible to treat only the required parts.

|

|