DAIDO DMS (THAILAND) CO.,LTD.

Tool steels / Heat treatment / Surface treatment (Nitriding, TD processing and PVD coating)

Hot forging die manufacturing

We provide integrated manufacturing of hot die parts using Daido Steel.

|

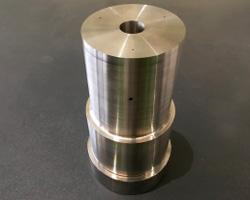

Examples of products to be machined

【Hot forging die parts】Forging die parts mainly for round objects |

|

|

|

|

|

|

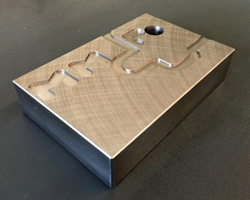

【Machining of jigs and small square objects (tapping, drilling, simple mill processing)】 |

|

|

Equipment list and processing capacity

| Maker | Facility | Spec | |

|---|---|---|---|

| Okuma | NC lathe

LB400C/1250 OSP Manufacturing date: 2006.12 | Chuck size: 10 inches

Center distance: 1250 mm (with core support) Main processing size: φ200×150 to φ35×300 (maximum processing diameter: φ300) |

| Okuma | NC compound lathe

LB3000EX-MW 500 OSP Manufacturing date: 2012.03 | Chuck size: 10 inches

Center distance: 500mm (without Y-axis) Sub-spindle (8 inches) Specifications Main processing size: φ200×150 to φ35x150 (maximum processing diameter: φ300) |

| Okuma | NC lathe

GENOS L3000-e OSP Manufacturing date: 2017.10 Body weight: 5,000kg | Chuck size: 10 inches

Center distance: 500 mm Main processing size: φ200×150 to φ35x150 (maximum processing diameter: φ300) |

| Okuma | NC lathe

LB4000EX OSP Manufacturing date: 2011.12 Body weight: 6,300kg | Chuck size: 12 inches

Center distance: 750 mm (with motor- controlled core stock) Main processing size: φ350×200 to φ80×500 |

| Okuma | Machining center

MILLAC44V FANUC Manufacturing date: 2011.03 | Table size: 630mm×400mm

Axis travel X: 560, Y: 410, Z: 410 Spindle: №40 120 to 12000min -1 Vice specifications: Jaw width 125mm, Jaw opening 256mm |

| Okuma | Machining center

MILLAC468VⅡ OSP-P500 Manufacturing date: 2024.08 | able size: 1050mm×460mm

Axis travel X: 820, Y: 460, Z: 450 Spindle: 50 to 15000min -1 |

| Sodick | small hole EDM

K1CN Manufacturing date: 2006.07 | Head travel distance X: 200mm, Y: 300mm, W: 230mm

Electrode attachment diameter: φ0.25~φ3.0mm |

| KEYENCE | Handy probe

3D measuring machine XM-1500 | Repeatability: ±3μm

Indication error: ±8μm Measurement range (mm): 300 x 250 x 150 (width x height x depth) ・Geometric tolerance measurement ・Deviation display (distortion direction/trend) |

| CAD/CAM | C&G CO., Ltd. | CAM-TOOL prime

CAD-Meistar | Modeling of 3D mold shape, CAM design, and machining center processing program support

|

| Sodick | small hole EDM

K3HS Manufacturing date: 2018.8 | Head travel distance: X: 300 mm, Y: 400 mm, W: 230 mm

Electrode attachment diameter: φ0.2 to φ3.0mm |

We also handle products other than samples for NC lathe processing, NC milling processing, and small hole EDM.

Please feel free to request a quote.