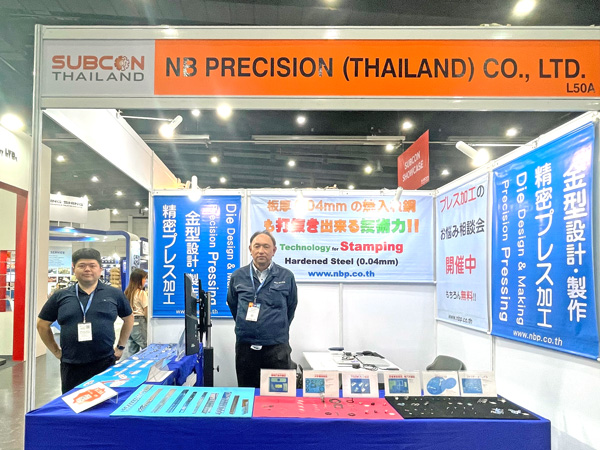

SUBCON THAILAND 2025 Exhibition Information |

|||

|

|||

Promotional video (Fujinomiya factory and Thai factory) |

|

Main production parts

|

|

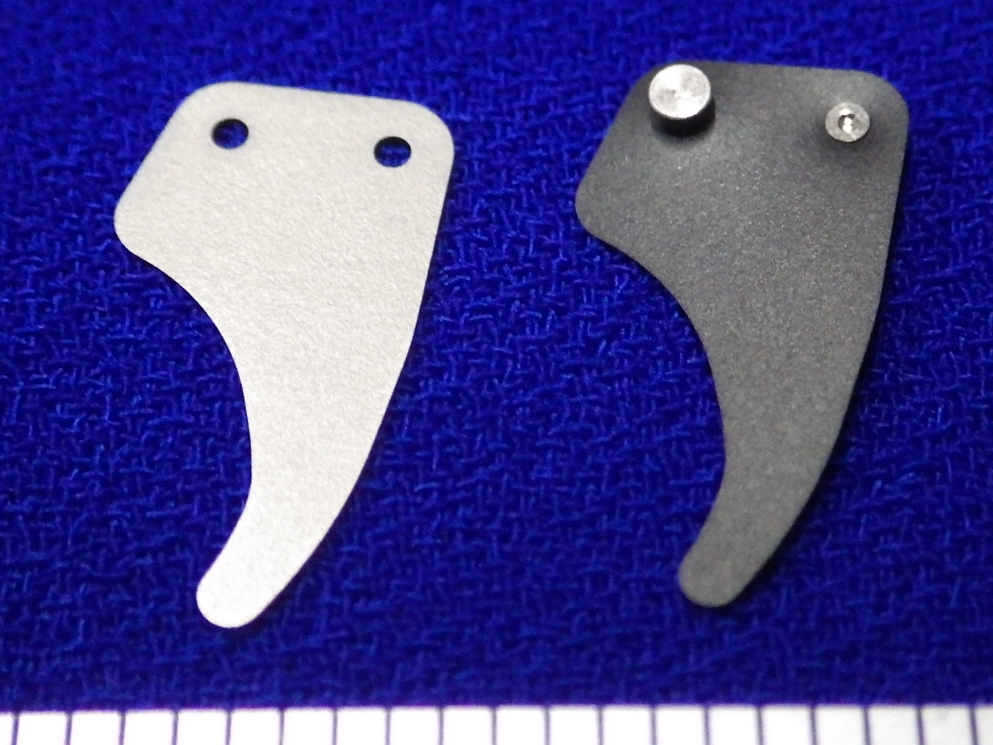

Aperture Blades (Camera parts) (quenched steel 0.04mm)Compound die with "Zero" clearance We have a particularly good reputation for precision blanking of thin sheets of hardened ribbon steel. We have been applying the technology that we have developed in Japan for many years here at our Thai factory. Of course, the dies are designed and manufactured at our Thai factory, and we also arrange painting and pin caulking in-house. |

|

|

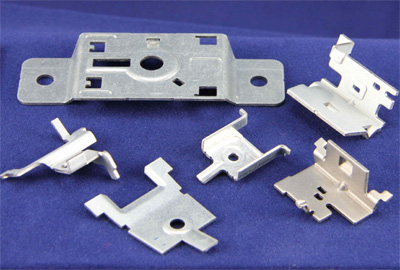

Motorcycle/Automobile partsProgressive die using original method Although it is a simple part, we have developed a unique construction method to mass-produce it, especially in order to obtain uniform height and diameter. The dies are also designed and manufactured at our Thai factory. |

|

|

Light electrical equipment / Home appliance partsProgressive press processing using a High-precision press machine In order to stabilize the dimensions of deformed processes such as coining and embossing, we use servo presses and link motion presses with high bottom dead center accuracy. |

|

|

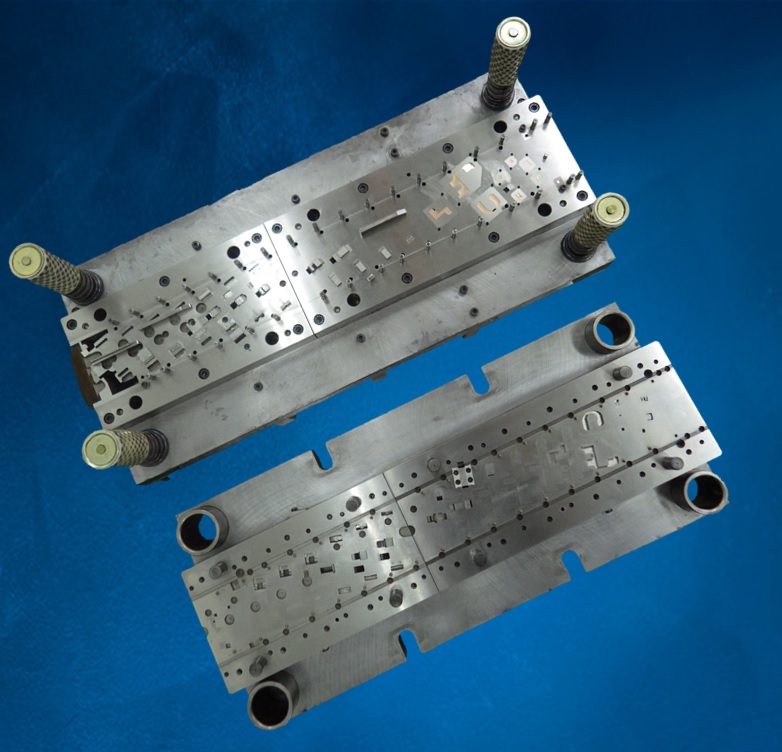

Progressive die design, production, and salesWe strive to manufacture dies that are easy to maintain All products are manufactured using the insert method, with an emphasis on ease of maintenance. In addition, by processing the punch, die, and plate using an ultra-high precision Wire EDM, the accuracy of thin press parts is particularly good.

|