Heavy-duty packaging materials (for export), recognized worldwide Tri-Wall Pak®

Tri-Wall Pack is synonymous with triple-wall reinforced corrugated cardboard, serving as a heavy-duty packaging material that replaces wood, steel, and plastic.

It meets global standards, including the U.S. federal specification PPP-B-640d, one of the world’s strictest and its superior quality is highly trusted across the logistics industry worldwide.

The double-wall “Bi-Wall Pack” is also widely used around the world as a heavy-duty packaging material.

Benefits of switching from wooden boxes to Tri-Wall Pack

In international transportation

Reduction of total logistics costs Reduction of CO₂ emissions

Performance capable of withstanding harsh transportation conditions

Achieving these goals, we provide solutions to our customers’ logistics challenges.

|

|

Lightweight

|

Compared to wooden boxes, the weight is only 1/3 to 1/4. In air transport, where freight charges are often based on weight, this provides a significant advantage, achieving substantial cost reduction.

|

|

Space-saving

|

Compared to wooden boxes, the external volume is greatly reduced. This improves truck and container loading efficiency, significantly contributing to lower transportation costs.

|

|

Reduction of packaging material costs

|

Compared to wooden boxes, we offer an average of over 15% reduction in material costs. Additionally, waterproof paper or film is not required.

|

|

High strength

|

Tri-Wall Pack has higher compressive strength than wooden boxes and can withstand stacking with approximately 10 times the compressive strength of standard cardboard.

|

|

Outstanding weather resistance

|

It uses a water-resistant long-fiber liner. Additionally, its moisture content is low at 8–9% (compared to over 20% for wooden boxes), and the pH is nearly neutral, providing excellent rust prevention.

|

|

CO₂ reduction

|

Reduced external volume and lighter weight help lower CO₂ emissions during transportation. Recycling also reduces CO₂ from disposal and incineration.

|

|

Environmentally friendly

|

Compared to wooden boxes, it reduces wood resource usage by 60%. It contains no hazardous substances such as lead or mercury, supporting companies green procurement initiatives.

|

|

|

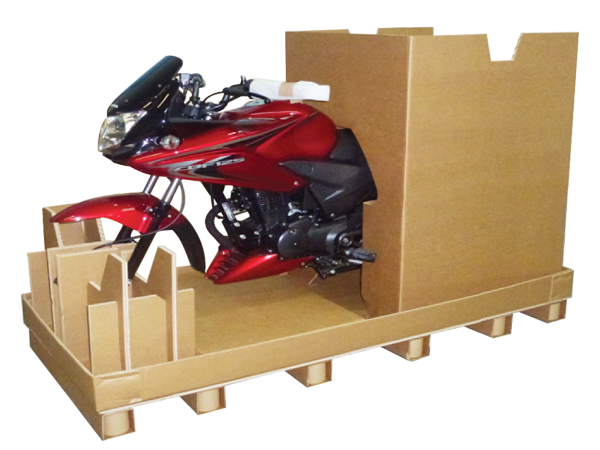

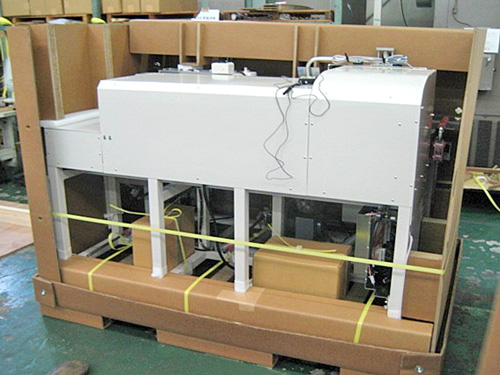

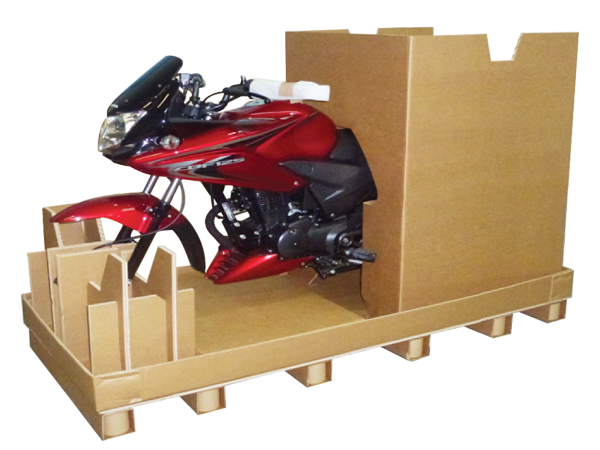

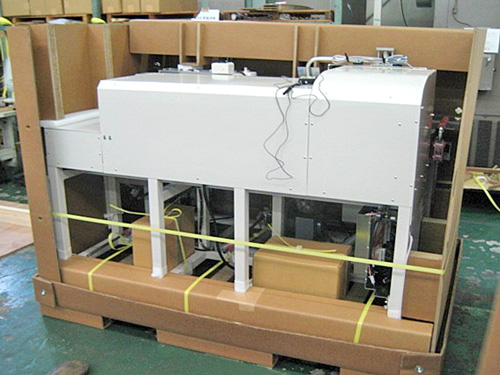

Packaging examples

Tri-Wall Pack can accommodate packaging for items of all shapes!

|

Applications: automotive parts, motorcycles, manufacturing machinery, precision instruments, electrical products, metal pipes, raw materials, liquids, fruits and vegetables, furniture, and more. Tri-Wall Pack is used for various packaging and packing needs worldwide.

Additionally, we offer 11G Tri-Wall Pack and 4G Bi-Wall Pack, which have obtained UN certification numbers required for exporting hazardous materials.

|

Exterior parts

|

Engine parts

|

Front bumper

|

|

Clutch parts

(Weight: 850 kg per box)

|

Motorcycle

|

Bus air conditioner condenser

(L:3m x W:1.5m x H:1m)

|

|

Enclosure

|

Long-length items (metal pipes)

|

Plastic raw materials

(Weight: 600 kg per box)

|

|

Hanger box

|

Grand piano

|

UN Tri-Wall Pak

UN-certified. Packaging containers for hazardous materials for export (Made in Japan)

|