Applicable field

■ Various die castings

■ Injection molding

■ Press molding

■ Mechanical structure parts

■ Electrical parts

| Heavy Duty Equipment and Mass Production Components. |

What is KANUC processing |

Basic and diffusion-grounded Kanuc treatment. No deformation or surface roughening. Cr-content in steel increases surface hardness.

[Application] VANE, Vent pipes, Molds, SUS parts, Cutlery

カナック処理の最も基本的な処理で拡散層を主体とし変形、肌荒れが無く、鋼中のCr量により表面の硬さがアップ。

【使用用途例】VANE・ベント管・成形金型・SUS部品・刃物

Features

| ||||||||||||||||||||||||||

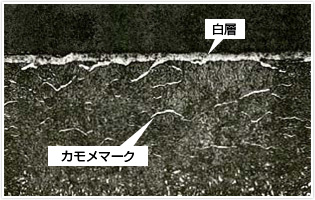

特徴 ■ 表層に脆い窒素化合物層(白層)が生成しにくい ■ クラックを進展させるカモメマークが生成しません ■ 比較的浅い硬化層(拡散層)になります ■ 面荒れをおこしにくい ■ 寸法変化量が小さい ■ 溶接時にボイド等の欠陥をおこしません ■ 付き回り性が良好で、細穴や異形状にも均一に処理が可能です ■ 繰返し処理が可能です ■ 各種処理と組合せた複合処理が可能です | ||

使用目的 ■ 耐摩耗性向上 | 適応分野

■ 各種ダイカスト ■ 射出成形 ■ プレス成形 ■ 機械構造用部品 ■ 電機部品

| 主用途例

■ 鏡面金型 ■ シボ金型 ■ 射出成形用の構成部品 ■ 各種ダイカスト用の構成部品 ■ 粉体輸送管 ■ 粉砕機スクリーン ■ 搬送用チェーン ■ 耐摩耗部品 ■ 高合金鋼の刃物類

|

Applicable field

■ Various die castings

■ Injection molding

■ Press molding

■ Mechanical structure parts

■ Electrical parts

Main usage example

■ Mirror mold ■ Grain mold

■ Components for injection molding

■ Components for various die castings

■ Powder transport pipe

■ Crusher screen

■ Conveyor chain

■ Wear resistant parts

■ High alloy steel cutlery

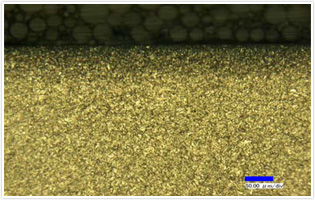

Microscopic structure(SKD61) |

| KANUC processing | Gas nitrocarburizing treatment |

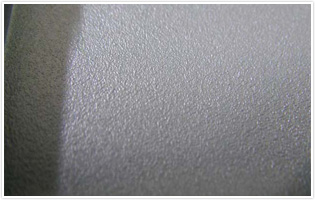

Appearance of mirror mold and grain mold |

| Mirror finish is required after KANUC treatment | Polishing is required after KANUC treatment |

Steel Grades suitable for Kanuc Application |

| Steel Grade | Japanese Industrial Standard | Cr content % | Hardness Hv 100g |

| Cold Working Tool | SKD11, SLD8, DC53, SKD12 | 5.0 ~ 14.0 | 1,000 ~ 1,400 |

| Hot Working Tool | SKD4, SKD5, SKD7, SKD8, SKD61, SKD62 | 2.0 ~ 6.0 | 800 ~ 1,100 |

| Plastic Molding Steel | Cr-Mo tic, 13Cr-Stainlesitic, Ni-Cr-Mo tic, Ni-Cr-Mo-Cu tic | 0.4 ~ 13.0 | 600 ~1,400 |

| High Speed Steel | SKH51 ~ 59, SKH2, SKH3, SKH4, SKH10 | 3.5 ~ 4.5 | 1,200 ~ 1,400 |

| Powder High Speed Steel | HAP, ASP, DEX, FAX, SPMR8 | 4.0 ~ 6.0 | 1,200 ~ 1,400 |

| Cr-Mo Steel | SCM435, SCM440, SCM445 | 1.0 ~ 2.0 | 600 ~ 800 |

| Malaging Steel | YAG, MAS1, KMS-CF90, QM300, NAG21 | ~ 0.1 | 1,000 ~ 1,200 |

| Austenitic Stainless Steel | SUS303, 304, 316, 316L | 16.0 ~ 24.0 | 1,200 ~ 1,400 |

| Ferritic Stainlass Steel | SUS405, 410L, 430, 430F | 10.0 ~ 30.0 | 900 ~ 1,200 |

| Martensitic Stainless Steel | SUS410, 416, 420J2, 420F, 440A, 440C | 10.0 ~ 20.0 | 900~ 1,400 |

| Martensitic Heat Resisting Steel | SUH1, 3 4, 11 | 7.0 ~ 20.0 | 1,000 ~ 1,400 |

| Austenitic Heat Resisting Steel | SUH31, 36, 37 | 15.0 ~ 25.0 | 1,000 ~ 1,400 |