OKI SYSTEMS (THAILAND) LTD.

Sales of color label printer and compact office printer for increased efficiency

Case Study

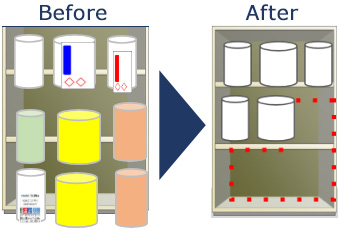

▶ Chemical(GHS label) |

| 【Simpler inventory management with in-house GHS labels!】

|

Previously, barcodes and variable information were printed in a single color on pre-printed synthetic paper labels. However, there were issues with the print quality of small text and barcodes. After introducing the new system, even fine text and barcodes can be printed sharply, resulting in higher quality for our in-house labels. In addition, since we can now print variable information in color, it is no longer necessary to remake several types of pre-printed labels each time display standards change due to legal revisions. |

|

user comment |

▶ Food & Biverage |

| 【High-durability, diverse labels produced quickly !】

|

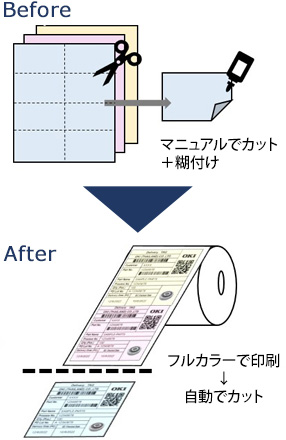

Previously, we used an A4 printer to print limited-time product labels side by side on label sheets, but applying each sheet label by hand was very time-consuming. After introducing the new system, we can print exactly the number of labels needed and have them automatically cut and dispensed one by one, greatly improving the efficiency of manual application. Additionally, we can now produce transparent film labels in-house, which we used to outsource, helping us reduce lead times. |

|

user comment |

▶ Automobile(Identification Label) |

| 【Reduce material and cutting costs for ID labels!】

|

Unlike inkjet printers, no special paper is required, so we can use inexpensive media and reduce running costs. The faster printing speed has also helped cut down on work time. On-demand printing allows us to produce only the quantity needed, significantly reducing paper waste compared to using sheet labels. |

|

user comment |

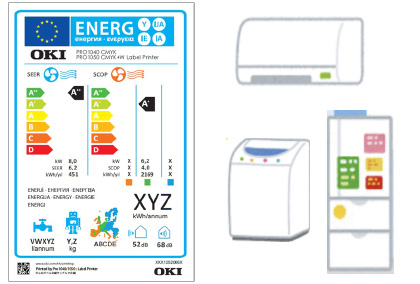

▶ Appliances:(Energy Label) |

| 【Efficient production of diverse energy-saving labels!】

|

Previously, we used a printer that couldn’t cut labels individually. After introducing the new system, we can now handle both roll-to-roll (without cutting) and custom-quantity cutting, allowing us to produce exactly the number of labels we need, when we need them.Compared to before, the in-house production rate of labels has increased and work efficiency has improved. |

|

user comment |

▶ Printing |

| 【Able to meet diverse, small-lot printing needs!】

|

Previously, we handled small-lot printing of around 100 to 500 sheets with analog printers, but plate changes and color matching by skilled workers were time-consuming, and there was a lot of paper waste. After introducing the new system, plate changing and manual color matching are no longer necessary, reducing workload and eliminating paper waste, which has improved profitability. Additionally, because variable color labels can now be produced one at a time, we no longer need to manage pre-printed rolls placed by customers, and the required storage space for roll paper has also been reduced. |

|

user comment |

▶ Other(Retail) |

| 【Print shelf tags and POPs in limited space!】

|

In urban stores, installation space is limited, so we needed a printer that could reliably operate in shelf-sized spaces. In drugstores, product prices change frequently. Competing with rivals often depends on how quickly we can respond with price adjustments. Once the price is changed, it’s crucial to display an eye-catching POP in front of the product as quickly as possible. We are impressed by the vivid reproduction of "red" with OKI printers. |

|

user comment |

▶ Other (Distribution/Retail): New Case Study of Introduction in Thailand |

| 【In-house production of original T-shirt printing and long-format POP reduces outsourcing lead time and costs.】 |

|

|

With special white printing, it is now possible to create designs that stand out even on dark-colored T-shirts such as black or navy. Since the service can be completed in-store, orders from short-stay tourists have increased. In addition to providing T-shirt printing as a customer service, the store is now also able to print promotional materials in-house. |

|

MUJI |

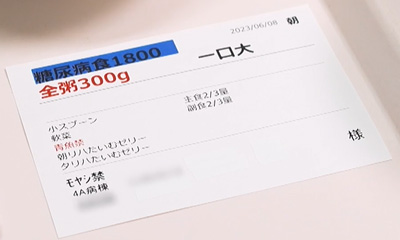

▶ Other(Medical, prescription bags, and meal cards) |

| 【Stable operation for high-volume printing!】

|

We print about 600-700 pages per day for health checkup guidebooks, questionnaires, and result reports. With our previous printer, paper jams occurred frequently and removing stuck paper was troublesome. After switching to OKI printers, paper jams have become less frequent, and even if they do occur, the simple design makes removal easy. |

|

user comment |

Prices and warranty details differ from those in Japan. Please contact your dealer for more information.