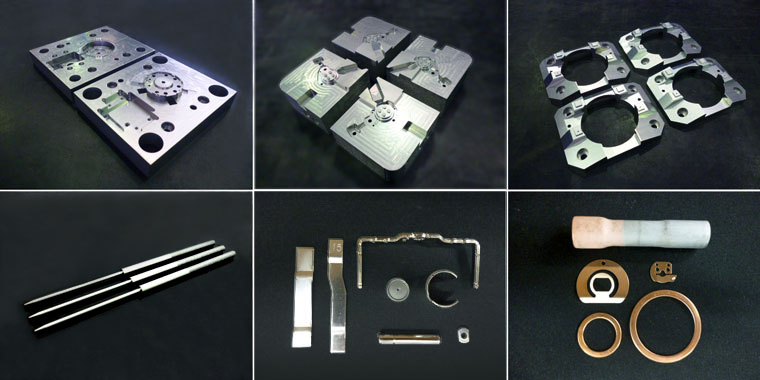

Business Description |

■Quenching/Tempering

Cooling can be done by using oil or pressurized gas.

For cooling by gas, nitrogen or argon can be selected, depending on the types of material to be hardened.

■Annealing

Magnetic annealing will not cause oxidation between grain boundary, therefore good magnetic properties are obtainable.

Spheroidizing treatment and Stress relief can also be carried out.

■Solution/Aging treatment

Austenitic stainless steel, nickle alloy, precipitation hardening stainless steel and beryllium copper can be treated.

■Sub-zero treatment, Super sub-zero treatment

Temperature for heat treatment can be reduced to a minimum -150℃

This will prevent precision parts and moulds from changing in dimension over the years, while wear resistance is also improved.

■Nitriding

This is heat treatment during which hard metal nitrite is formed on the surface of metal.

This will improve wear resistance and fatigue strength. Nitriding for titanium can also be carried out.

■Vacuum Carburizing

The surface of the carburized product is clean and no defects such as grain boundary oxidation.

Narrow gaps and deep blind holes can be carburized uniformly.

■Brazing

Brazing can be done by using a vacuum furnace. As a result, distortion will be minimized and flux is not required.

By the effect of degassing, an attractive and clean surface is obtainable.