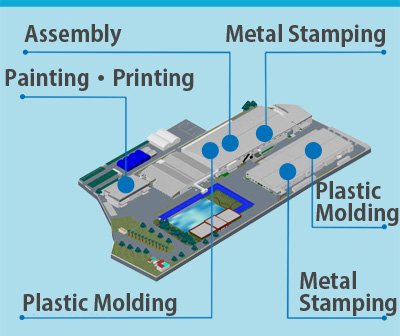

METCO Factory 2It is positioned on the mother factory in the factory of the largest. ■Operation started:September, 1990 |

|

Assembly |

|

CD changer for automobile |

Display unit for automotive |

Camera top cover unit |

LCD unit for DV cam |

|

Key less entry |

|

Metal Stamping |

|

Chassis for IDC |

Stocker tray |

|

|

Plasting molding |

|

Suspension Chassis |

Escutcheon |

|

|

Painting / Printing |

|

ETC |

LCD unit for DV cam |

|

|

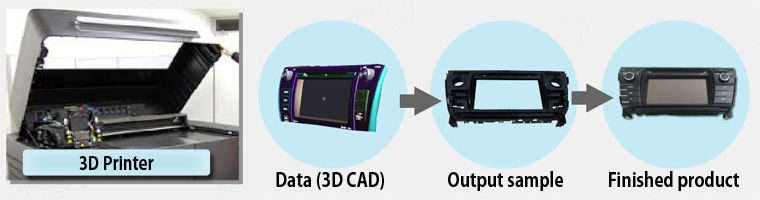

3D printer |

|

It can have a noticeable effect on production start-up and is, or hot to rapidly prototype in the development stage of the product. Quickly in METCO, introducing advanced 3D printer, it is conpatible with this problem. Prototype of the mold is less possible in the plastic parts in particular, to contribute to cost reduction. |

|

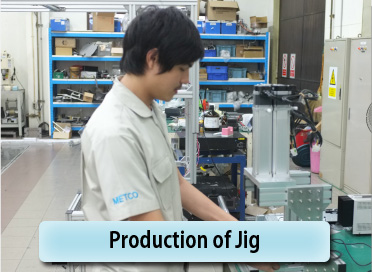

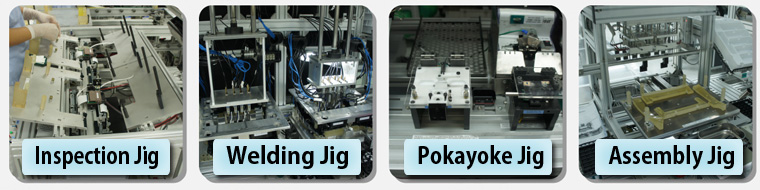

JIG design |

|

Important in the assembly is jig. Taking advantage of know-how and experience to date, we have been producing and designing the best jig in the process. |

|

QAIt is a measurement technology's support behind the manufacturing. Management of dimentional accuracy is important for a resin molded article and press products we deal in particular. Various instruments METCO has been active in the field. |

|

CNC 3D measuring instrument |

3D laser scanner |

Non-contact 3D measuring device |

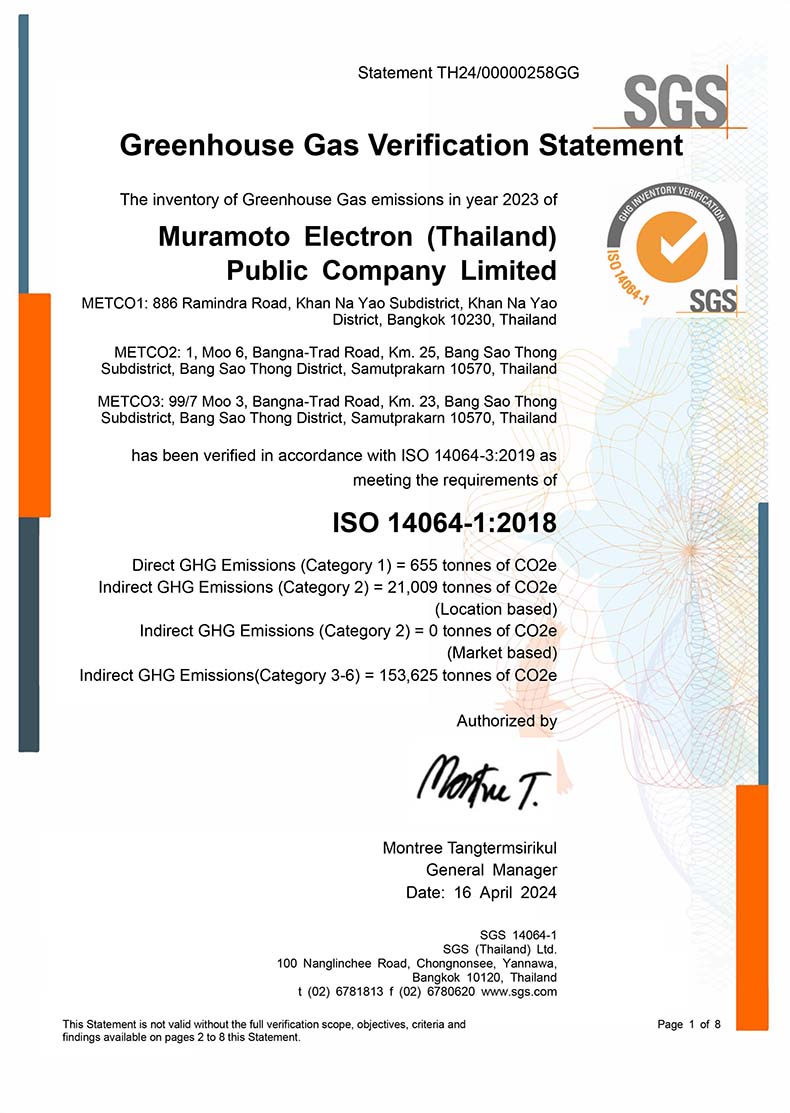

ISO Certificate |

|

ISO 9001:2015 |

ISO 14001:2015 |

IATF 16949:2016 |

ISO 45001:2018 |

ISO 14064:2018 |