Technology Introduction

Aluminium

Advantages of forging |

|

◆ |

Since the material can be formed into a shape close to the final product, there is little material waste. This leads to material savings. |

|

◆ |

Because the shape matches that of the mold, there is no dimensional variation, and accuracy comparable to machining can be achieved. It also enables rapid production of identical shapes. |

|

◆ |

Metal flow can be aligned with the product shape, resulting in increased strength. With improved strength, it becomes possible to establish metal thinning. |

|

◆ |

By applying pressure, the material structure becomes dense and free from internal defects. Since there are no defects such as casting voids, it is possible to maintain high product quality. |

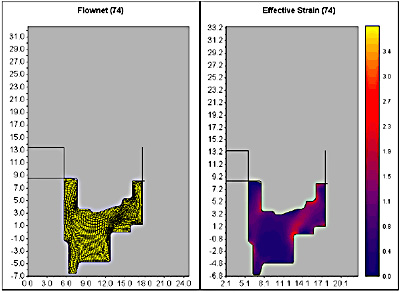

Forging analysis |

Our company conducts forging analysis to shorten the development time from evaluation to mass production. Simple shapes are analyzed in 2D, but for irregular and complex shapes, 3D analysis is conducted for prior verification.

|

|