Custom made machines

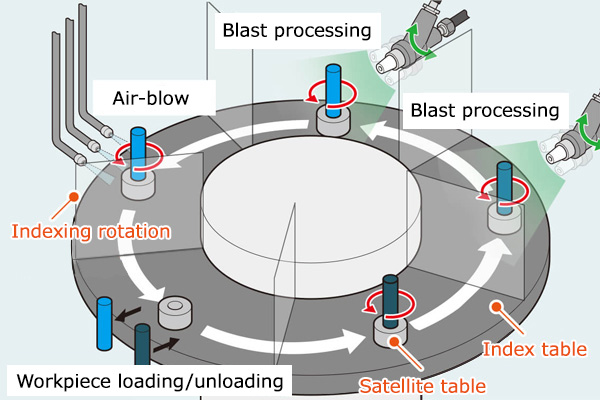

GT series

|

|

||||||

|

|

|

||||||

|

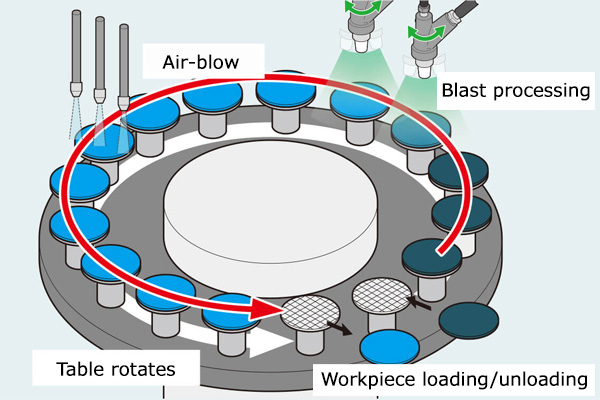

Planetary table type in which, workpieces are carried into machine cabinet by index table which rotates intermittently and, satellite tables on the index table rotate during blast processing or air-blow. |

|||||||

B / BAR series

|

|

||||

|

|

|

||||

|

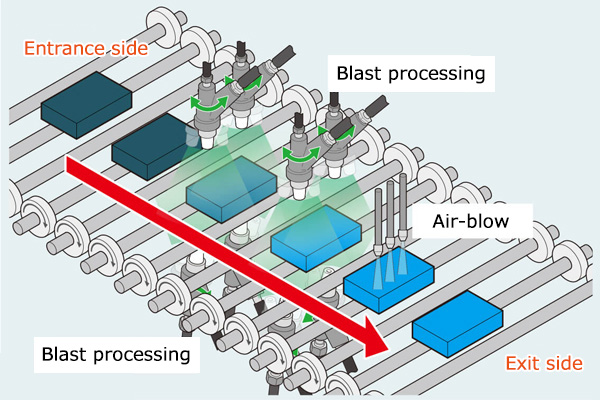

Workpieces placed on the conveyor on the entrance side are carried into machine cabinet and come out from the exit side, after performed with blast process and air-blow. |

|||||

RB series

|

|

||||

|

|

|

||||

|

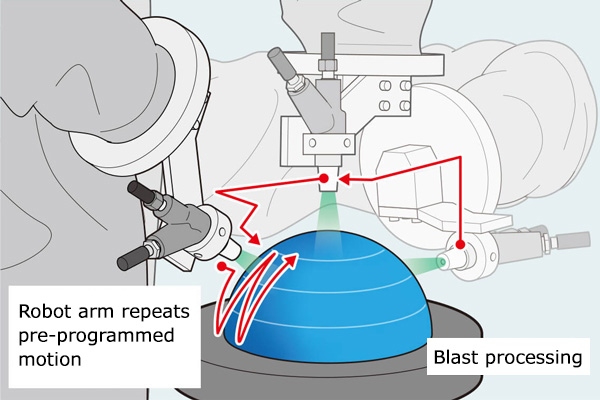

The machine performs processing by blast nozzle held by an articulated robot arm that can make flexible actions like human. |

|||||

ATCM series

|

|

||||||

|

|

|

||||||

|

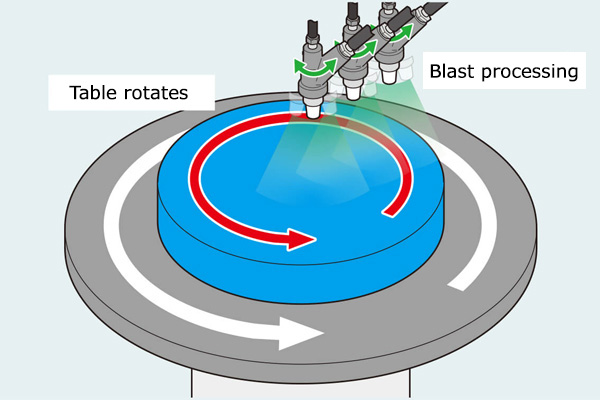

This is simplified automatic machine that performs uniform processing over the rotating table on which the workpieces are placed, when the machine is started. Nozzle motion and number of nozzles are customer option in accordance with shape and number of workpieces to be processed. |

|||||||

DT / RBT series

|

|

||||

|

|

|

||||

|

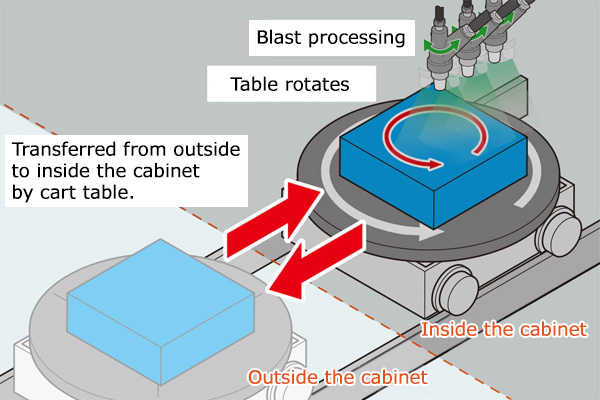

Cart table type machine suitable for large and heavy weight work. By setting the work on the table at side platform and pushing start button, operations including moving the cart, opening/closing slide door, blast processing and table rotation during processing are all performed automatically. |

|||||

ATV series

|

|

||||

|

|

|

||||

|

Batch processing system with which, workpieces are set on small tables with vacuum jigs to be held by vacuum which are located at circumference of high-speed turning table. After all workpieces are set, processing and air-blow will be performed for set time. |

|||||

YK series

|

|

||||

|

|

|

||||

|

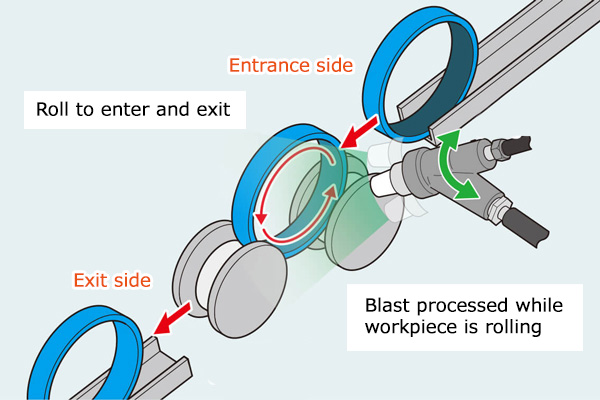

Cylindrical workpiece is set at loading chute and thrown into the process chamber one by one. Workpiece is processed while rotating on the roller part in the chamber. |

|||||

BL series

|

|

||||

|

|

|

||||

|

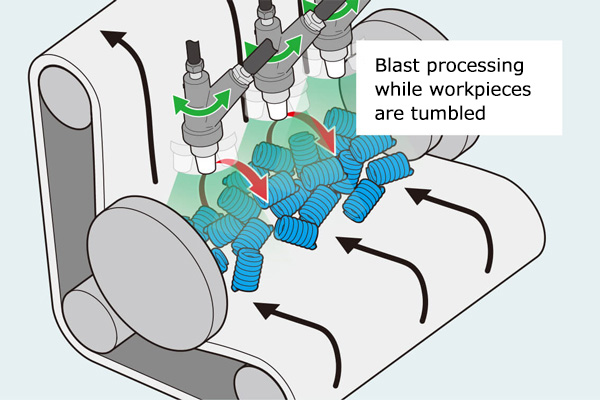

About 12L to 22L volume of workpieces are thrown in and processing is started. Blast processing is performed by 2 to 4 oscillating guns for workpieces being tumbled on the tumbler belt. |

|||||

LD series

|

|

||||

|

|

|

||||

|

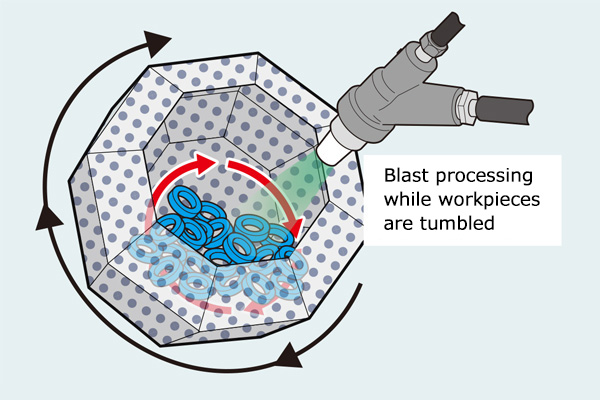

About 0.4L to 0.6L volume of workpieces are filled and processing is started. Blast processing is performed with a fixed gun for workpieces being tumbled in a rotating barrel cage. |

|||||

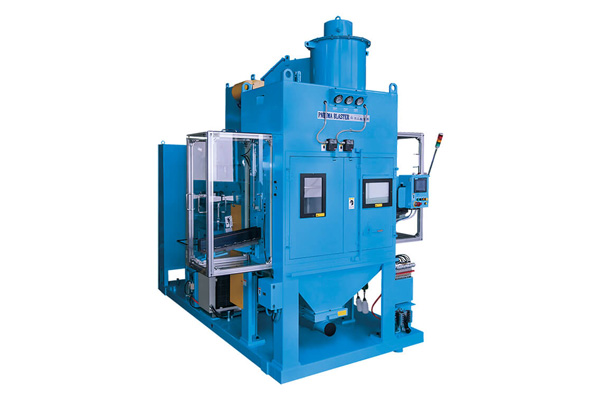

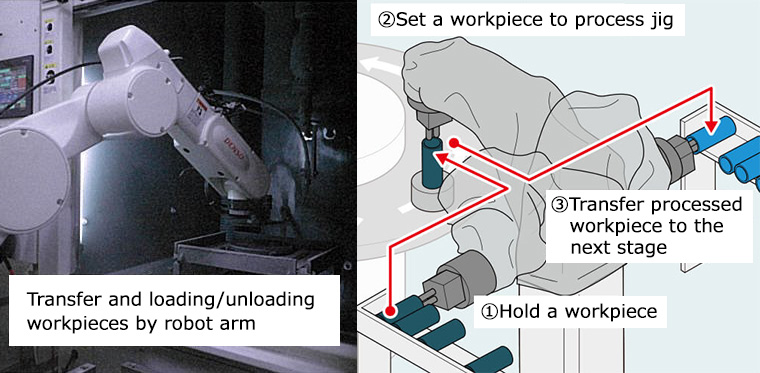

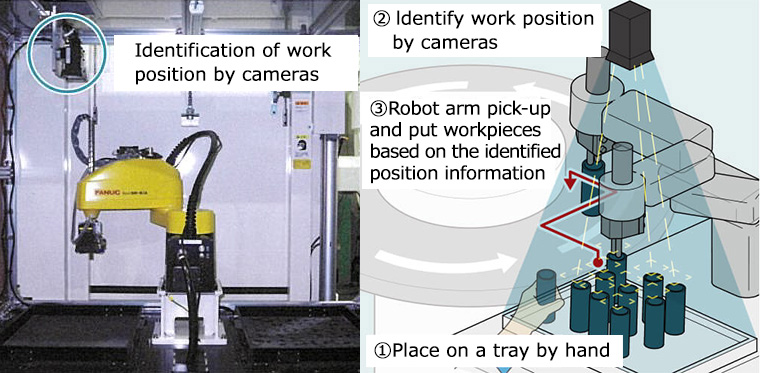

Machine with loader/unloader

|

|

||

|

|

|

||

|

Fully automated blasting process is available by combining with loading and unloading robots or with loader and unloader system, in case further promotion of automation or man-power saving is required, more than just blast processing by a blast nozzle mounted on the robot wrist. |

|||

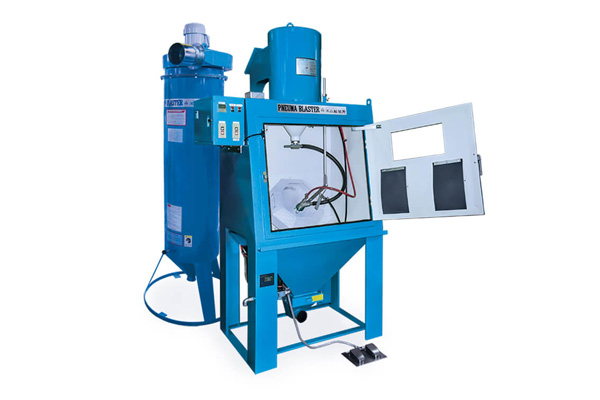

Manual machine series

|

|

||

|

|

|||

|

General purpose blast machines which can be used for industrial production line can be installed at low cost. Blast processing work under clear view and flexible processing is available with the blast nozzle flexibly moving manually by hand in accordance with various workpiece shapes. |

|||