CASTEM (SIAM) CO., LTD. / CASTEM (THAILAND) CO., LTD.

Lost Wax Precision Casting - MIM (Metal Injection Molding)

What is MIM (Metal Injection Molding)?

CASTEM's MIM technology has been independently researched and developed, and it's patented in the United States.

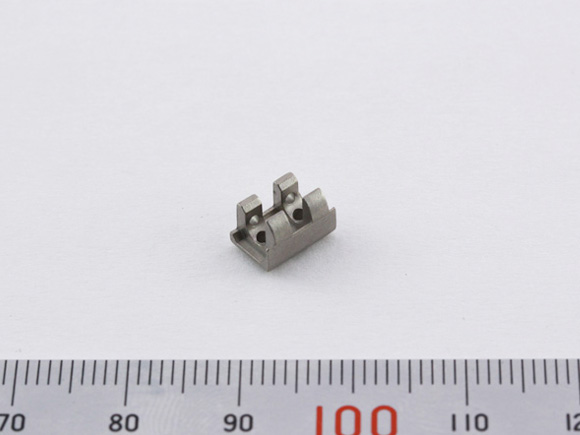

We can manufacture small products with complex shapes and thin walls that other companies cannot manufacture.

► Features of our MIM |

| Quantity | Small to large lots (dozens to tens of thousands of pieces) |

| Shape | Suitable for small products with difficult-to-cut shapes |

| Material | Mainly stainless steel, but also alloy steel and tool steel. |

| Appearance | Smooth finish below 3.2a |

| Strength | High strength with density over 95%. |

Excellent mechanical strength because its density reaches over 95% and its vacancies are spherical and independent. |

The body made by standard sintering has poor mechanical strength properties because its density reaches only 88% and its vacancies exist along the grain boundary irregularly. |

It indicates properties similar to that of molten material such as torsion and spring. (The products in the photo are made of SUS304) |

► Material / Tolerance |

|

|

||||||||||||||||||||||||||||||||

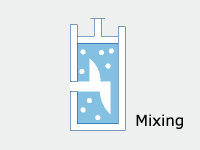

► MIM Manufacturing Process |

|

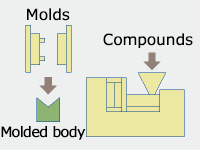

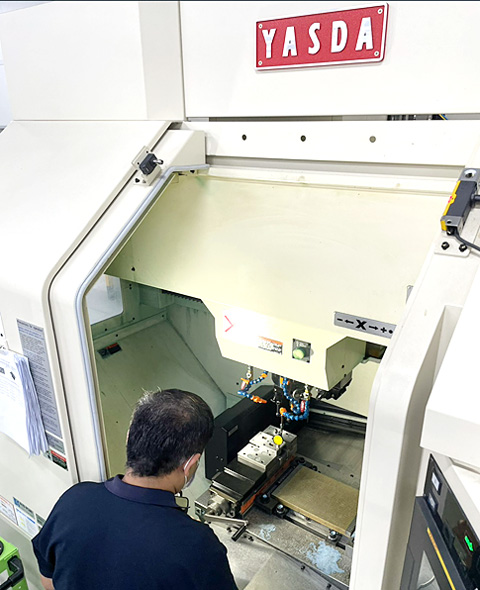

▶Die Design and Manufacturing

|

▶Injection Molding

|

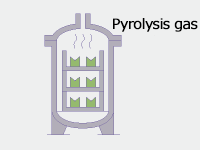

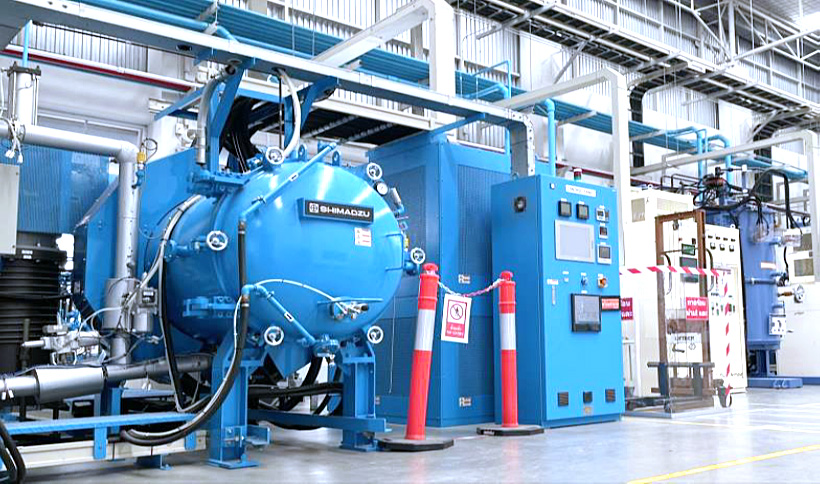

▶Dewaxing

|

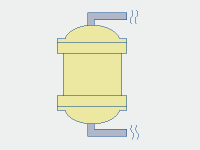

▶Sintering |

▶Inspection (Appearance, Dimensions) |

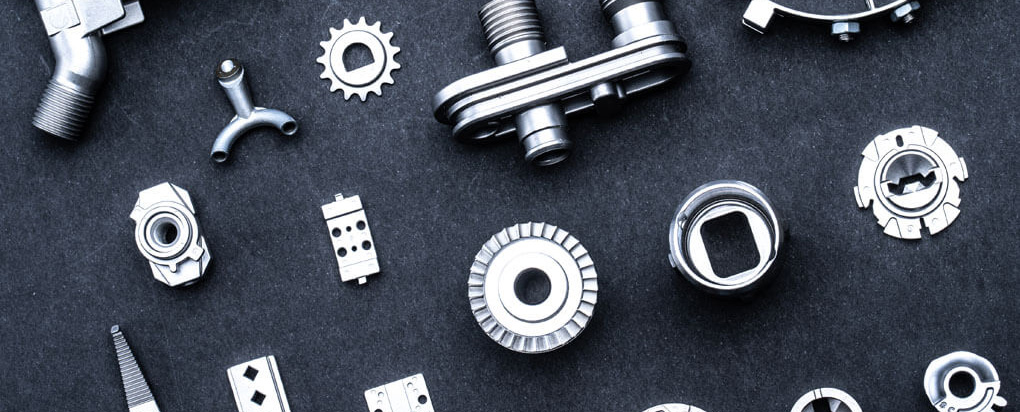

► MIM Product Examples |

|

|

|

|

|

|

||