CASTEM (SIAM) CO., LTD. / CASTEM (THAILAND) CO., LTD.

Lost Wax Precision Casting - MIM (Metal Injection Molding)

Silicone Rubber Casting

Silicone Rubber Casting

What is Silicone Rubber Casting?

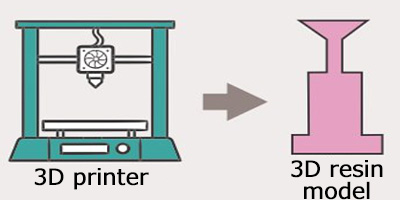

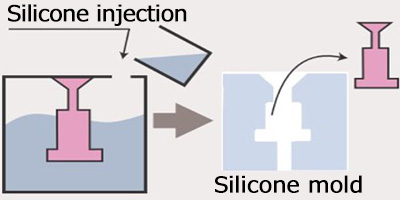

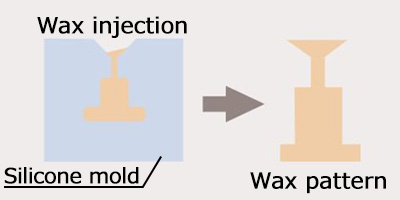

Silicone rubber casting method uses molds made by silicone rubber instead of metal molds in the lost wax process.

Features of our Silicone Rubber Casting |

| Quantity | Small lots (less than 100 pieces) |

| Shape | Approx. Max Size 60 cubic mm, Complex shapes that are difficult to create with molds can be produced |

| Material | Various types of steel, stainless steel, and aluminum |

| Casting surface | Dependent on the accuracy of the 3D printed model, stacking is visible. |

| Accuracy | Low precision because it depends on the precision of the 3D printed model. If accuracy is required, additional machining may be necessary to achieve the required dimensions. |

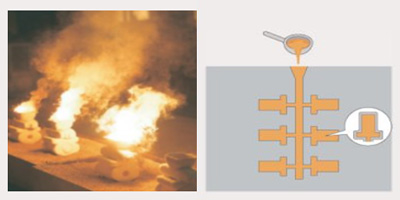

Silicone Rubber Ccasting Manufacturing Process |

|

Materials |

|

|

Silicone Rubber Casting Product Examples |

|

Aerospace part

|

Shachihoko

|

Notes on Digital Casting / Silicone Rubber Casting |

|

1. Dimensions The dimensional precision required for industrial products may not be achieved since it depends on the accuracy of the 3D printed model. As a countermeasure, additional machining may be necessary to achieve the required dimensions. |

|

2. Casting Surface Surface roughness also depends on the accuracy of the 3D printed model, so it is not equivalent to lost wax products. |

|

3. Materials Not all 3D printed models are suitable for use in digital casting. Some materials may not work well due to issues like residue or expansion during combustion. |