TRIGO PERFORMANCE &

CUSTOMER SATISFACTION

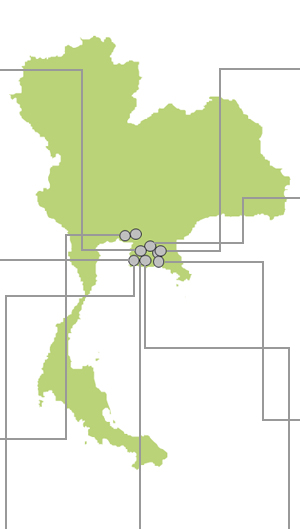

TRIGO THAILAND OEM FOOTPRINT (PERMANENT SITE) |

|

|

|

|

|

|

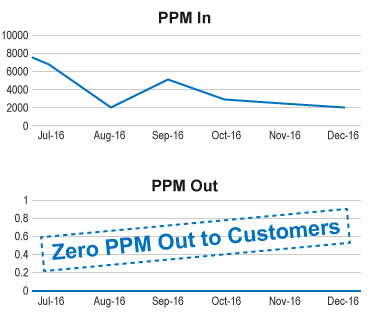

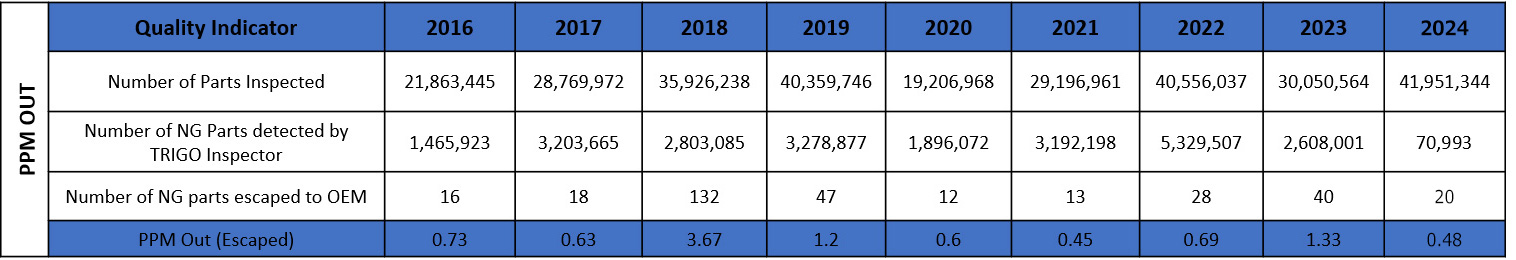

TRIGO Thailand Quality Performance |

TRIGO THAILAND

RELIABLE QUALITY SERVICES

A Trusted Name in 3rd Party Quality Services

We aim to be an active partner with you in assisting to meet our common objective: ZERO DEFECT.

SUCCESSFUL FIREWALL, Inspection & Containment |

|

|

CUSTOMER1st Tier Automotive CHALLENGE

SOLUTIONTRIGO Team provide firewall 100% inspection at 1st Tier Supplier.

ACHIEVEMENT

|

|

TRIGO ONE STOP

|

|

|

CUSTOMEROEM and 1st Tier Automotive Manufacturer CHALLENGE

SOLUTION

|

|

SUPPLIER AUDIT & ASSESSMENT |

|

|

CUSTOMEROverseas 1st Tier Automotive Manufacturer CHALLENGE

SOLUTION

ACHIEVEMENT

|

Client Feedback" ... I would like to say thanks so much for your audit services and your communication way during two days audit. I can say you are very professional in audit and your comments and advices help us much in term of concept and improvement opportunity..."

General Manager |

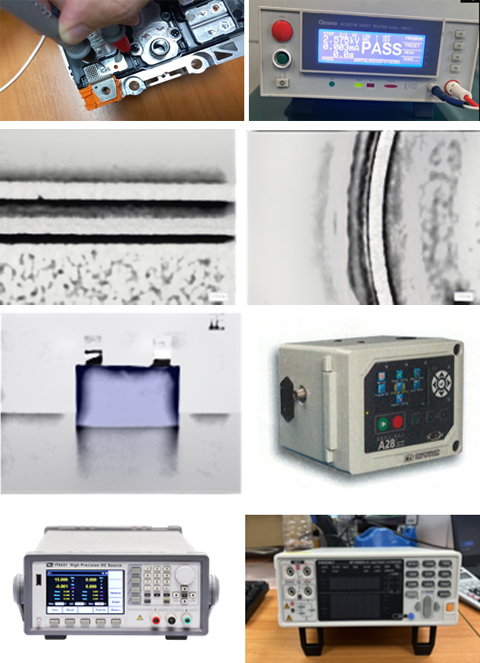

TRIGO EV BATTERY MODULE AND CELL ANALYSIS |

|

|

EV BATTERY MODULE AND CELL ANALYSIS

MODULE ANALYSISModule Analysis 9+1 Items :

Disassembly Battery module to able to continue analysis on Cell levelCELL ANALYSIS Cell Analysis 8 Items :

|

|

KEY ACHIEVEMENTS & RESULT

- Able to detect problems quickly and immediately

- Minimize damage or loss to OEM

- Shorten operating time from having to send the Module back to the country of manufacture for analysis But now Trigo can use the tool to analyze problems and report all results to customer

●

●