Nissin Electric (Thailand)Co.,Ltd.

Metal Part Processing, PVD Coating, Electric Substation Equipment

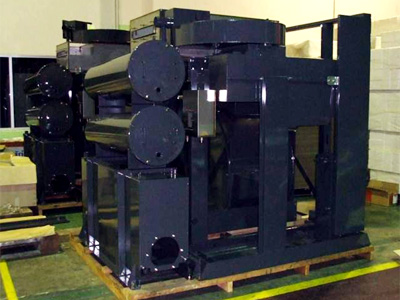

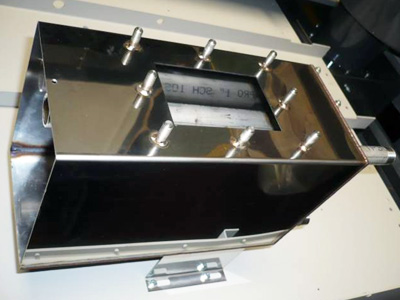

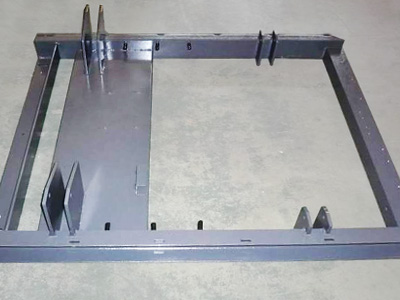

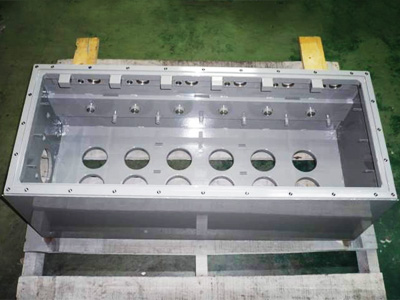

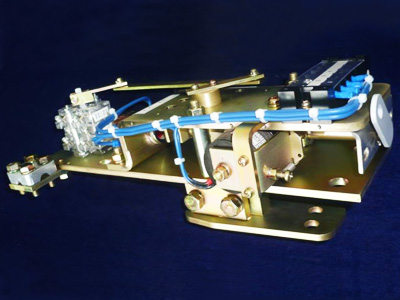

Metal Parts Manufacturing and Assembly

We produce goods of Japanese quality at prices comparable to those charged in Thailand and ship them both domestically and abroad.

We produce goods of Japanese quality at prices comparable to those charged in Thailand and ship them both domestically and abroad.

| To fabricate equipment and parts of several types in small lots, please leave the material selection, processing, and assembly to us. |

| We manufacture equipment and parts for all industries on a one-stop basis, with know-how in power equipment manufacturing and extensive facilities. From material procurement to delivery, please leave everything to us. |

| Please feel free to contact us regarding support that meets your needs, such as parts processing, semi-finished product equipment, and finished product equipment. We use a flexible system to respond to customer orders.

|

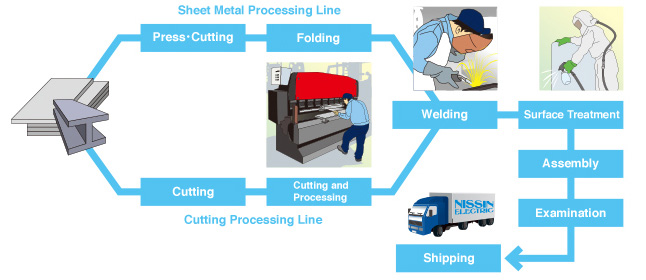

Manufacturing for equipment and parts flow |

One of company in Thailand with numerous machines and equipments.

Our strength is the wealth of tools and equipment that enables consistent in-house manufacturing. Both the sheet metal processing line and the cutting processing line are equipped with a system that can handle all kinds of products. Therefore, from material acquisition to surface treatment, assembly, inspection, and delivery, you can put your complete trust in us.

We also propose solutions such as optimal processing methods based on the product’s application, specifications, and final destination. Please do not hesitate to contact us.

Facilities |

Cutting machine

|

|

| Equipment Name | Process | Maker | Workable Area | Quantity |

|---|---|---|---|---|

| Pipe & Sheet Fiber Laser Cutting Machine ENSIS3015RI | cutting | AMADA | 3070x1550 (3KW) | 1 |

| Fiber Laser Cutting Machine LC VALSTER3015AJ | cutting | AMADA | 3070x1550 (6KW) | 1 |

| Laser & Punch Combination Machine EML3610NT | cutting, tapping | AMADA | 2550×1525

Punch 3050×1525(4KW) | 1 |

| Laser Cutting Machine ML3015 eX-45CF-R | cutting | MITSUBISHI | 3050×1525(4.5KW) | 3 |

| Laser Cutting Machine LC-3015F1NT | cutting | AMADA | 3070×1550(3KW) | 1 |

| NC gas cutting | cutting | t65、1219×2538 | 1 | |

| NC Turret Punch Press | cutting | t6、1225×3040 | 8 | |

| Shearing Machine | cutting | t12、W2060 | 1 |

Bending process

|

| Equipment Name | Process | Maker | Workable Area | Quantity |

|---|---|---|---|---|

| Flat steel roller bender | t8、W75 | 1 | ||

| 3 Roller bender (small) | t2、W300 | 1 | ||

| 2 Roller bender | t3.2、W500 | 1 | ||

| 3 Roller bender | t6、W2000 | 2 | ||

| Press brake | bending | 300ton、W3000 | 1 | |

| Press brake | bending | 35ton、W1200 | 6 | |

| Press brake | bending | 80ton、W20001 | 1 | |

| NC press brake | bending | 35ton、W1200 | 1 | |

| NC press brake | bending | 100ton、W3000 | 2 | |

| Hydraulic press | straightening, pressing | 50t | 3 | |

| Hydraulic press | straightening, pressing | 100t | 3 | |

| Crank press | pressing | 35ton | 1 | |

| Crank press | pressing | 55ton | 3 | |

| Crank press | pressing | 60ton | 1 | |

| Crank press | pressing | 110ton | 1 | |

| Double crank press | pressing | 200ton | 1 |

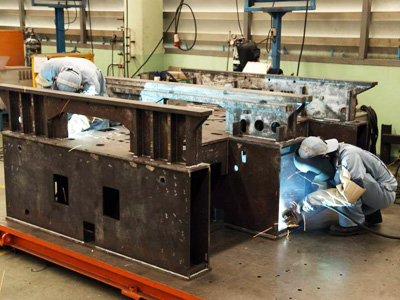

Welding

|

| Equipment Name | Process | Maker | Workable Area | Quantity |

|---|---|---|---|---|

| Soldering equipment | 1 | |||

| Silver brazing equipment | 1 | |||

| Stud welding | metal welding | 14000A | 2 | |

| Resistance welding machine | metal welding | 1500-29000A | 5 | |

| TIG welding robot | metal welding | 350A | 1 | |

| MIG welding robot | metal welding | 350A | 4 | |

| Tungsten inert gas welding machine | metal welding | 350A | 65 | |

| Metal active gas welding machine | metal welding | 350A | 65 | |

| Arc welding machine | metal welding | 300A | 25 |

Machining

|

|

| Equipment Name | Process | Maker | Workable Area | Quantity |

|---|---|---|---|---|

| Surface grinding machine | X300×Y600×Z200 | 1 | ||

| Vertical machining center | X700×Y1700×Z650 | 3 | ||

| Vertical machining center | X580×Y450×Z450 | 8 | ||

| Horizontal machining center | X1250×Y1000×Z850 | 2 | ||

| Radial drilling machine | 3 | |||

| Desktop drilling machine | 7 | |||

| Upright drilling machine | 7 | |||

| Milling machine | L800×W400 | 5 | ||

| Lathe (Large) | φ1000 | 1 | ||

| Bench lathe | φ20 | 2 | ||

| Lathe | φ250 | 6 | ||

| Numerical control lathe with automatic bar feeder | φ32 | 1 | ||

| Numerical control lathe (Large) | φ250×L800 | 1 | ||

| Numerical control lathe | φ200×L620 | 7 | ||

| Automatic material feeding band saw | φ300 | 4 | ||

| Band saw | parts cutting | AMADA | φ300 | 2 |

Surface treatment

|

|

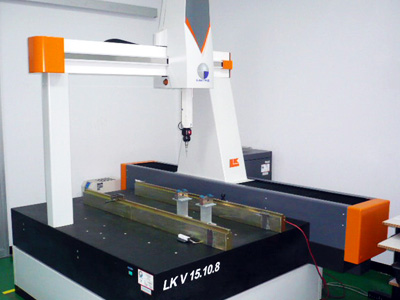

Inspection equipment

|

|

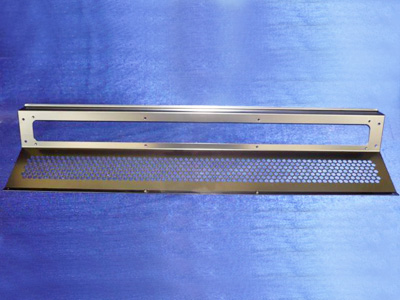

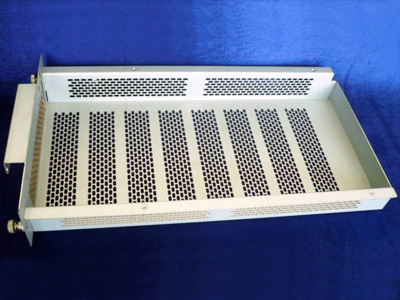

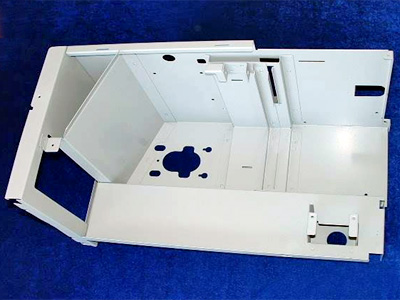

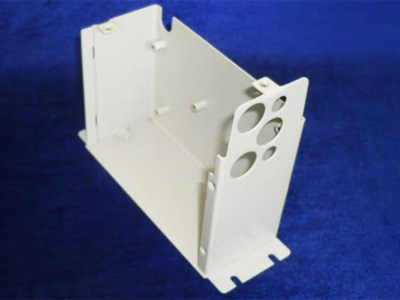

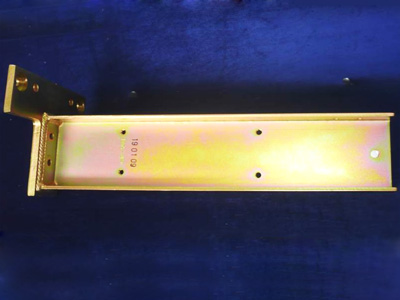

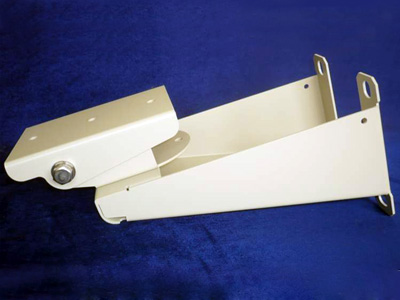

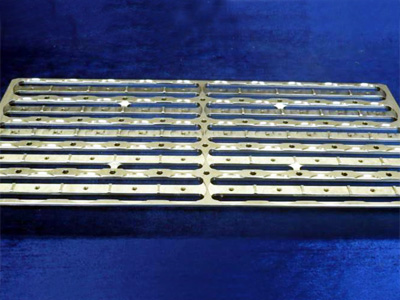

Examples of parts manufacturing and processing. |

Social infrastructure field |

|

New energy field |

|

Semiconductor field |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|