TENRYU SAW (THAILAND) CO., LTD.

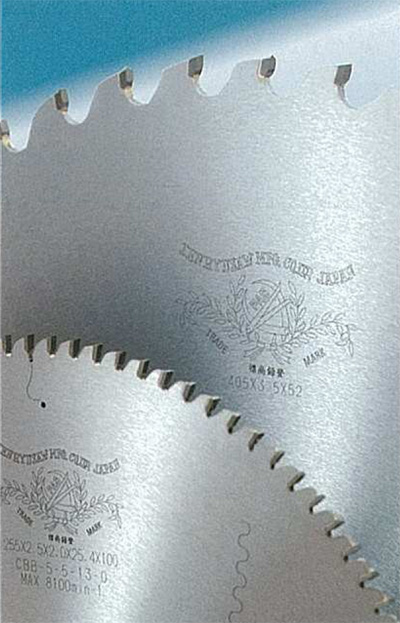

Manufacture and sale of Carbide tipped saw blades for industrial performance / Resharpening

Products |

Heavy / Light-duty Throwaway Type |

| Work material categories Iron, Stainless steel, Aluminum alloys, Copper alloys Work materials Bar steel, Stainless steel bar, Solid-drawn pipe Shapes Solid materials, Pipe, Other various shaped materials Dimensions

Tooth types Notched tooth with breaker Carbide tip materials Carbide P30, Cermet, PVD coating TiN, AlTiN, CrN Features Despite its thin kerf, this model boasts longevity, perpendicularity and smooth cut surface. |

For Heavy-duty Cutting |

| Work material categories Iron, Stainless steel Work materials Bar steel, Seamless steel pipe, Electrowelded pipe Work materials Shapes Bloom, Billet, Bar, Pipe Dimensions

Tooth types Triple Tip Grind, Notched Tooth Carbide tip materials Carbide M20・P30, PVD coating TiN, AlTiN, CrN Cutting parameters

| |||||||||||||||||||||

For Light-duty Cutting |

| Work material categories Iron, Stainless steel Work materials Solid-drawn steel pipe, Electrowelded pipe Work materials Shapes Pipe, Other various shaped materials Dimensions

Tooth types Triple Tip Grind, Notched Tooth, Chamfered Flat Tooth Carbide tip materials Carbide P30, Cermet Cutting parameters

|

Light-duty Cutting for Automobiles |

| Work material categories Iron, Stainless steel Work materials Door sash, Door molding, Exhaust pipe, etc. Shapes Roll formed material Dimensions

Tooth types Triple Tip Grind, Flat, Chamfered Flat Tooth Carbide tip materials Tungsten carbide P30, Cermet Cutting parameters

|

for Non-ferrous |

| Work material categories Aluminum, Copper, Brass, Other non-ferrous metals Work materials Cake, Billet, Extrusion, Molding, Continuous casting Shapes Solid materials, Pipe, Other various shaped materials, Plate Dimensions

Tooth types Triple Tip Grind, Flat, Chamfered Flat, Breaker Tooth Carbide tip materials Carbide K10 – K30 Features Considering high-speed-cutting, LAQ type is available which is effective in reducing vibration

Cutting parameters

|

Resharpening* Maximum diameter 860mm × Minimum pitch 6mm [For more information, please contact us.] |

Our commitment to cutting extends into resharpeningAnother of our important themes is to maintain the performance of your saw blade at its very best. Maintaining the performance of a new product is not the only purpose of resharpening. We inspect the blade in detail after use, and we analyze the cutting condition during use. Based on these results, we propose the most economical form of processing. We believe that the best possible resharpening service is that which provides a way of maintaining a superior cost performance. |

|