Carburizing process to improve the wear resistance of metal surfaces

The demand for heat treatment is increasing in order to make metal parts stronger and longer-lasting.

DOWA's technology for heat treatment of metal parts for various purposes includes carburizing, carburizing nitriding, and hard coating treatment.

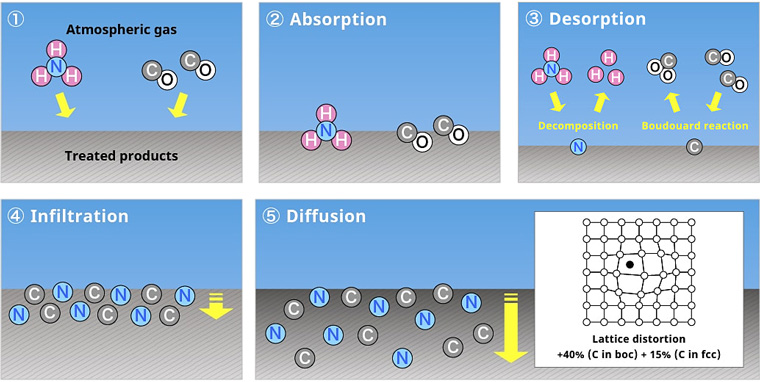

Carbonitriding mechanism |

Hardenability is enhanced (quenching distortion is reduced) by bringing nitrogen from ammonia gas (NH3) on the surface and allowing it to infiltrate inside together with carbon.

Aim of carburizing and quenching |

|

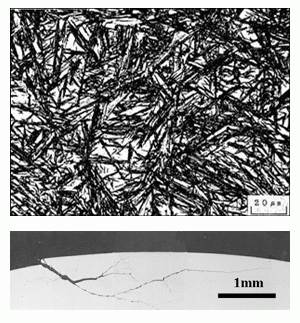

When metal fatigue occurs, cracks occur and propagate on the surface that receives the maximum shear stress, leading to fracture. Therefore, the mechanical properties of the metal surface layer play a vital role. The purpose of carburizing and quenching is to increase the hardness and strength by quenching with a surface layer of 0.7% to 0.9% C and transforming the structure of the material into martensite. As a result, durability and wear resistance are improved. |

|

Examples of application for Carburizing |

|

<Surface modification> We propose process technology accumulated over many years according to the customer's product design. |