Quality Control System / Dealing with environment

[ Quality Control System ] Providing the same level of quality as Japan

|

|

We provide "the same level of quality as Japan" by using the heat treatment technology cultivated in Japan. We promise high quality, such as thorough control of the manufacturing process that supports reliability and thorough control of traceability.

≪Quality policy≫

■ Compliance with work rules

■ Investigate the true cause of poor quality

■ Improving the ability of inspectors

■ Produce with reliable equipment and jigs

■ Foster employees with high skill levels

|

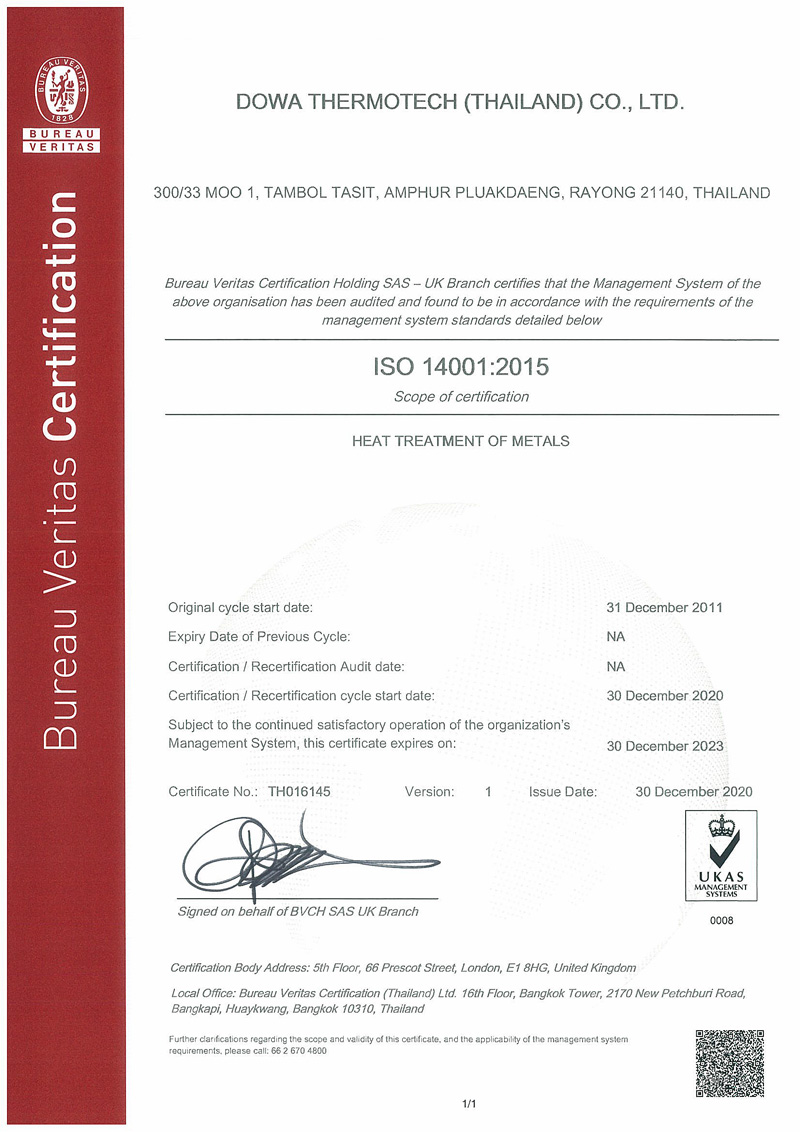

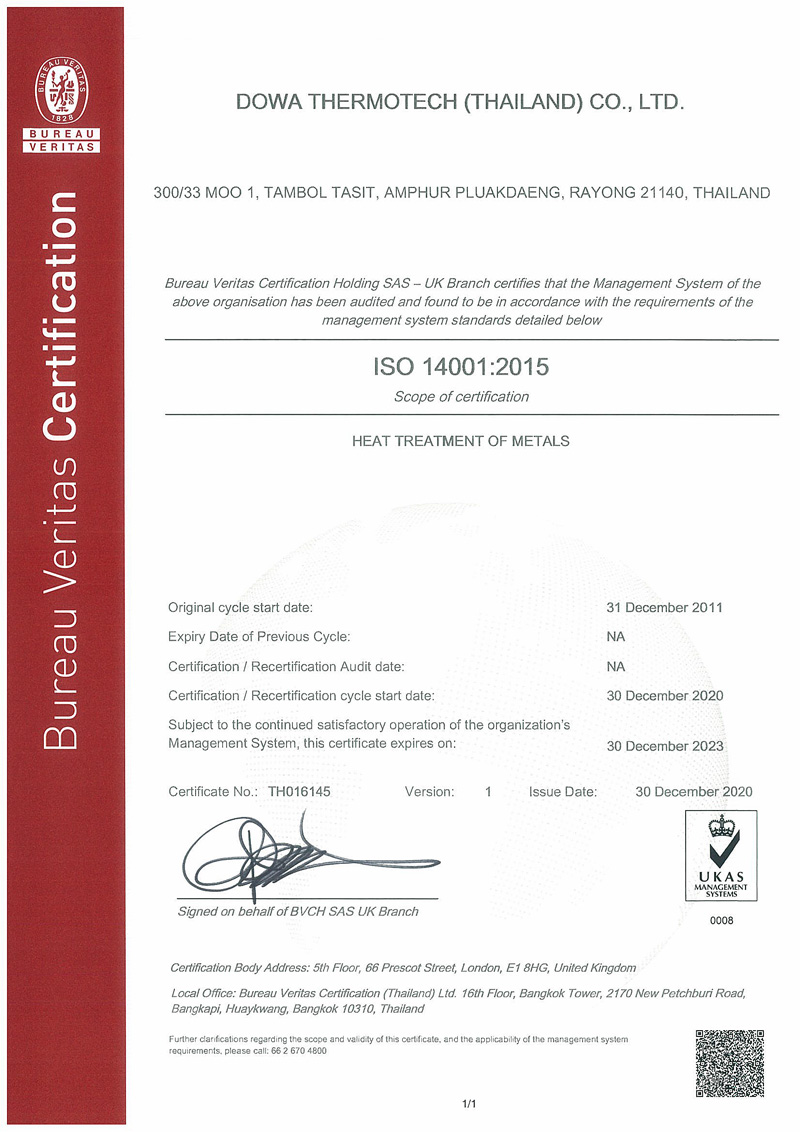

ISO14001:2015

|

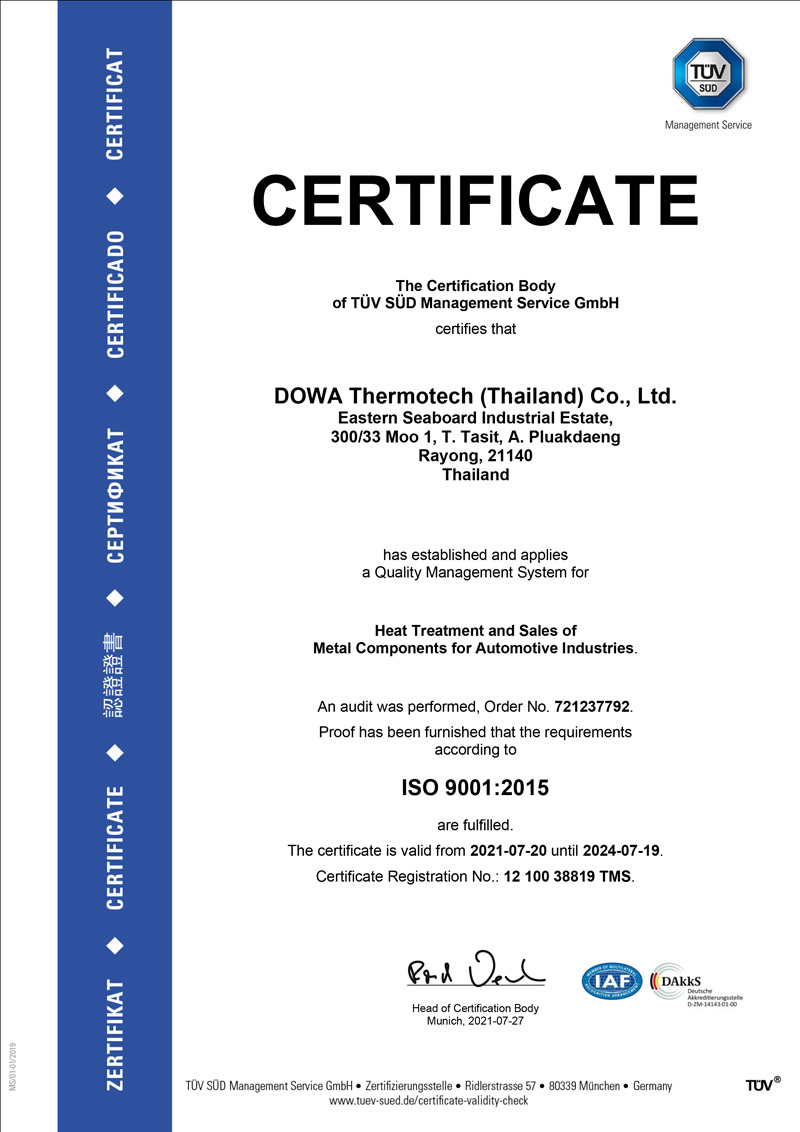

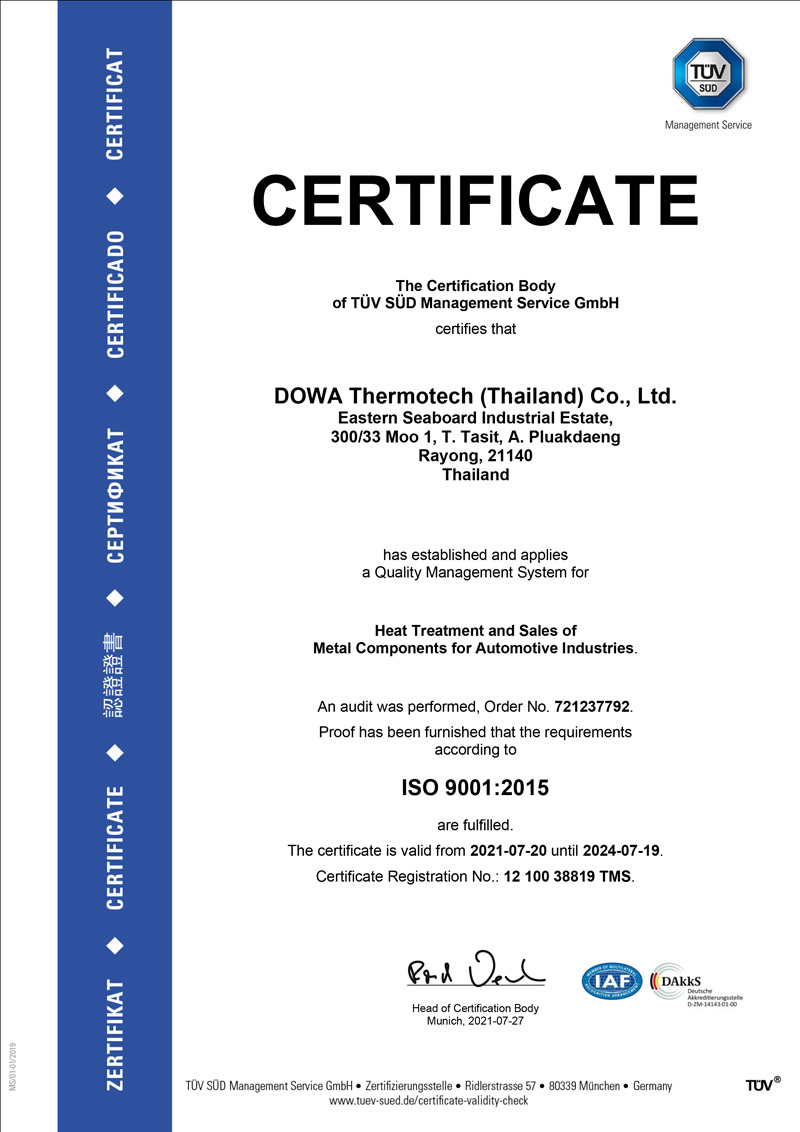

ISO9001:2015

|

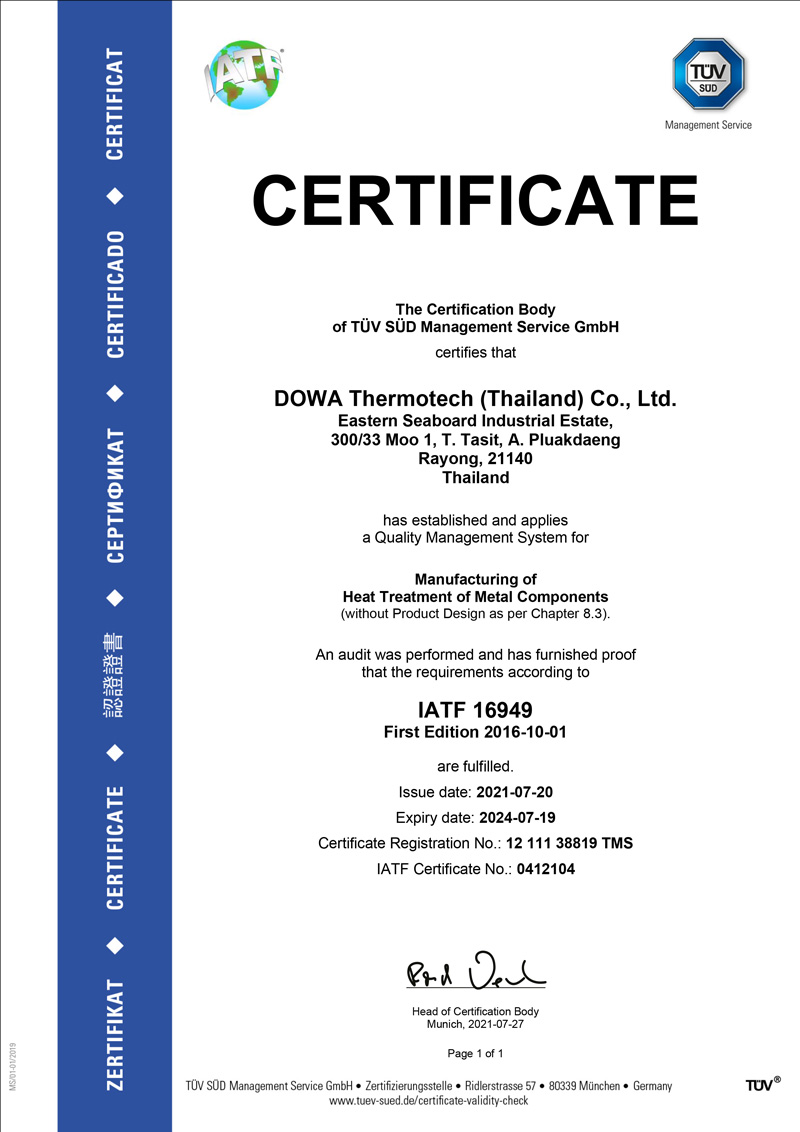

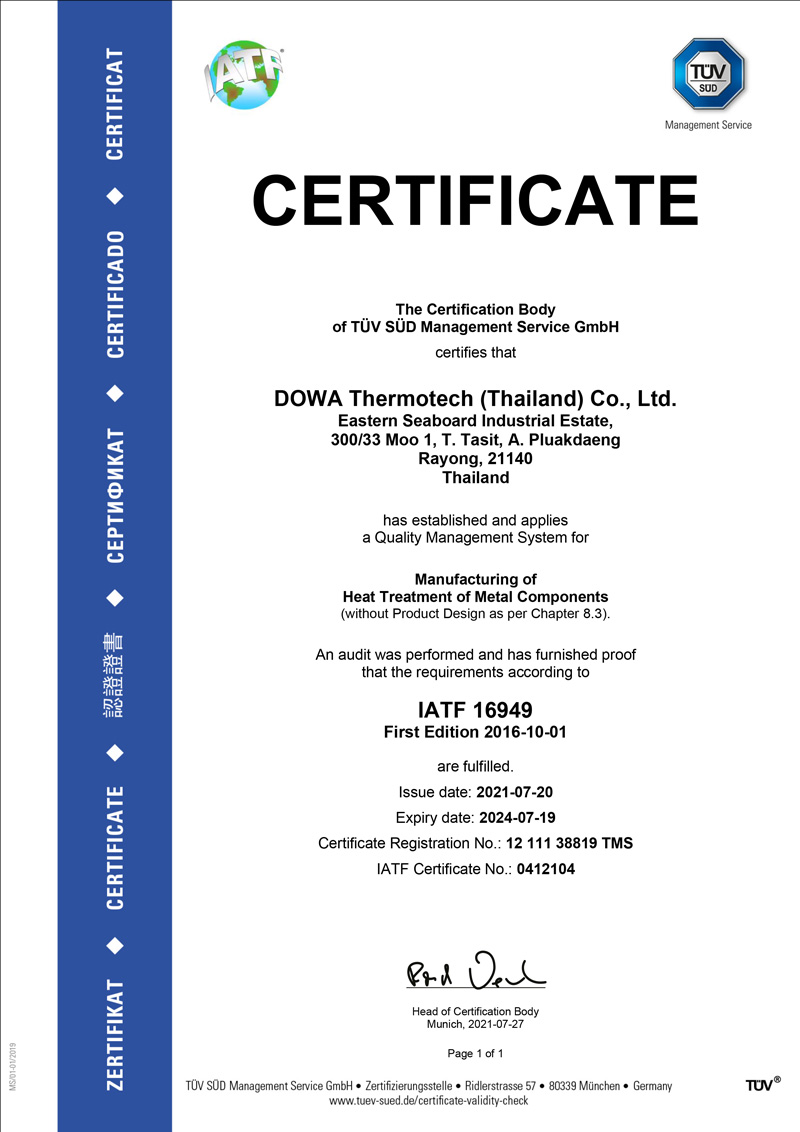

IATF16949:2016

|

►Inspection equipment that supports high quality

Measuring equipment suitable for measuring various heat-treated parts. Various hardness meters such as Digital Rockwell and Micro Vickers, and metallurgical microscopes. In addition, various dimensional measuring instruments, sample preparation equipment, etc.

|

Micro Vickers hardness tester

|

Rockwell hardness tester

|

Metallurgical microscope

|

[ Efforts for the environment ] The future environment of the earth

|

|

The DOWA Thermotech Group conducts environmental activities based on our own environmental policy in our business activities, and actively promotes the reduction of environmental load.3

≪Environmental policy≫

■ Strictly comply with environmental laws and related requirements related to organizational environmental issues

■ Preventing or reducing pollution released into the environment from the production process And dispose of the waste in an appropriate way.

■ Minimize and effectively use resources and energy

■ Prevent accidents and disasters.

■ Continuous improvement and improvement to minimize the impact on the environment

|

|

►Improved fuel economy

By increasing the strength of steel, parts can be made smaller and lighter. In addition, surface modification is carried out to reduce frictional resistance and improve fuel efficiency, thereby contributing to global environment-friendly manufacturing.

►Energy saving

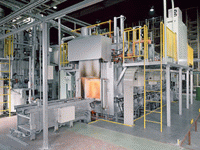

In the industrial furnace business, we are also focusing on new technology development. We have delivered small continuous furnaces that have tripled productivity in the same space as conventional batch furnaces.

We are developing new types of furnaces such as the S-TKM series, which have a low environmental impact and save energy.