|

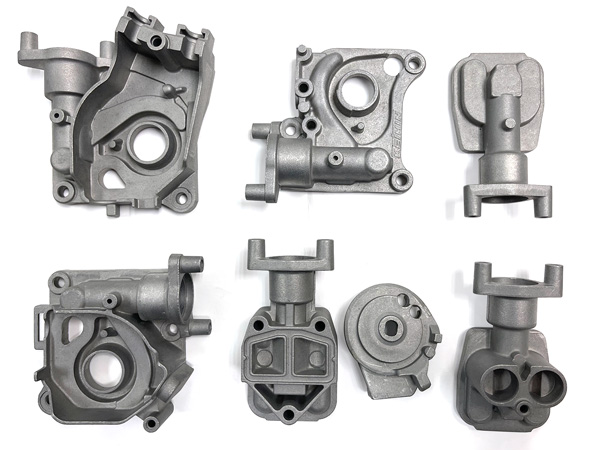

Motorcycle Throttle

Body Components

A core component that controls the volume of air intake in engine air management systems. An area where precision die-casting technology demonstrates its strength.

"The heart that controls the engine’s breathing."

|

|

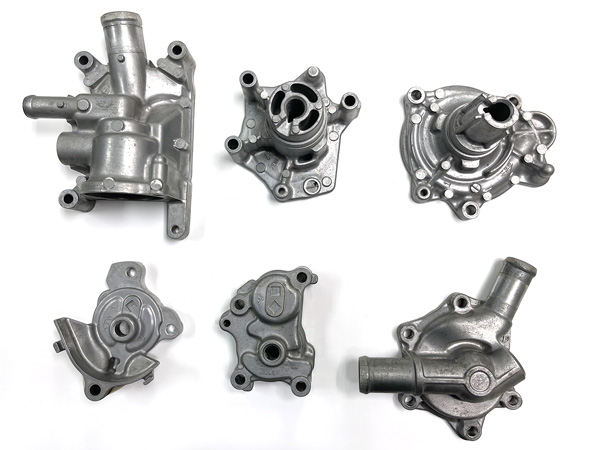

Motorcycle Water Pump /

Oil Pump Components

Critical components responsible for engine cooling and lubrication. Compact, lightweight, and designed with excellent wear and heat resistance.

An essential part that protects the “heart” of a motorcycle — the engine — where precision die-casting technology is fully utilized.

|