Optimal wear protection solutions for your punching and forming tools

In production, stamping and forming tools are exposed to extreme forces and, consequently, subject to wear. You can minimise the wear of your tools, however, with BALINIT® hard coatings and BALITHERM® plasma-diffusion treatment by Oerlikon Balzers.

As a global technology leader in surface solutions, we can offer you significant advantages with our coating solutions and diffusion processes that will boost the efficiency, cost-effectiveness, and ecological soundness of your applications.

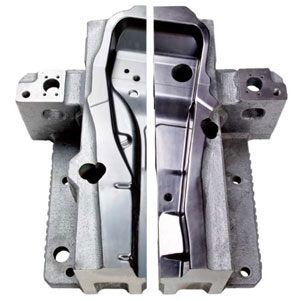

BALINIT FORMERA

The coating solution for Advanced High Strength Steel forming applications

developed to meet the challenges of AHSS forming Emissions legislation and increased passenger safety, require lighter, stronger vehicles. To fulfil these requirements the % use of Advanced High Strength Steel (AHSS) material and the MPa strength of these parts is increasing with every new model. Tools forming AHSS parts require even stronger surface solutions to ensure high quality and productivity in these demanding applications.

BALINIT LUMENA

Fulfil the toughnest requirements in forming

BALINIT® LUMENA. The TiAlN coating with minimised residual stress significantly reduces abrasive wear in forming tools. The cold welding problem is largely deminished by the chemical composition of the coating. Cleaning intervals are extended and at the same time, product quality is improved.

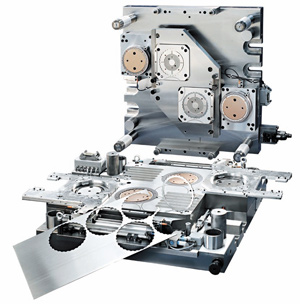

BALINIT ALCRONA PRO

Punching and forming at top level

Better coating properties for many applications, extreme machanical and thermal stress impose considerable problem on tools with the new AlCrN coating. BALINIT® ALCRONA PRO is ideally suited for operation such as Piercing blanking, Fine blanking, Extrusion, Sheet metal forming, forging and etc.