Nihon Shinkan (Thailand) Co., Ltd.

Japanese high-precision drawn aluminum pipe & bar manufacturer in Thailand

Production Line, Technical Information

Production Line |

click on each process. |

|

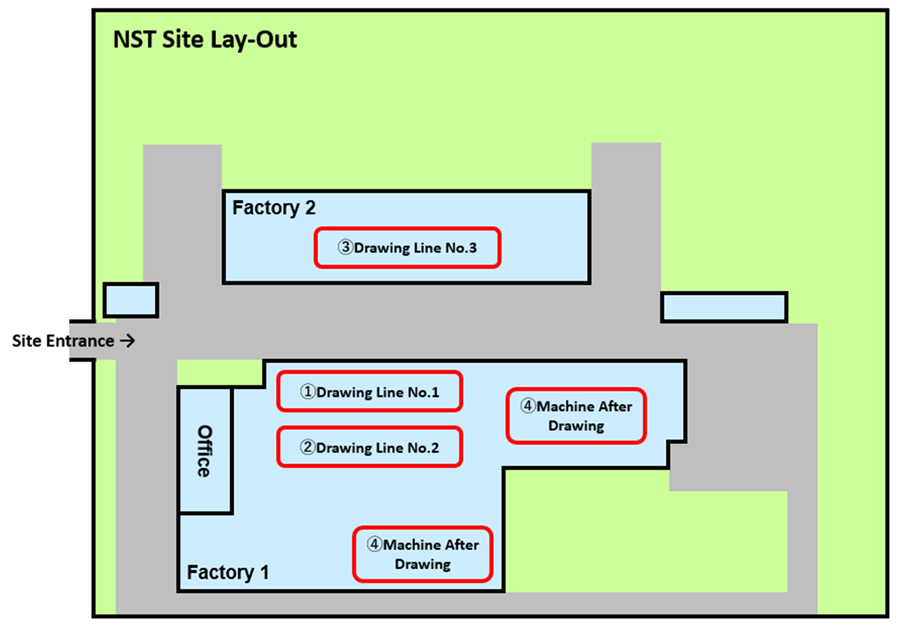

① Drawing Line No.1 | Factory 1 |

Capability Pipe Φ11~40 | Products Hi-Precision Drawing Pipe | Use for OA OPC Drum, Developing Sleeve |

Process | Machine | Detail |

Pointing | Pointing (Middle) | Capability: Material Size Φ45 |

▼ | ||

Drawing | Drawing No.1 | Capability: Φ11~40 |

Drawing No.2 | Capability: Φ11~40 | |

▼ | ||

Reeling | Reeling No.1 | Capability: Φ20~40 |

Reeling No.2 | Capability: Φ11~20 | |

Reeling No.6 | Capability: Φ11~20 for Developing Sleeve | |

▼ | ||

Cutting | Cutting No.1 | Capability: Φ11~40 L50~3000 |

Cutting No.2 | Capability: Φ11~40 L100~1500 | |

▼ | ||

Washing | Washing No.1 | for Short Length:to L500 |

▼ | ||

Heating | Heat Treatment No.1 | Temperture: Max400℃ Max Length: L3000 |

▼ | ||

Complete | to Process after Drawing | after Drawing to Other Table |

② Drawing Line No.2 | Factory 1 |

Capability Bar Φ12~30 | Products Hi-Precision Drawing Circle Bar, Hexagon Bar | Use for Material for Hi-Precision Lathe Turning |

Process | Machine | Detail |

Pointing | Pointing (Bar) | Capability: Material Size Φ40 |

▼ | ||

Drawing | Drawing No.3 | Capability: Φ12~30 |

▼ | ||

Reeling | Reeling No.3 | Capability: Φ12~30 |

Reeling No.5 | Reeeling for Hexagon Bar | |

▼ | ||

Cutting | Cutting No.3 | Capability: Φ11~60 L100~4000 |

▼ | ||

Washing | Washing No.4 | for Long Length:to L4000 |

▼ | ||

Heating | Heat Treatment No.1 | Temperture: Max400℃ Max Length: L3000 |

▼ | ||

Complete | Inspection & Packing | Package: Carton Box, Steel Rack etc. |

③ Drawing Line No.3 | Factory 2 |

Capability Pipe Φ40~120, Bar Φ40~80 | Products Hi-Precision Drawing Pipe (Big Size) | Use for Material for Automotive & Motorcycle |

Process | Machine | Detail |

Pointing | Pointing (Big) | Capability: Material Size Φ120 |

▼ | ||

Drawing | Drawing No.4 | Capability: Φ40~120 Biggest in ASEAN |

Drawing No.5 | Capability: Φ40~100 | |

▼ | ||

Reeling |

|

|

▼ | ||

Cutting | Cutting No.4 | Capability: Φ10~100 L50~3000 |

▼ | ||

Washing | Washing No.6 | for Short Length:to L500 |

▼ | ||

Heating | Heat Treatment No.2 | Temperture: Max250℃ Max Length: L4000 |

▼ | ||

Complete | Inspection & Packing | Package: Carton Box, Steel Rack etc. |

④ Machine after Drawing | Factory 1 |

Capability Pipe Φ10~35 | Method Both Sides Lathing, Centerless Grinding, Assembly | Use for Developing Sleeve, Roller |

Process | Machine | Detail |

Inspection | Inspection

| Inspection:Auto 2Pcs Manual 1Pcs |

Rework:Automatic 2Pcs | ||

Lathing | Both Side Lathing

| Tool Spin Type: 2Pcs |

Work Spin Type:3Pcs | ||

Work Spin Type:2Pcs Hi-Precision | ||

Grinding | Centerless Grinding

| Micron: MD-600Ⅲ |

Outside Spec±3μm Run-Out:8μm/L300 | ||

Grooving | Grooving

| Grooving to Outside Pipe for OA Developing Sleeve |

Grooving Depth Spec ±7.5μm | ||

Assembly | Insert Assembly | Insert Assy Flange of Steel・SUS・AL |

Run-Out(Sleeve): 15μm/L300 | ||

Run-Out(Roller): 50μm/L300 | ||

Complete | Inspection & Packing | Package: Carton Box, Plastic Box etc. |

⑤ Technical Information |

| Chamfering to Both SidesChamfering Both Sides by Machine Type of "Tool Spin" or "Work Spin".

|

| Centerless Grinding to Outside PipeGrinding by Spining Wheel, Improves Roundness and Bending(Run-Out).

|

| Grooving Process to Outside PipeGroove Cutting to Longitudinal Direction of Outside Pipe.

|

| Assembly Aluminum PartsInsert Assembly Flange of Steel,SUS,AL to Inside Pipe, Roller.

|

| Punching ProcessPunch the Holes in the Pipe as Order.

|

| Bending ProcessBend the pipe into the specified shape.

|