KAGA (THAILAND) CO., LTD.

Specialist Company about cold forging stamping & precision progressing stamping & Heat treatment by hydrogen gas furnace

|

Precision Drawing progressing stamping ,

|

|

Cold forging transfer stampingCreate high precision and complex shape forming by net-shaping technology ( maximize production yield of material). |

Precision Drawing progressing stampingHigh accuracy Shape reproducibility and stability on mass production with high quality by our stamping technology. |

Annealing treatment by Continuous Hydrogen gas FurnaceContinuous furnace is shorter treatment time than Batch Furnace, Also Temperature of furnace is controllable to be reached by 1,200 cent degree for adaptation of various material. |

|

◆Precision deep drawing Progressing stamping (from designing stamping die to completed products) ◆Progressing Stamping ◆Cold forging transfer stamping |

|

High accuracy Shape reproducibility and stability on mass production with high quality by our stamping technology.

|

for Factory Automation |

We are promoting automation in collaboration with the Quality Assurance Department and the Production Engineering Department. We have made further quality improvement with insourcing for production of inspection equipment and jigs.

|

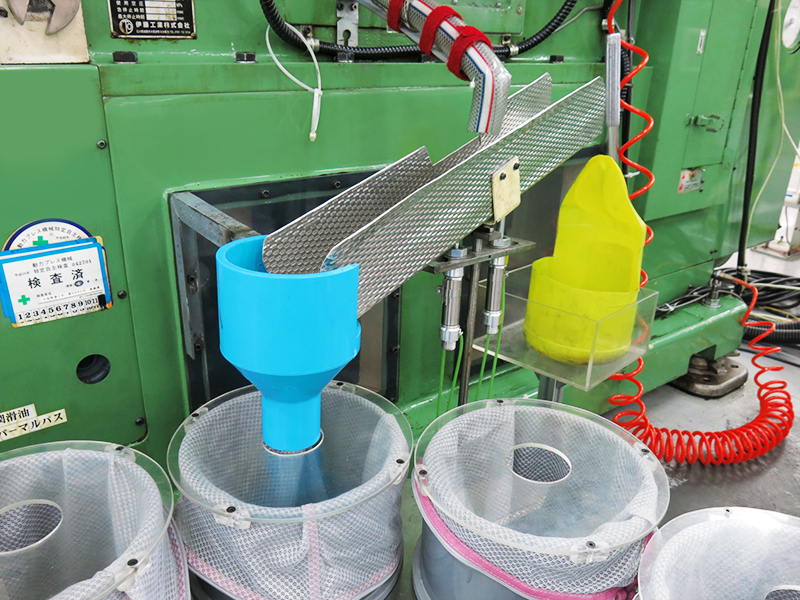

We have manufactured an automatic rotary box changer by ourselves. We can specify the number of products in each boxes. When the counter reach to specific the number of products. it automatically turns and replaces the box. The shooter is equipped with an acrylic plate and a net to prevent the product from falling off and contamination. |

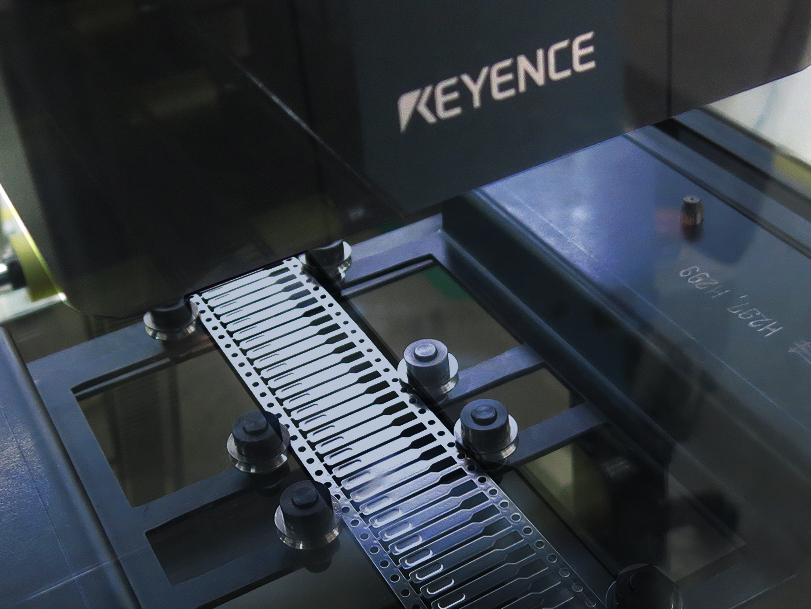

We have introduced automatic inspection equipment to perform high-speed image processing (line camera) judgment for products with large volumes and demanding. This equipment unit is manufactured insourcing and is used for general purposes. |