Click each logo to see details.

FA BusinessAsyril SA |

|

Flexible Feeding Systems |

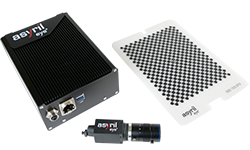

Experts in Flexible Feeding Systems

Asyril develops, produces and markets high performance flexible feeding systems for parts and components from <0.1 up to 150 mm in size. Our innovative 3-axis vibration technology can handle bulk parts of any geometry and allows for extremely gentle part feeding.

► Asycube Series - 3-Axis Vibration Robotic Parts Feeder |

|

SmartSightIntelligent visual part detection system for Asycube flexible feeders |

EYE+Smart Control Systems for Asycube flexible feeders |

Asyfeed Pocket ModuleIntegrated Flexible Feeding Module |

FA BusinessUniversal Robots |

|

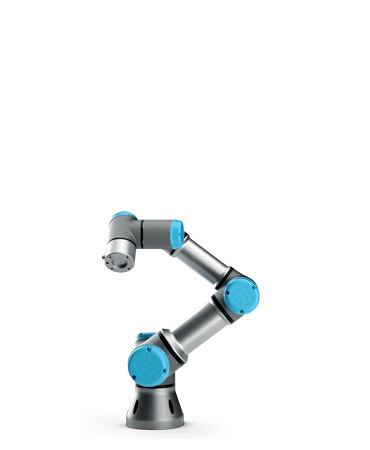

Robotic Automation with the World’s #1 Cobot |

Address your labor needs, increase your productivity and become more competitive

Cobots from Universal Robots give manufacturers access to all the benefits of advanced robotic automation, without the extra costs associated with traditional robots: difficult programming, long set-up, and shielded work cells. This makes automation affordable even for small-batch production runs and mixed product assembly.

Universal Robots has sold more than 50,000 collaborative robots which are used in several thousand production environments every day around the world |

Products |

New!! UR16e ROBOT Introduction Video

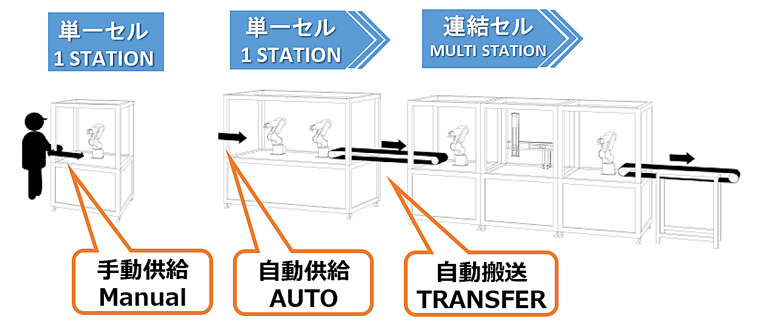

FA BusinessYamaha Motor Co., Ltd. × NIC Autotec, Inc. |

|

ROBOT KIT (with Aluminium frame) |

► Free design , Free Layout |

► Application *You can choose other type robot. |