Yamaha Motor Co., Ltd. |

|

Only Yamaha can provide a unified lineup from miniature actuators to articulates robots.

We provide the best solution for a wide range of automation.

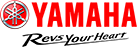

Linear Conveyor Module LCMR200 |

Yamaha’s answer to Next Generation of Production Line design

Repeatability:±5μm Maximum speed*:2,500mm/sec

* When the conveying weight exceeds 10 kg, it will drop to 1,000 mm/sec according to the weight.

Feature

Advanced linear conveyor module with high speed transport.

Advanced linear conveyor module with high speed transport.

50% reduction in tact time (compared to the conventional conveyor)

Improve cycle time and reduce line floor space. Increase productivity and cost performance.

Reduction of Tact Time Reduction of Tact Time |

Flexibility in line design Flexibility in line design |

Easy maintenance Easy maintenance |

Space saving design Space saving design |

Improved Productivity Improved Productivity |

Reduces line design time Reduces line design time |

Low operation cost Low operation cost |

Durability Durability |

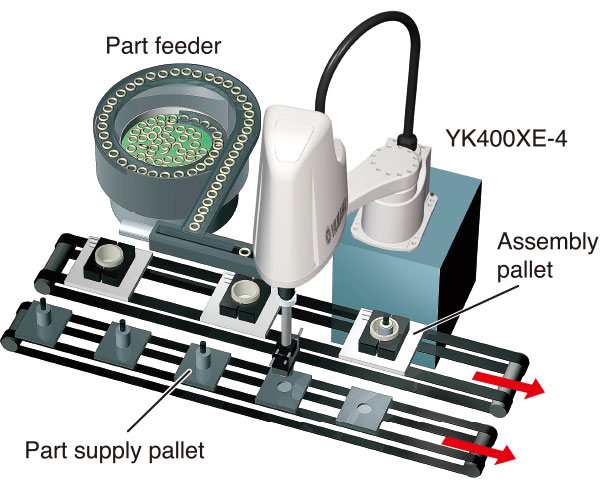

Clean SCARA Robot YK-XEC Type |

Ideal for automation work in clean rooms!

Ideal for productivity improvement and labor saving in semiconductors, hard disk drives, food products, medical equipment, etc.

The clean type "YK-XEC" series, ideal for automation work in clean rooms, has been added to the "YK-XE" series SCARA robots, which combine high operational performance and cost performance. Main specifications maintain the same performance as "YK-XE".

Balancing ISO CLASS 4 cleanliness and low cost

Balancing ISO CLASS 4 cleanliness and low cost

We have achieved affordability even with clean models. Arm length options are available, mirroring the YK-XE series with 4models to choose from.

Degree of cleanliness:ISO CLASS 4(ISO14644-1)

Arm length:400 to 710mm Maximum payload:4 to 10kg

Improvement of productivity by high-speed operation

Improvement of productivity by high-speed operation

By reviewing the arm structure, the vibration is reduced and the motion is optimized to shorten the standard cycle time. High-speed, less-vibration, and agile operation contributes to improvement of the productivity.

Large type SCARA robot YK1200XG |

Suitable for assembly and transfer of large objects or heavy objects.

High payload × High speed achieved

Maximum payload:50kg

The standard cycle time:0.92sec * 40kg workpiece payload

Feature

Completely beltless structure

Completely beltless structure

A totally beltless structure was achieved by using a ZR axis direct coupling structure. This direct drive structure drastically reduces wasted motion. It also maintains high accuracy over a long period of time.

Long-term maintenance-free is achieved

Long-term maintenance-free is achieved

It ensure maintenance-free usage for extended periods with no worries about belt breakage, stretching or deterioration with age.

The main body weight is reduced approx. 25% (compared to the conventional product)

The main body weight is reduced approx. 25% (compared to the conventional product)

While the base is made of iron to maintain rigidity, the body is made of aluminum, taking advantage of the aluminum extrusion technology Yamaha has accumulated over many years, and making it approximately 30 kg lighter than our long-selling model “YK1200X”.

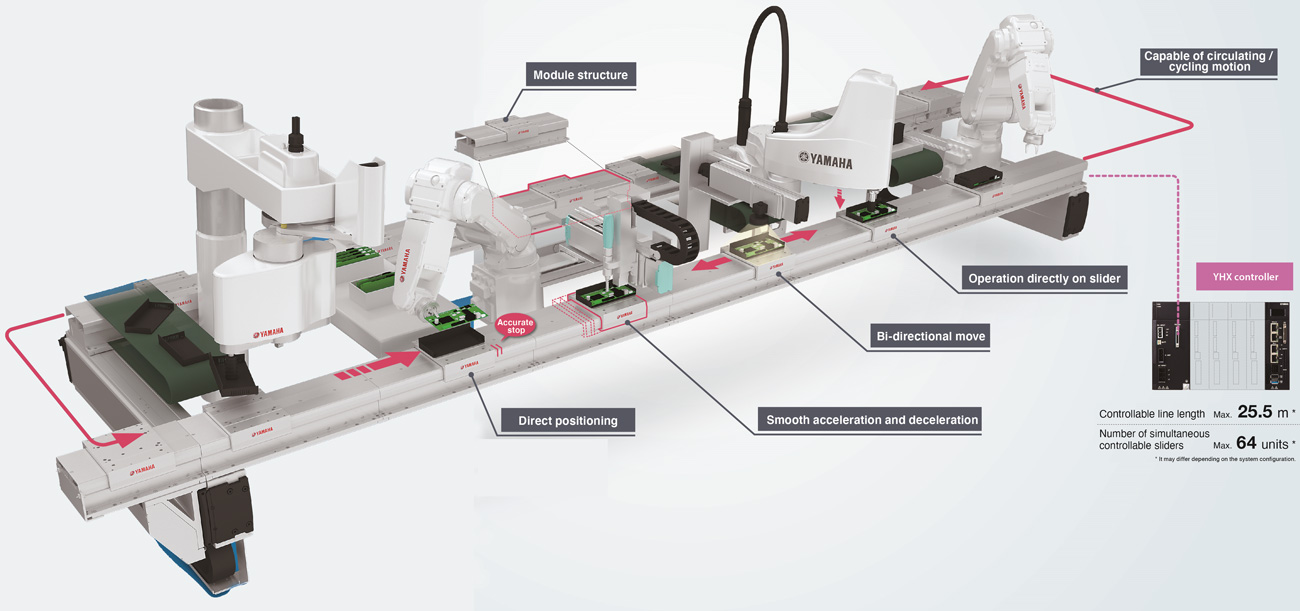

Dedicated for RCX340 Speed Monitoring Unit RCX3-SMU |

Made it possible to balance

Safety x Maintaining productivity

In recent years, safety awareness has been on the rise, particularly in Europe, and ensuring safety has become an increasingly important perspective.

The RCX3-SMU is the first Yamaha robot-related product that has acquired the functional safety certification.

Yamaha Robot Controller "RCX340" can be connected to the dedicated optional unit "RCX3-SMU" to support functional safety.

Feature

Protective stop

Protective stop

Unlike an emergency stop, which stops the entire device, a protective stop allows you to stop only a single robot. This makes equipment recovery easier and leads to improved production efficiency.

Third-party certification by TÜV SÜD

Third-party certification by TÜV SÜD

● Safety Standards for Industrial Robots ISO10218-1:2011

● Standards for Functional Safety of Machinery IEC 62061:2021

● Functional Safety Standards EN ISO 13849-1:2015

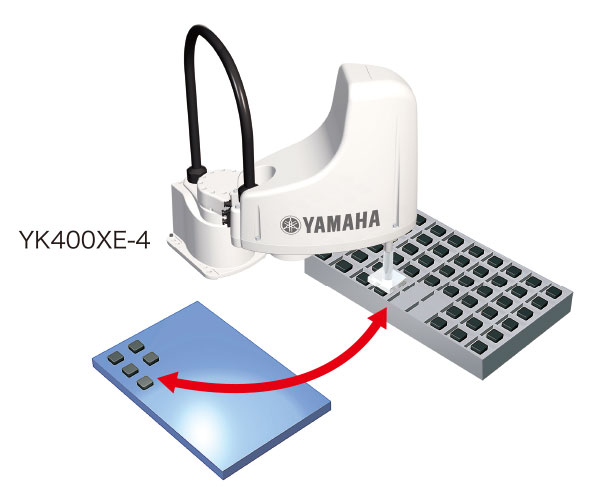

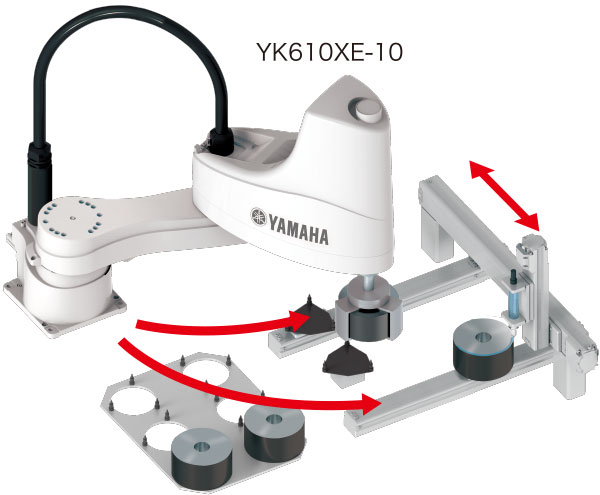

Low Cost High Performance SCARA Robot YK-XE |

Efficiency In Production

For improved efficiency and reliability in production at affordable price

Arm length:400mm to 710mm Maximum payload:4kg to 10kg

Feature

Optimal for transfer and assembly of automotive parts

Optimal for transfer and assembly of automotive parts

Maximum payload:10kg * For YK610XE-10 and YK710XE-10

Improvement of productivity by high-speed operation

Improvement of productivity by high-speed operation

By reviewing the arm structure, the vibration is reduced and the motion is optimized to shorten the standard cycle time. High-speed, less-vibration, and agile operation contributes to improvement of the productivity.

For a wide variety of applications Maximum payload 4kg to 10kg

For a wide variety of applications Maximum payload 4kg to 10kg

The models support a wide variety of fields such as assembly work that requires a high precision or food sorting work that requires a high-speed operation. As the maximum payload is 10 kg, heavy workpieces such as automotive parts can also be supported.

|

|

|

|

|

Affordable Price and Improved Performance

Affordable Price and Improved Performance

Both the high operation performance and affordable price are achieved. Production equipment with high cost performance can be constructed.

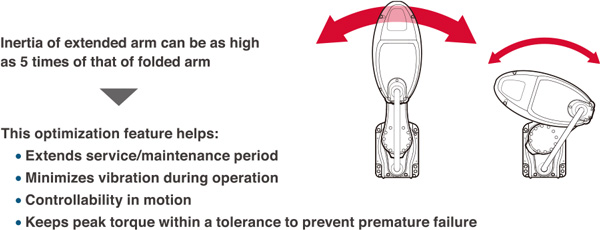

In Yamaha YK-XE series Acceleration/Deceleration is optimized automatically

In Yamaha YK-XE series Acceleration/Deceleration is optimized automatically

The optimal acceleration and deceleration are automatically selected from the arm posture at the time of operation start and the arm posture at the time of operation end. The motor peak torque or the tolerable peak torque of the speed reducer is not exceeded by inputting only three parameters*. The full power of the motor is always output to maintain the high acceleration/deceleration.

* Payload, R-axis moment of inertia, and offset amount of R-axis moment of inertia

Drop-In upgrade by common platform design

Drop-In upgrade by common platform design

The installation position of the YK400XE-4 is fully compatible with that of the conventional model YK400XR. This ensures easy replacement work.

Easier operation in combination with the RCX340 controller

Easier operation in combination with the RCX340 controller

RCX340 comprehensive controller brings out maximum potential of YK400XE robot system. Optional integrated vision system “iVY2” provides simplified image processing. Choice of PC Programming Software or Teaching Pendant available.

⇒Other SCARA Robot Information

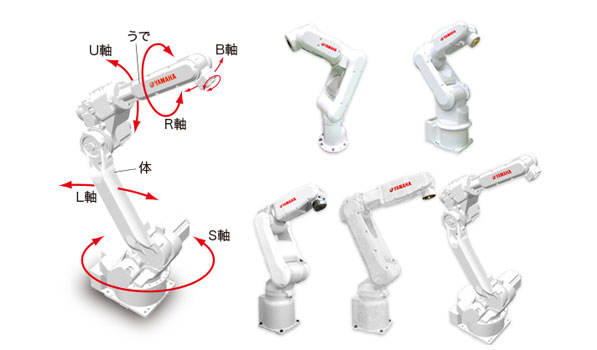

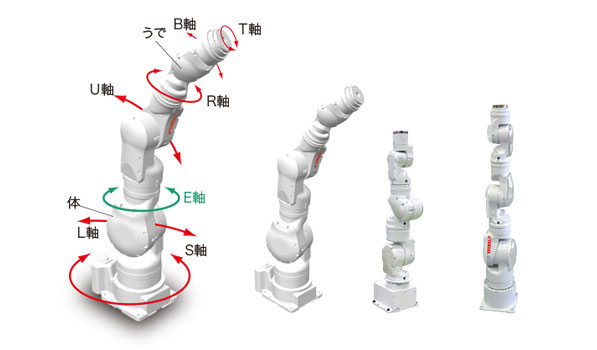

Articulated robots YA Series 6 axes / 7 axes |

Ideal for constructing compact cells, for moving or assembling small parts, and for performing inspection processes.

The articulated robots 'YA series' pursue high speed and space saving to contribute to production facilities for improved productivity and downsizing.

Combined with a running axis, the YA series robots make the transport between processes more efficient. Best suitable for building up a compact process cell and processes of transporting small parts, assembly, and inspection.

|

YA Series 6 axes |

YA Series 7 axes |

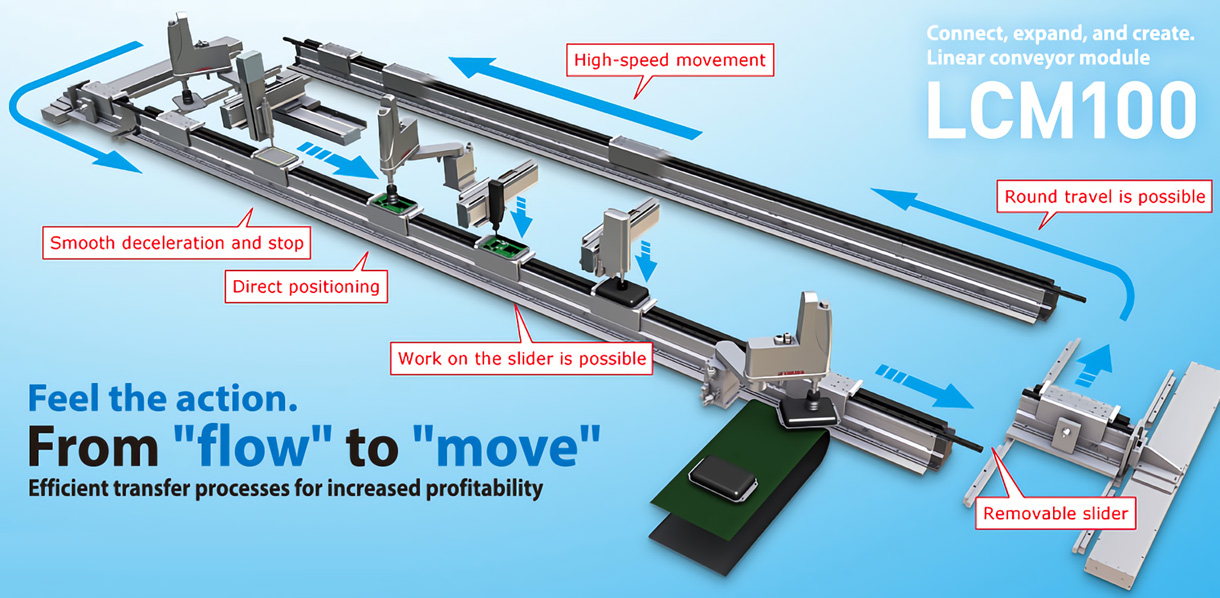

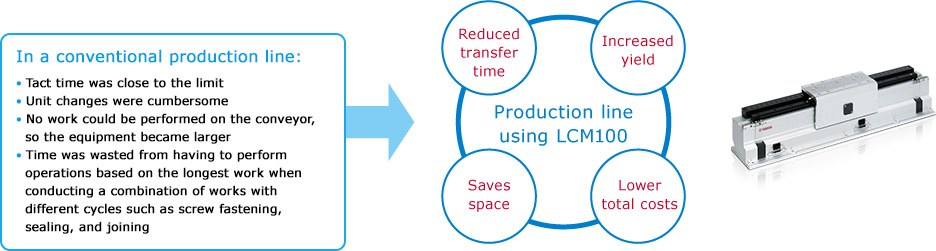

Liner Conveyor Modules LCM100 |

Next generation linear conveyor LCM100 supersedes belt conveyors and roller conveyors.

Improve takt time Improve takt time |

Increased throughput Increased throughput |

Excellent maintainability Excellent maintainability |

Reduced transport line space Reduced transport line space |

Flexible line configurations Flexible line configurations |

Shorter start-up time Shorter start-up time |

Lower running costs Lower running costs |

Long service life Long service life |

|

高スループット組立ライン |

Features --- Linear conveyor modules |

|

YAMAHA PAS |

Examples of Transfer Applications |

Feature

To all customers who have concerns regarding your production line

The issues facing the manufacturing industry continue to increase each year: shortened lead time, reduced cost, increased product quality, support for small production lots of diverse types, and reduced installation space.At a single stroke, the LCM100 solves these issues by fundamentally overturning existing concepts of transport between manufacturing processes. Why not implement the next generation of production line with us?

Others |

|

Stepping motor single axis robotTRANSERVO series have exellent characteristics of both the stepping motor and servomoter. |

Single axis robotsA wide variety of single-axis robots, FLIP-X series, from super-compact size to super-long stroke. |

Linear motor single axis robotsDelivers superb performance during long distance conveyance! |

|

Cartesian robotsOffering a full lineup of Cartesian robots to support a wide array of applications. |

ControllersHigh-performance controllers that support the YAMAHA industrial robots. |

Pick & place robotsIdeal for high-speed pick & place tasks using small parts. |

|

Clean robotsCleanroom model robots. |

Robot Vision SystemiVY system makes it possible to propose new production lines that do not require workpiece positioning and teaching. |

Electric grippersAn electric gripper achieving the highly accurate gripping force, position, and speed control. |

|

Base MachineThe base machine which combines advanced mounter technology in module size with easy to use robot functionality. |

CableDimensional diagrams and model numbers of the robot cables, cable terminals, and connectors are available. |

|