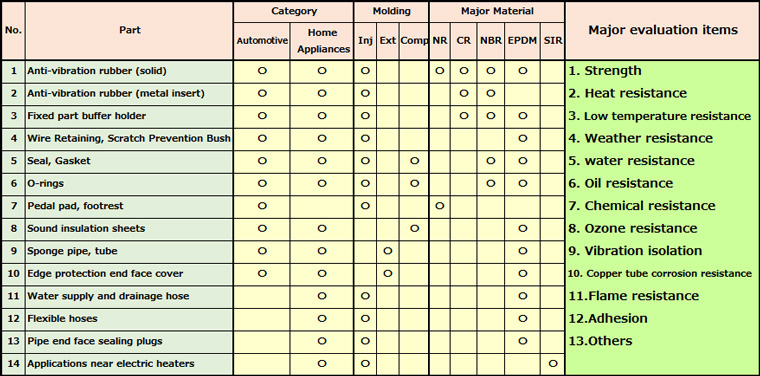

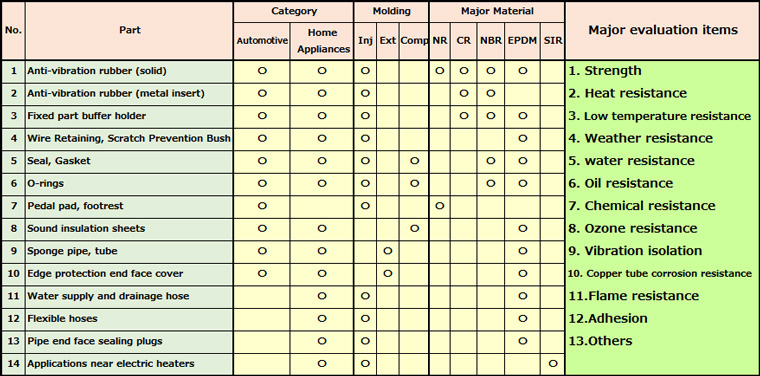

Main Material,Parts,Evaluation Sample

|

|

NR

Natural rubber

|

CR

Chloroprene rubber

|

SBR

Styrene-butadiene rubber

|

NBR

Nitril-butadiene rubber

|

|

EPDM

Ethylene-propylene diene rubber

|

IIR

Butyl rubber

|

SIR

Silicone rubber

|

ACM

Acrylic rubber

|

|

Material Preparation (Mixing,Cutting)

|

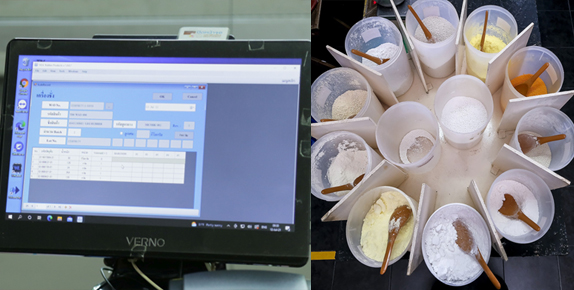

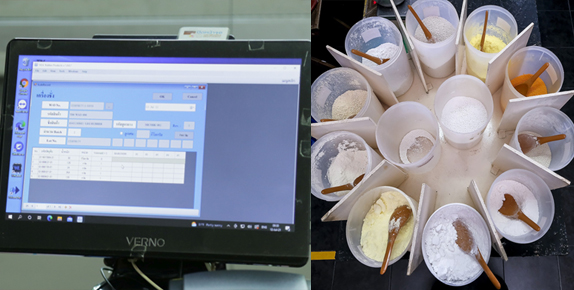

~ Chemical Blending ~

|

Cross-linking chemicals, vulcanization accelerators, and other chemicals are compounded in-house.

The specifications of the chemicals to be used and the amount to be blended are indicated and judged by computer to prevent poka-yoke.

|

|

~ Mixing ~

Kneading is an important process to evenly disperse the compounding chemicals into the raw rubber.

This process produces stable molding quality.

Kneader:1 unit (55L)

|

Two Roll Mill:2 units (16/14 inch)

|

|

Aging (lowering the temperature) is performed to stabilize the properties of the kneaded material.

|

|

~ Material Cutting ~

Cutting Machine:2 units (for Compression)

|

Cutting Machine:2 units (for Injection)

|

|

By optimizing the material volume for compression molding, we can stabilize the molding quality and reduce the amount of scrap.

|

|