|

เราได้จัดแสดงในงาน NEPCON THAILAND2024 ซึ่งจัดขึ้นที่ไบเทค

ขอบคุณสำหรับการเยี่ยมชมเรา

วันและเวลา : 19 - 22 มิถุนายน 2567 10:00-18:00 น.

สถานที่: ศูนย์นิทรรศการและการประชุมไบเทค (ไบเทค)

|

|

|

|

|

|

|

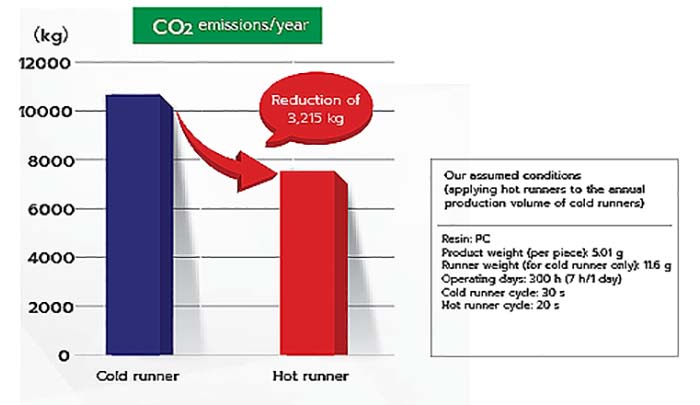

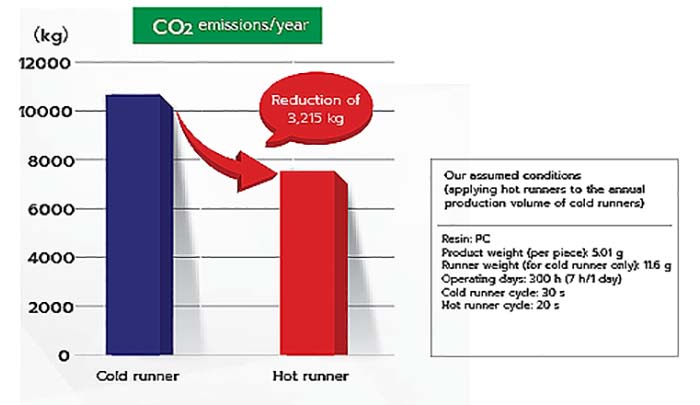

CO2 Reduction Effect

by runnerless system

|

|

Hot runners reduce plastic waste and contribute to the SDGs

|

CO2 Reduction Effect

|

No need to cool the runner - this allows for shorter cooling times. As production efficiency improves, equipment operating time can be reduced and unnecessary energy emissiona are prevented.

The utmost feature of hot runners is that they do not discharge runners during molding. This minimizes waste plastic and contributes greatly to reducing CO2 emission.

|

▲ Click and Enlarge to see ▲

|

Upgraded energy-saving performance of the SEIKI hot runner!

|

|

Improved insulation performance

|

SEIKI's unique insulation structure dramatically improved the thermal efficiency within the hot runner system.

Reduction in manifold weight

|

The lightweight manifold significantly reduced energy consumption during temperature rise. It also requires minimal energy during molding.

|

Achieves a reduction in power consumption of more than 30%

|

Would you like to join us in caring for the environment?

|

SEIKO CORPORATION Work on converting biodegradable plastics and biomass plastics into hot runners by using its abundant track record and know-how in hot runner conversion over more than 50 years.

We propose the optimal solution, hot runners, to alleviate customer concerns through material prototyping at our Head Office Factory and various analyses as well as implementation examples.

|

|