Matsumoto Kosan (Thailand) Co.,Ltd.

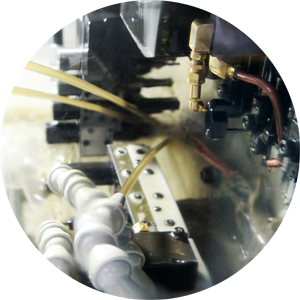

Consistent production from the bar material, precision metal machining cutting work by high-performance CNC composite lathe

Home| Products | Technology | Equipment | QC | Process | Company Profile | Gallery | Contact Us

Stable supply by consistent production

In our company we carry out a consistent production from the bar material.

Processing complex shapes by once set up

High-performance CNC lathe can also correspond to the difficult production.

Producing high-precision products

The factory which the constant temperature controlled at ± 2.0 ℃ (24 hours full operation),

high-precision products of ± 2 microns can be produced stably.

Perfect quality control system

We use "air micro" equipment that can measure circle diameter 0.1 micron to measure high-precision equipments and all goods inspected by the human eyes, too.

| Japanese (Kuboyama) | kuboyama@mkk-thai.co.th | |

| Thai (Parinyarat) | sales1@mkk-thai.co.th |

|

SUBCON THAILAND 2024 Information | ||

|

NEWS | Latest Update: Jul 2018 |

Matsumoto Kosan (Thailand) Introduction video

|  |

CONTENTS |

| The automotive parts as our main work with high-quality and high-precision have been sent out to the world in a wide range of business areas. |

| We have established the machining technology that would satisfy Q · C · D needs. |

| High-precision machining parts in micron unit can be produced by the latest composite CNC lathe in theconstant temperature factory. |

| A quality assurance system that responds to the customers' trust has setablished. |

| We are actively promoting rationalization and efficiency in each process. |

| As a part of the global strategy of MKK, we began from October 2012. The Thai factory as a starting point was expaned in October 2015 to strive to globalization of further business. |

| The main factory in Japan as a mother factory works closely with Thai factory and aims to develop world-wide business. |

| Please contact us ! |

| MKKT's Gallery |