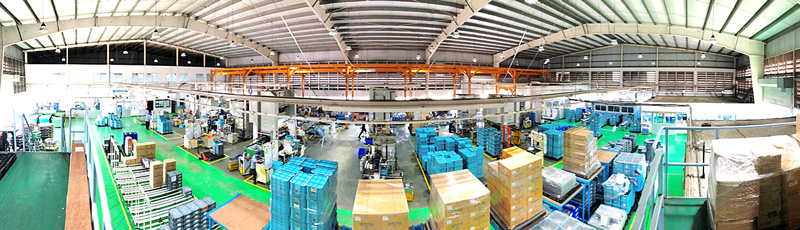

Press Production Line |

|

|

|

|

By Combining Manufacture of precious press processing and tap , we respond to cost reduction and short delivery time.

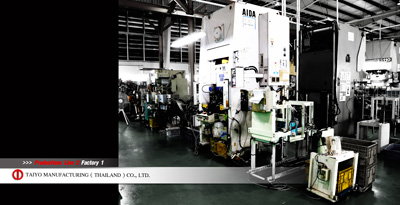

Factory 1 Press equipment |

|||

| Precision Link Motion (Inner Tapping line) | AIDA / JAM | NS1-1100 / SPS505 | 1/1unit |

| Precision Link Motion (Inner Tapping line) | AIDA / KOMATSU | NS1-1100 / OBS25 | 1/1unit |

| Precision Power Press (Inner Tapping line) | KOMATSU | OBS110 / OBS25 | 1/1unit |

| Precision Power Press (Inner Tapping line) | KOMATSU | OBS110 / OBS60 | 1/1unit |

| Precision Eccentric Motion Press | KOMATSU | E2W200 | 1unit |

| Precision Eccentric Motion (Inner Tapping Line) | KOMATSU | E2W200 / OBS15 | 1/1unit |

| Precision Power Press | KOMATSU | OBS110 | 1unit |

| CNC Precision Control Free Motion Press | AIDA | NS1-1500(D) | 1unit |

| Precision Eccentric Motion Press | KOMATSU | E2W160 | 1unit |

| Precision Power Press | KOMATSU | OBS110 | 1unit |

| Precision Power Press | AIDA | NS1-80 (S) | 1unit |

Factory 1 Degreasing Machine |

|||

|

Hydrocarbon Degreasing Machine |

CLEANVY |

FVH3-4260V2CV | 1units |

|

|

Precision Link Motion (Inner Tapping line) Precision Link Motion (Inner Tapping line) AIDA/JAM NS1-1100/OBS25 AIDA/JAM NS1-1100/OBS25 |

CNC Precision Control Free Motion Press CNC Precision Control Free Motion Press AIDA NS1-1500 AIDA NS1-1500 |

Factory 2 Press equipment |

|||

| Precision Power Press | AIDA | NC1-110 | 1unit |

| Precision Power Press | AIDA | NC1-110 | 1unit |

| Precision Power Press | KOMATSU | OBS110 | 1unit |

| Precision Power Press / Servo Press (Tapping Line) | AIDA / KOMATSU | NC1-80 / H1F35 | 1/1unit |

| Precision Power Press | AIDA | NC1-80 | 1unit |

| Precision Power Press | AIDA | NC1-80 | 1unit |

| Precision Power Press | KOMATSU | OBS15 | 1unit |

| Precision Servo Press | KOMATSU | H1F35 | 1unit |

| Precision Eccentric Motion Press for Aluminum case | KOMATSU | E2W160 / OBS15 | 1/1unit |

| Precision Power Press | AIDA | NC1-80 | 1unit |

| Precision Power Press | AIDA | NC1-80 | 1unit |

| Precision Eccentric Motion Press for Transfer-Line | KOMATSU | E2W200 Transfer-Line | 1unit |

| Precision Power Press | AIDA | NC1-80 | 1unit |

|

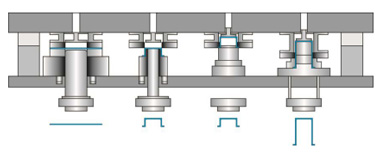

Transfer-Line 200t

Concept of Process Transfer Precision Press Process will use TRANSFER DIE that has more than one stage and use automatic system to transport part with stage by stage during opening die each step until finished. Advantage of stamping by Transfer die 1. Each stage is separately , easy to maintenance. |

Factory 3 Press equipment |

|||

| Precision Eccentric Motion Press | KOMATSU | E2W300 | 2units |

| CNC Precision Control Free Motion Press | KOMATSU | H1F200 | 2units |

| CNC Precision Control Free Motion Press | KOMATSU | H1F110Q-2 | 1unit |

| Precision Power Press | AIDA | NC1-110 | 1unit |

Mold Production Line |

|

|

|

|

Mold equipment |

|||

| CAD / CAM System | TAIYO MECHATRONICS | TASCAM | 1unit |

| CNC Wire-Cut Electrical Discharge Machine | SODICK | AQ535L | 1unit |

| CNC Wire-Cut Electrical Discharge Machine | SODICK | VL600Q / VZ500L | 1unit/1unit |

| High Speed Milling Machine | SODICK | HS430L+LN2X(E32) | 1unit |

| Vertical Machining Center | OKK | VC51 | 1unit |

| CNC Die-Sinker Electrical Discharge Machine | SODICK | AD25L+IN1 | 1unit |

| Surface Grinding Machine | OKAMOTO | ACC63SA | 1unit |

| Forming Grinding Machine | OKAMOTO / KURODA | ACC515DXCR / GSBM3 | 3units/1unit |

| Carbite Tool Grinding Machine | TSUGAMI | CTG-4 | 1unit |

| High-Speed Small-Hole Drilling Machine | SODICK | K1C | 1unit |

| Lathe Machine | WASHINO | LAS-55A | 1unit |

| Milling Machine | SHIZUOKA | VHR-A | 1unit |

|

|

High Speed Milling Machine High Speed Milling Machine |

CNC Machining Center CNC Machining Center |

|

|

WireCut EDM WireCut EDM |

Surface/Forming Grinding Machine Surface/Forming Grinding Machine |

|

|

Mold maintenance Mold maintenance |