You may know that the composition of degreasing agents in Osaka and Tokyo is different due to the difference in water. It is necessary to change the composition of degreasing agents according to the water quality in your area. In addition, the adhering oil (anti-rust oil, cutting oil, working lubricant etc.) is constantly developing, and so the degreasing agents is also required to be developed. We can create your own pretreatment agent by selecting and adjusting the chemicals according to your products and cleaning process. |

Please contact us if you have any troubles TEL / FAX / E-mail |

|||

|

||||

|

Consultation Let us know your problems and worries |

||||

|

►Pre-treatment process consulting ①To understand the current problem in more detail, analyze the product surface with SEM/EDX. ②In the case of poor degreasing processes, perform SEM analysis on the raw material before the process. → We can select a suitable component for the product based on the results. ③Perform lab tests and scale-up tests before the actual process line. ④Perform surface analysis before and after degreasing to confirm removal of the processing oil and its additives. ⑤Perform plating and confirm the degreasing ability. ⑥Report the test results and confirm whether it is possible to perform tests in the actual line ⑦Explain the selected components of the degreasing agent, characteristic points, and how to use, etc., then go forward to the actual line test. |

|

|||

|

Consider about your problems |

|||

|

|

|||

|

・Analyze your problem ・Joint development (order-made) ・Propose your own pre-treatment processes |

||||

|

||||

|

Test on your products Test in your actual working conditions |

||||

|

||||

|

Meeting for delivery date |

||||

|

||||

|

Delivery of proposed degreasing in product We will provide the best products for your company. |

||||

Metal surface treatment agent "Gildeon series" Chuo Kagaku (Gildeon Thailand) |

[Materials] Iron, stainless steel, copper and copper alloys, zinc alloys, aluminum alloys, plastics, etc.

Use |

① Plating pre-treatment chemicals (immersion degreasing, electrolytic degreasing, ultrasonic cleaning, acid cleaning, etc.)

② Parts cleaning chemicals

③ Drum can cleaning (drum can recycling cleaning)

④ Solvent cleaning (alternative chlorine-based solvent, alternative chlorofluorocarbon, etc.)

⑤ Cleaning agent for food industries (scale removal, bottle washing, equipment washing, antibacterial cleaning, etc.)

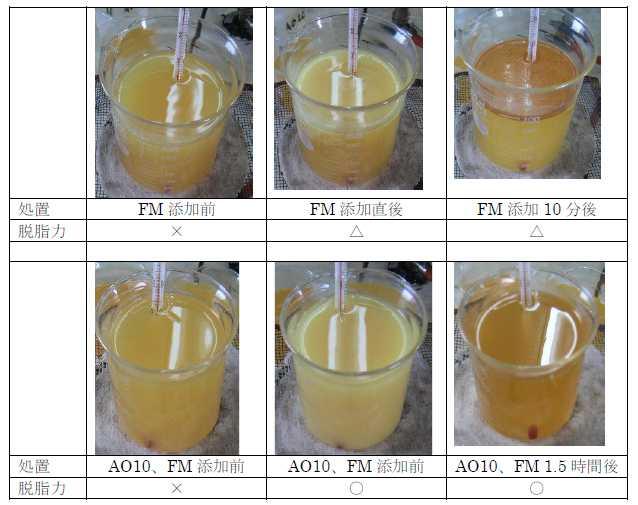

Degreasing ability recovery (Test) |

1-1 Add 0.5% FM to separate oil ⇒ Oil separation is good, but recovery of degreasing power is low.

1-2 Add 1% of AO10⇒ Recovery of degreasing power was observed.

1-3 Add AO10 and FM (1%, 0.5%) in the same time ⇒ Oil separation became gentle and degreasing power was recovered.

This test is a batch-type regeneration process outside the process, but we have also established a PE process that enables the above oil separation and recovery process while performing metal cleaning.