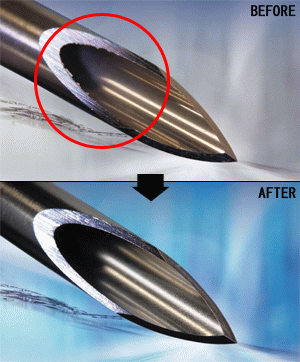

NEPLOS treatment is a chemical polishing process

|

|

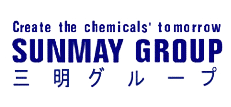

NEPLOS treatment is effective for deburring and surface gloss finishing in small uneven places and thin tubes found in medical injection needles, suture needles, and electronic parts such as hard disks, while electrolytic or mechanical polishing is not applicable. The surface after NEPLOS treatment is stable and does not generate rust due to the passivation function. By controlling the processing time in seconds and minutes, the polishing amount can be controlled on the order of microns, and stable product quality can be obtained. |

Basic Idea of NEPLOS Process |

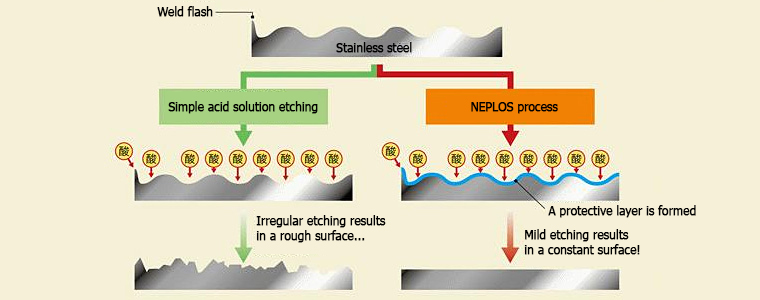

Basic Process |

Compatibility of NEPLOS Polishers with Major Metals & Alloys |

| Stainless Steel | Nickel Inconel | ||||||

| Austenitic | Martensite | Femite | |||||

| SUS303、304、XM7 Lost Wax SCS13、14 |

SUS316、316L | ||||||

| Polishing | Burr removal | Polishing | Burr removal | Burr removal | Burr removal | Burr removal | |

| New #505 | ○ | ○ | △ | △ | △ | △ | ○ |

| #507 | ○ | ○ | ○ | ○ | △ | △ | ○ |

| Aluminum | Copper/brass | Iron |

Pure titanium / |

|

| #27・AI | ○ | |||

| #103-M, #103-M2 | ○ | |||

| L-11 | ○ | |||

| #601 | ○ |

Examples of NEPLOS Process |

|

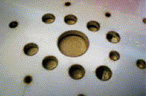

Material:SUS304(Polishing) |

Material:SUS304(Burn mark removal) |

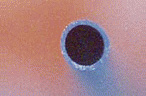

Material:Pure titanium(Burr removal) |

|||

|

Before Processing |

|

|

|

||

|

|

|

|||

|

After Processing |

|

|

|

Q & A |