Fine bubble will solve your water rinse problem in plating !

Fine bubble generator

|

|

● No moving part

● Attachable to your current facilities

● Resistant to foreign contamination

● Easy maintenance

|

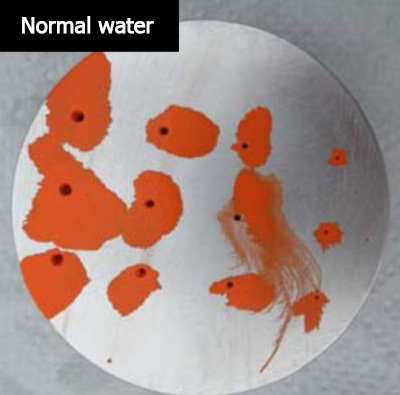

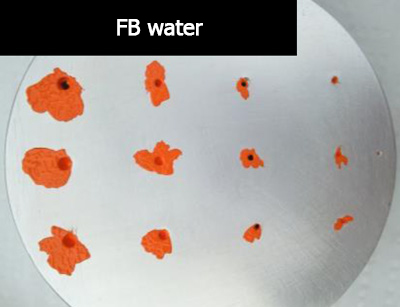

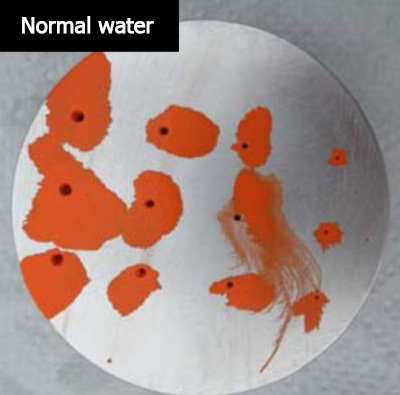

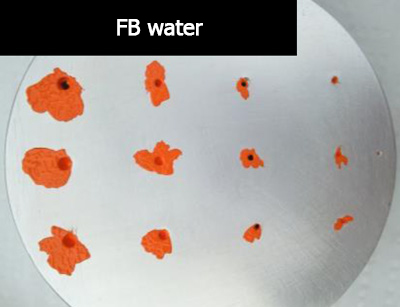

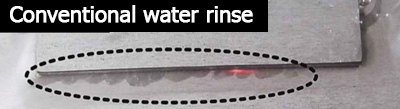

FB water itself can remove greasy stain!

< Cleaning of colored rust preventive oil. >

|

|

|

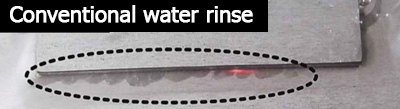

FB can wash even narrow gaps !

< Improvement of oil exudation at welded part >

|

|

|

|

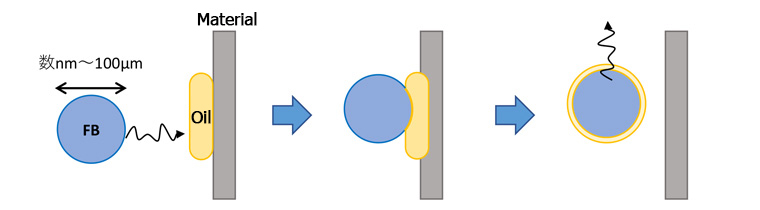

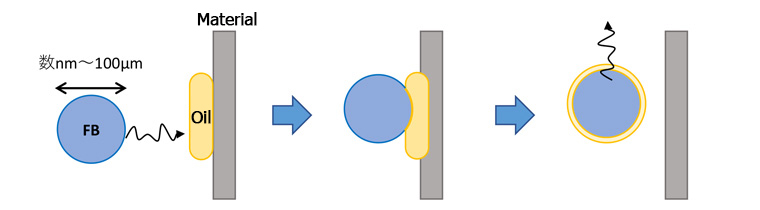

Fine bubble:fine bubbles less than 100μm

1-100μm: micro bubble

less than 1μm: ultra fine bubble

(JIS B 8741-1)

|

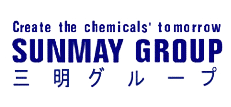

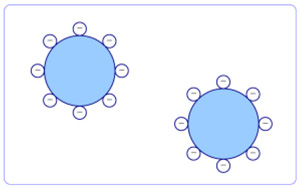

■ Charged surface

|

FB are negatively charged and repel each other, thus they do not combine. FB can adsorb positively charged organic substances, etc., resulting in the cleaning function.

|

|

|

|

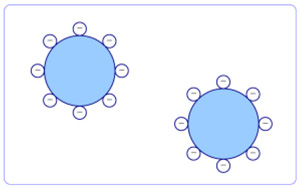

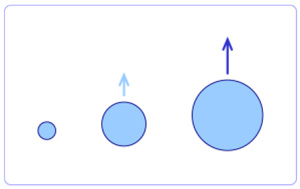

■ Slow ascent to the water surface

|

Normal bubbles rise to the water surface quickly and disappear. FB have a very small volume, so rise to the surface very slowly and stay in water for a long time.

|

|

|

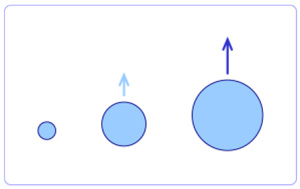

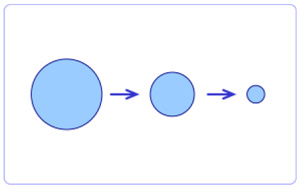

■ Self-pressurizing effect

|

As the diameter of the bubble decreases, it gradually shrinks due to surface tension. Therefore, the gas dissolves efficiently in bubbles.

|

|

|

Degreasing function of FB: Hydrophobic surface

|

Fine bubbles with degreasing function enter into small gaps and clean out!

| 【Application】 |

| ・Improving cleansing power |

・Precise cleaning of complex parts |

・Cleaning of gaps |

| ・Prevention of stains on plating |

・Cleaning after blasting |

・Cleaning forging |

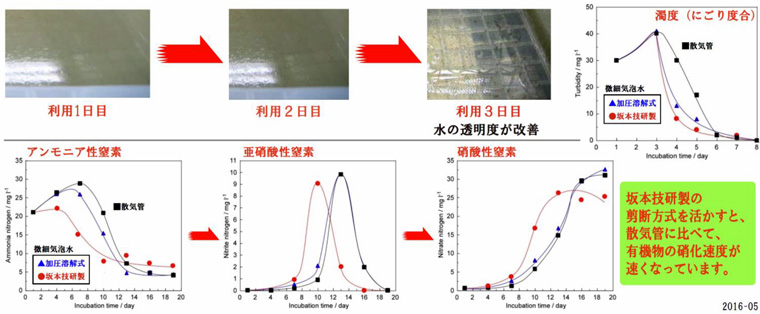

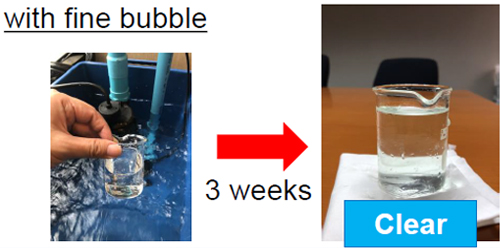

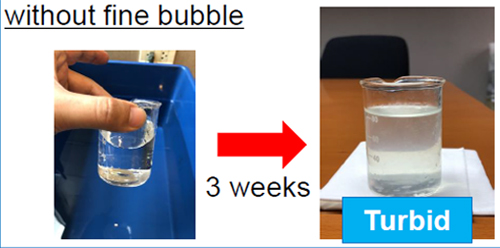

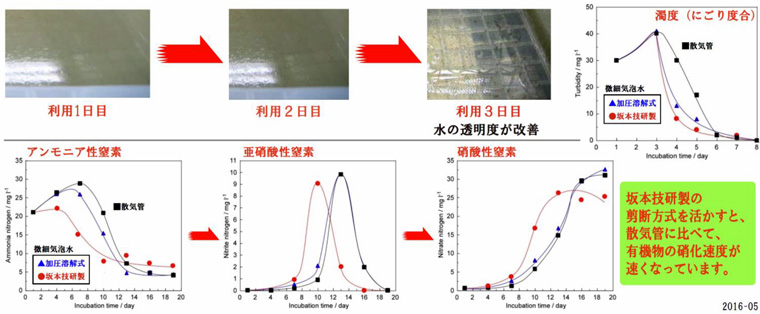

Bacteria growth suppression

|

■Sample: DI water 30 L + ENP liquid 0.3 L (modeled on the first electroless nickel-phosphorus washing tank)

■ Conditions: Room temperature

Bacterial growth was suppressed by the operation of the fine bubble generator

| 【Application】 |

| ・Prevention of bacterial growth in the recovery tank of precious metal plating |

・Prevention of putrefaction of the recovery solution of precious metal plating |

|

Q.

|

Which model should be chosen?

|

|

A.

|

Please choose the model according to the bath size.

100-150 L → 15 A (Pump capacity: 0.15 kW)

200-400 L → 25 A (Pump capacity: 0.25 kW)

More than these, you can install multiple.

|

|

Q.

|

How to use the fine bubble generator effectively to remove plating stains?

|

|

A.

|

You can install either water washing after plating and / or water washing before plating.

|

|

Q.

|

Is there any bad effect on the quality of plating?

|

|

A.

|

There have been no adverse effects so far.

|

|

Q.

|

How to install it?

|

|

A.

|

Just connect to the circulation pump and piping!

By installing the bubble discharge port toward the products, the cleaning effect by the jet can be also obtained.

|

|

Q.

|

Is maintenance difficult?

|

|

A.

|

Basically only the intake filter. The filter part can be washed with water, so you can wash it with water or warm water and then clean it with an air blow.

|

|

Q.

|

Why can't bacteria grow?

|

|

A.

|

The internal flow velocity of the fine bubble generator is 15-17 m / s, and a strong shearing force is applied. It is believed that this shearing force causes bacterial cells to break as they pass through the generator.

Bacteria multiply twice, so 24-hour operation is recommended for this purpose.

|

|

Q.

|

What are the conditions for using the fine bubble generator?

|

|

A.

|

As it is made of ABS resin, the operating temperature and chemical resistance are the same as ABS resin. Basically, please use it in a water rinse bath at 60 ℃ or less. It cannot be used in strong acid / alkaline solutions.

If you wish to use it in such an environment, it is also possible to manufacture the generator with Teflon resin or SUS316.

|

|

Q.

|

Comparable to ultrasonic cleaning?

|

|

A.

|

With ultrasonic waves, the irradiated surface is strongly cleaned, but it is not good at cleaning the surface that cannot be reached.

On the other hand, the physical force of fine bubbles is not as strong as that of ultrasonic waves, but since it fills the tank, a uniform cleaning effect can be obtained.

|

|

Q.

|

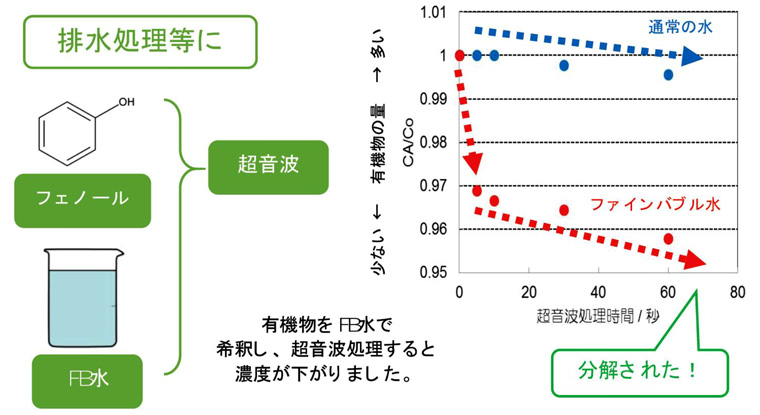

Can it be used with ultrasound?

|

|

A.

|

By irradiating ultrasonic waves after generating fine bubbles, extremely strong cavitation is generated and a stronger precision cleaning effect can be obtained.

|

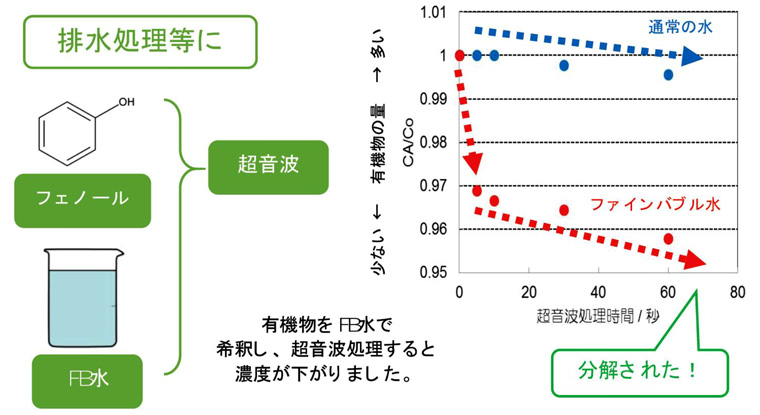

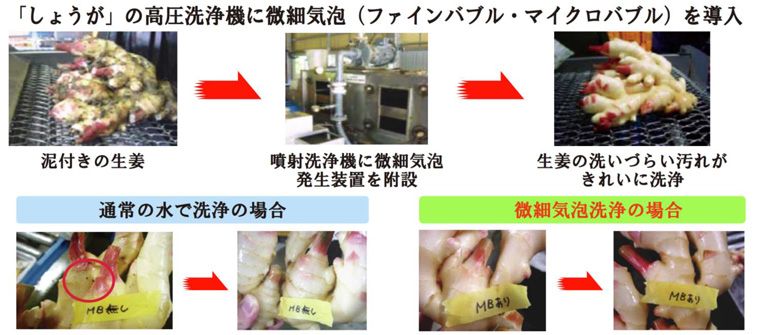

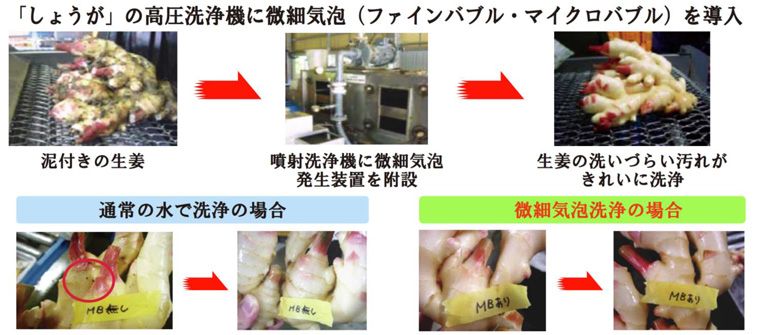

■ 農作物の洗浄

■ 活魚の生存率向上/活魚槽の清浄化

■ 曝気・活性汚泥法の効率化

■ 超音波併用による有機物分解の促進