Reduce factory energy waste, Reduce CO2 emission

Hitachi provides various ideas and products which can minimize customer’s energy consumption level and CO2 emission. By checking local operating conditions, we will provide sufficient solution to cover those needs.

High efficiency equipment + Professional knowhow of energy saving |

|

Hitachi can support customer’s energy saving works by providing high efficiency equipment and professional knowhow which collected through 110years of industrial supply experience. Also provide actual measuring service to each purchased customers so that not only installing equipment but can be sure with those installation effects. |

|

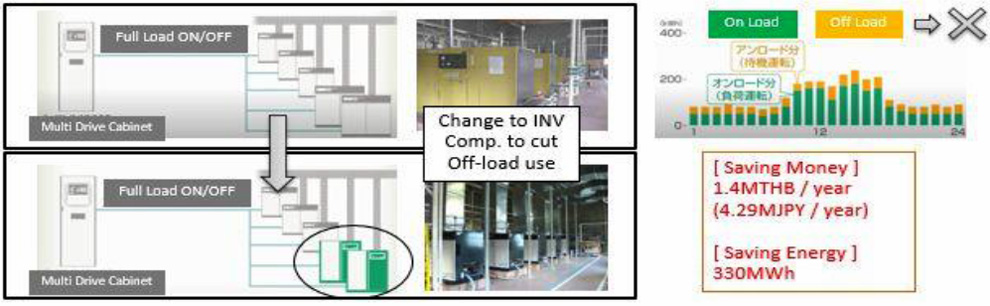

<Case 1> Multi control & Inverter operation of Compressors |

Compressors will have energy waste if their OFF-Load periods becomes longer. Hitachi can provide appropriate energy saving proposal by considering total air requirement, what approach shall be the most effective to reduce customer’s energy waste.

Below is energy saving case which suggest single speed compressor to be replaced as Inverter compressor and modified as multi control operations. Depending on available budget, we will select and advice the effective approach for return of investment.

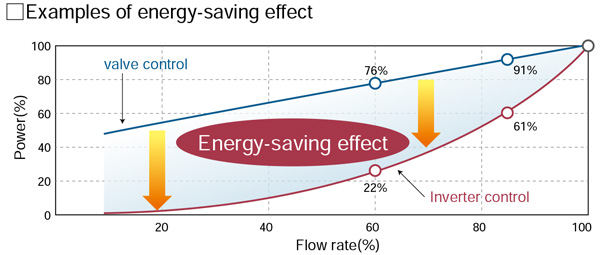

<Case 2> High efficiency & Inverter switching on Fan & Pumps |

|

|

By switching valve control to inverter operation, user can reduce total power consumption by directly cutting off power output on equipment. Hitachi check actual unit condition and collaborate with other related parties (Such as fan & pump manufacturer) so can provide appropriate enhancement which can effectively cover investment. |

By replacing motor to high efficiency units, user can reduce energy consumption per required outputs. Hitachi is always visiting local customer, measure actual load level and shall propose workable solution to effectively achieve those goals. |

|