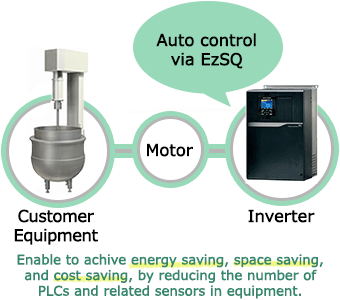

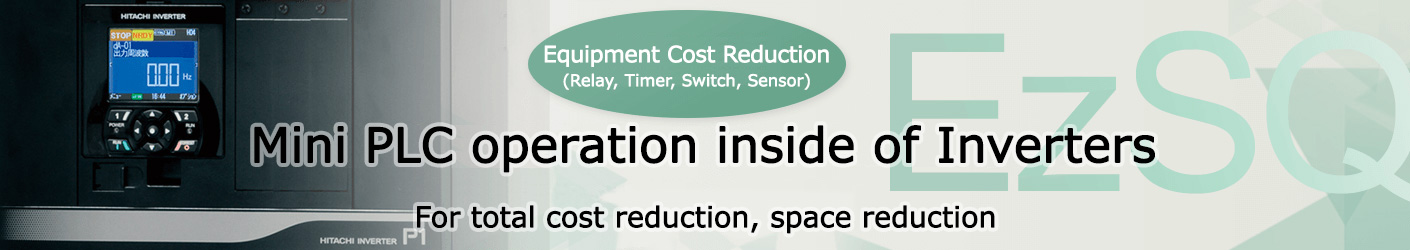

Hitachi inverters are having mini PLC functions as standard (EzSQ).

By using this function, enable to reduce external device such as PLC,

sensor and timer units to minimize cost of equipment.

EzSQ Use cases |

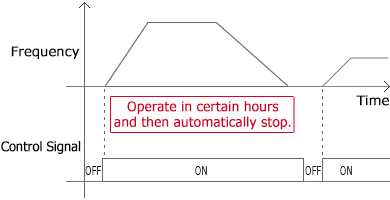

〈 Use Case 1 〉Mixer Units |

By prepare auto control function combining with internal timers, enable to reduce PLC and sensor units which made smaller space and lower cost on total equipment production.

|

|

〈 Use Case 2 〉Conveyers |

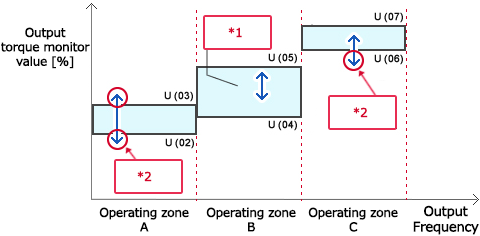

Automatically detect conveyer errors by monitoring each motor torque outputs and correct whenever any irregular condition occurred and detected.

- Prepare allowable torque range on each operation and switch to correcting operation if abnormal detection has been recognized.

|

(*1) Automatically judge machine operation status by tracking whether the output torque value is within the allowable band. (*2) If the number of irregular cases detected more than expected, machine will automatically reduce speed to make soft delivery. |

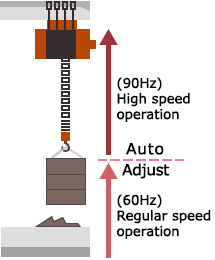

Reduce operation time (Example case for Hoist manufacturer) |

Enable to have effective operation by auto adjusting its winding up speed. For example, when load is light automatically adjust speed in high speed and when load is heavy automatically adjust speed in slow speed.

This load level monitoring can be done by monitoring overload prediction signal which availalbe inside of inverter. By having this function available without using PLC and additional sensors, it will give machine manufactuer to reduce cost, space and sometimes provide additonal value of energy savings.

|

|

New Function Development, welcome and pleasedKindly let us know your thoughts first. Small start is always welcome. |