Subcon Thailand 2025 (May 2025) |

|

We exhibited at SUBCON 2025. Exhibited products ●Silicone 3d printer "SILICOM" ●3D printer filament: ●Resin extrusion products: |

Exhibition landscape in 2025 |

|

|

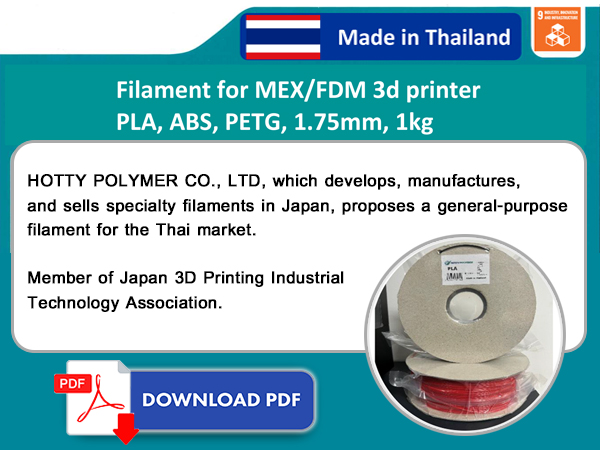

3D printer filament |

|

Silicone 3d printer "SILICOM" |

SLICOM Printed sample |

|

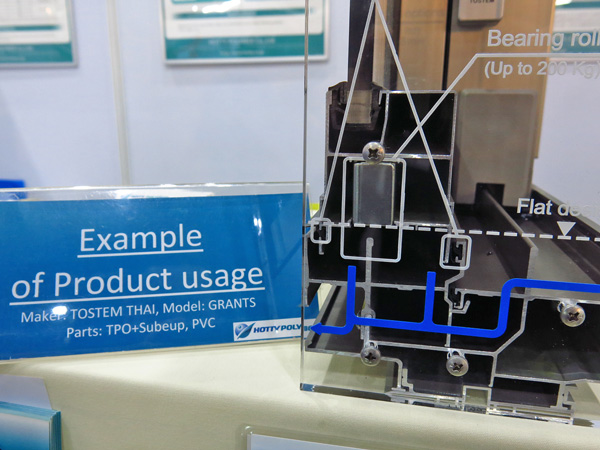

Resin extrusion products |

TOSTEM THAI社の窓枠ユニット「GRANTS」に |

"Sube-Up®" Reduces PM2.5 infiltration (March 2025) |

"Sube-Up®" is a high-sliding, wear-resistant, and anti-contamination resin extrusion product developed by Hotty Polymer Co., Ltd. It features a special lubricating resin coating on its surface. By adopting them as airtight components for windows and doors, the airtightness can be improved compared to existing parts, which is expected to reduce the infiltration of PM2.5 and provide a more comfortable living space.

Typically, polyolefin-based elastomers consist of materials with rubber dispersed within resin, and their extruded surfaces tend to have low slip properties. When used as sealing materials or gaskets, they often exhibit high friction, strong adhesion to counterpart materials, and a tendency to become easily contaminated. "Sube-Up®" addresses these challenges with its unique surface coating, offering the following features:

■ High Sliding Performance: Provides a coefficient of friction comparable to fluororesin, ensuring excellent smoothness.

■ Outstanding Wear Resistance: Offers greater wear resistance than nylon, contributing to longer product life.

■ Enhanced Formability: The thin coating of approximately 15–30μm does not affect the physical properties of the base material.

■ High Hygiene Standards: Since no plasticizers are used, it is resistant to mold and dirt buildup.

■ Cost Efficiency: The simultaneous molding process eliminates the need for secondary coating and solvents, making it environmentally friendly and cost-effective.

■ Superior Anti-Contamination: The surface is easy to clean, and its water-repellent properties prevent dirt accumulation even when used outdoors.

"Sube-Up®" enhances the performance of sealing materials and gaskets and is expected to find applications across various industries.

Notice regarding "Capital and Business Alliance"

|

We are pleased to announce that on July 29, 2024, our company and Nakano Manufacturing Co., Ltd. (3-17-16 Hosoda, Katsushika-ku, Tokyo) have entered into a capital and business alliance.

In the future, through close cooperation between the two companies, we will strive to propose products that satisfy our customers and provide even better services. We would appreciate your continued support and patronage of both companies.

■ Nakano Manufacturing Co., Ltd. Website

http://www.nakasei.co.jp/index.shtml

Subcon Thailand 2024 (May 2024) |

|

■ Booth: F28 We exhibited at SUBCON 2024. Exhibited products Resin extrusion products: Sve-up products, resin tubes |

Exhibition landscape in 2024 |

|

|

HP filament |

|

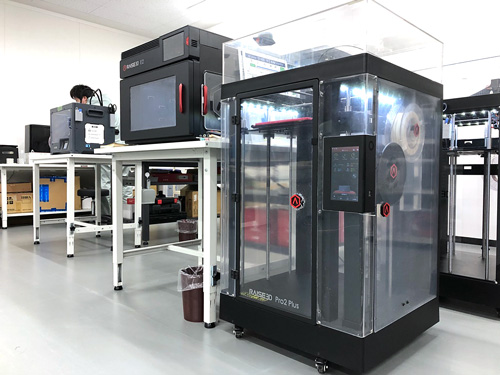

RAISE3D printer |

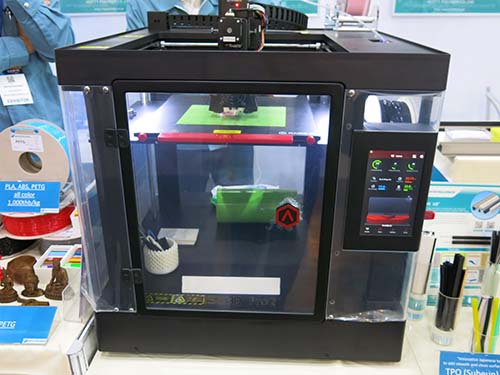

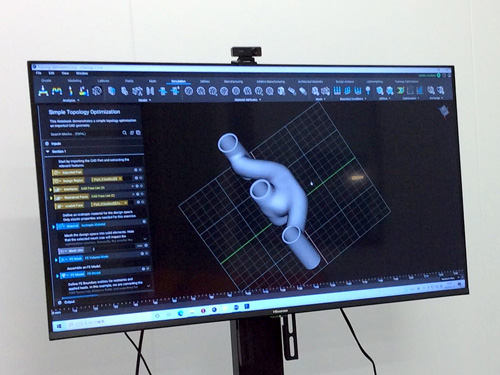

3D printer modeling demonstration |

|

Printed samples for the medical industry |

Printed samples for the medical industry |

|

Molding samples unique to Thailand |

|

Exhibition landscape in 2023 |

|

|

|

|

|

|

A 3D printer showroom including a conveyor type has been completed at the Thai factory! (January 2023) |

|

PLA printing of very long products is possible with a conveyor transfer system. 2 meter samples are available. |

We can print from general materials such as PLA and ABS to our own unique super flexible filament. Hotty Polymer's 3D printer "SDS I" is also on display. You can check the specifications by operating the actual machine. |

Opened a large 3D printer showroom at the Kuki Factory (Jan 2022) |

|

In November 2021, our parent company, Hotty Polymer Co., Ltd., opened a large 3D printer showroom boasting 100 square meters in the Kuki factory, our main production base. In Kanto area's largest showroom, you can see various models such as MEX, FDM method, silicone rubber 3D printer, in-house developed 3D printer, stereolithography, etc. at once. All models are on display in operation, and we also support sampling orders from users. Please experience Hotty Polymer's 3D printer once. |

"Green Industry Level 2" certification by the Ministry of Industry of Thailand |

|

|