As a polymer solution company,

we contribute to a sustainable society.

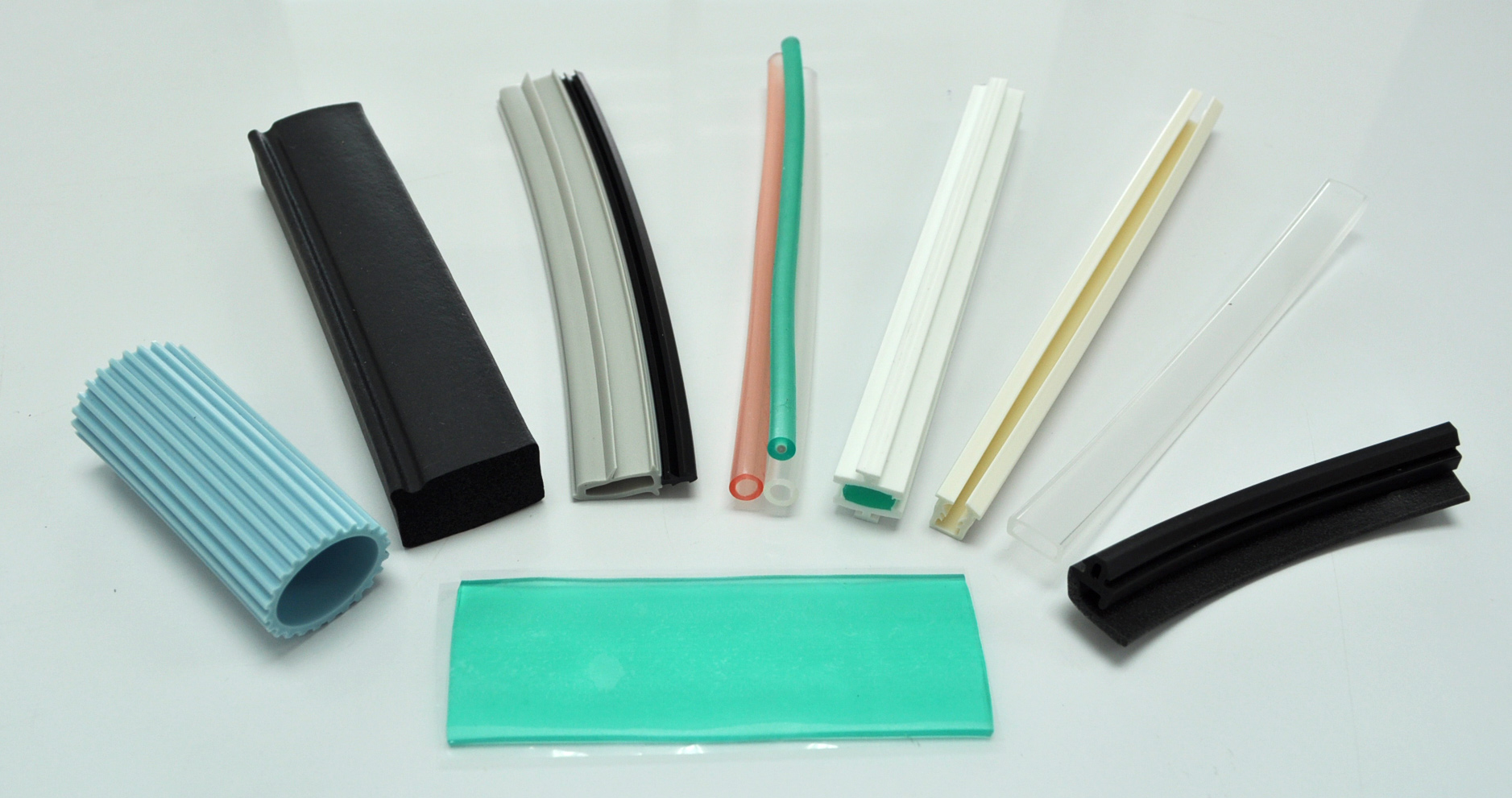

We have carved out a unique path with extrusion molding technology for polymer materials.

We provide our high-performance parts with high technology and high quality to many fields centered

on the construction / civil engineering field and the automobile field.

Since TPO has a specific gravity of 1 or less, it is possible to reduce the weight of the product,

and the amount of heat generated in the manufacturing process is also small. TPO is a recyclable environmentally friendly material that contributes to the reduction of greenhouse gases.

Company Profile 2023 (9:11) (0:53)

Sube-up

Excellent smoothness surface and abrasion resistance resin extrusion products.

"Sube-Up®" By adopting them as airtight components for windows and doors, the airtightness can be improved compared to existing parts, which is expected to reduce the infiltration of PM2.5 and provide a more comfortable living space.

Applications

Gaskets, air-tight materials, water-tight materials, automobile parts, electronic parts and leisure parts etc.

For Details

HOTTY 3 point powers produce high-performance products.

Problem Resolution – suggestion – Rapid Implementation.

We propose various materials and profile designs in response to our customers’ needs.

High technology and latest manufacturing process

In line with the rapid changing times, newest raw material, manufacturing process. We also continue to develop new extrusion technology and quality control system.

Co-operate with parent company in Japan to produce high-quality products for satisfying of customers’ needs.

From part experience of parent company in Japan, we provide the best solution to serve Thai customers’ needs.

We have developed

the Plastic Foam products

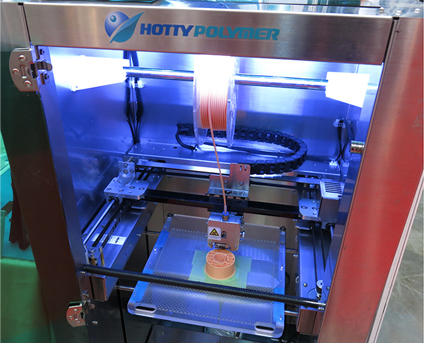

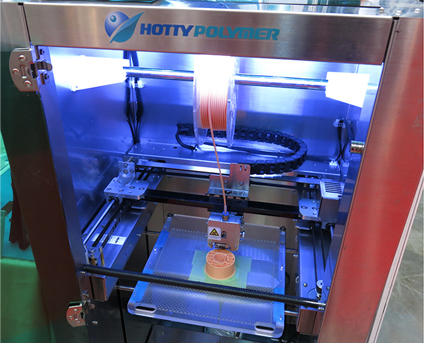

3D Printer, Filament

Printing service