One-Stop Production System:

From R&D to Finished Products

Mold-Making

We have ample experience in injection and metal pressing mold-design and mold-making. To realize speedy and highly precise R&D, we make use of skillful techniques and well-trained personnel to cope with customers’ needs.

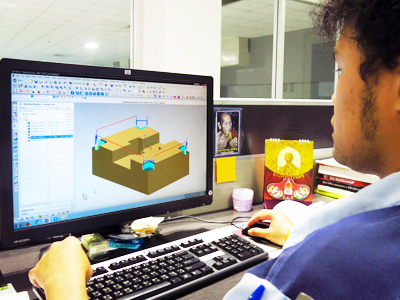

Specifically speaking, we design an injection mold by making use of mold flow analysis software to secure both the mass productivity and assure the best quality.

|

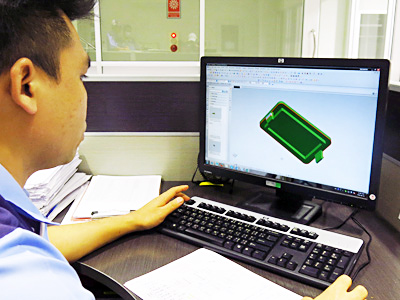

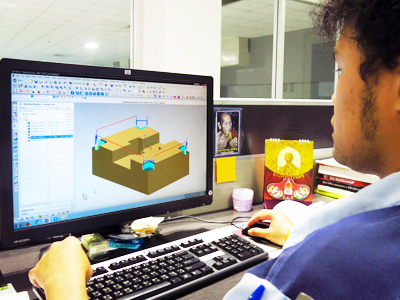

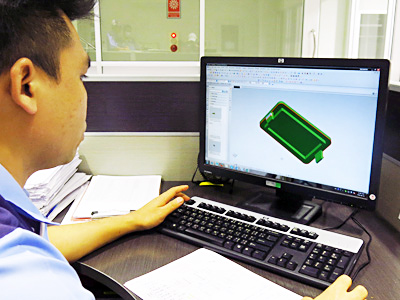

CAD

|

NX

|

|

Machining Center [MAKINO]

All 7 units

|

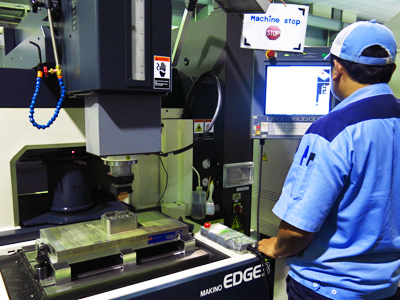

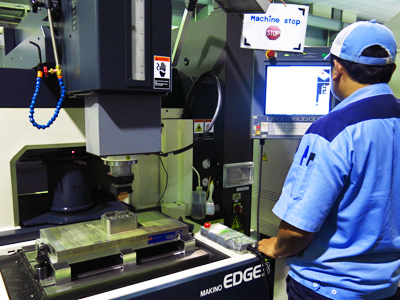

Electric Discharge Machine [Sodick / Makino]

All 3 units

|

|

Wire-Cut Machine [Sodick / Makino]

All 4 units

|

Surface Grinding Machine [Okamoto]

All 4 units

|

|

Craftsmanship of Polishing, Finishing & Mold Fitting

|

Storage of Mold Making / Repairing Parts

|

▲Top of the page へ

Plastic Injection

Plastic injection is the starting point of our mass production process. We are specialist in insert molding of precise automobile parts industry. We have a wide range of production items such as high precision exterior parts, high precision mechanism parts, and three-dimensional exterior parts.

|

Horizontal molding machine

18t~350t [Sumitomo] All 43 units

|

Vertical molding machine

100t [JSW] 3 units

75t [Sumitomo] 2 units, All 5 Units

|

|

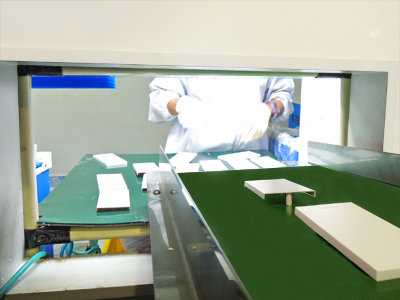

Keep production clean by separating material supply, worksite and inspection areas.

|

|

Fully Automatic Runner Cutting Process

|

Computerized Production Management

|

▲Top of the page へ

Surface Mounting(SMT)

High Density Mounting from Single-sided to Multi-Layers

| Minimum board size |

Maximum board size |

Part size |

| L50×W50 mm |

L330×W250 mm |

0402~45×100mm Height > 6.5mm |

|

|

YS12F, YS12P, YCPⅡ [Yamaha Line]

|

|

LED Lighting Mounting

|

|

Metal Pressing

|

In-house metal pressing production to supply metal conductive parts for insert-molded (integrated molding) of electrical components for automobile industry.

By this in-house metal pressing process, we can realize speedy and high quality with low cost production.

Progressive Servo Pressing Machine

110T [Aida]

|

|

▲Top of the page へ

Painting and Printing

|

|

Printing Masking Set with JIG

|

|

Manual Spray Painting by Skilled Personnel

|

|

|

|

Hardening and Drying Process

|

|

Tampo Printing for Cubic or Curved Surface

|

|

Device/Module Assembly

|

Laser Engraving or Laser Marking

|

▲Top of the page へ