Degreasing agent for Printed Circuit Board (PCB)

Melplate PC-316 / PC-316 Conc. |

|

Acid degreasing agent for Printed Circuit Board (PCB) that use to remove oxide film, dry film residue, dirt, etc. on the copper surface. |

|

Suppress the occurrence of pits and suitable for pretreatment of Printed Circuit Board (PCB) patterned copper plating. |

|

No chelating agent contained. Easy to manage wastewater. |

Less damage on dry film. |

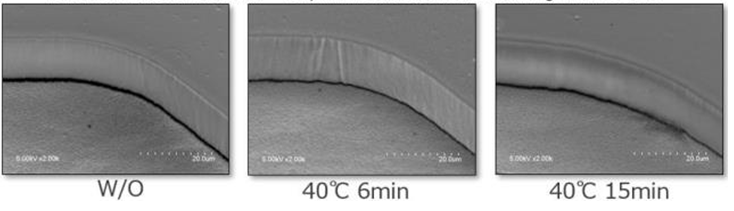

Melplate PC-316 has less damage on the dry film and effective to prevent the creeping of copper electrolyte underneath dry film, not melt the surface of the non-electroplated copper plating film. It is suitable to use as acid-based stain remover before the pattern plating process.

Dry film resist after acid cleaning with PC-316 from Scanning Electron Microscope (SEM)

Equipment |

● Tank : PVC or PVC-lined tank

● Heater : Quartz, PTFE

Precautions |

● The working solution is strong acid and high corrosive. Do not mix with alkaline chemicals.

Melplate PC-6122 |

|

Acid degreasing agents for pattern copper plating in Printed Circuit Board (PCB) manufacturing process. Example copper surface cleaner for electroless nickel/ displacement gold plating after circuit formation. |

|

Effectively remove grease stains like fingerprints etc. |

|

Effectively remove the residue of solder mark (solder resist) and dry film residue. |

|

Suppress the occurrence of pits in patterned plating. |

|

No Pollutant Release and Transfer Register (PRTR) substance contained. |

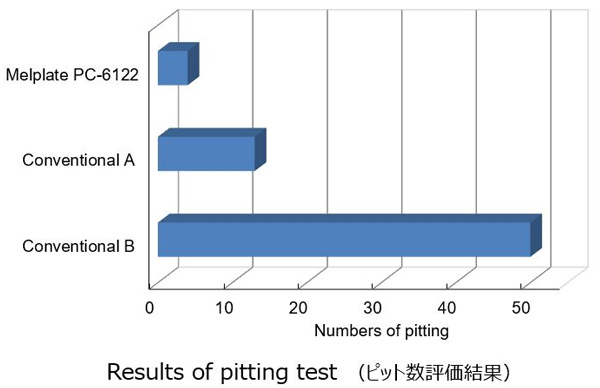

Pit suppression effect |

Melplate PC-6122 is effective in removing dry film and solder resist residue. It’s effectively in suppressing the occurrence of pit in the copper sulfate plating process and generating electroless nickel film formation.

Equipment |

● Tank : Polyethylene, polypropylene, etc.

● Heater : Quartz, stainless, PTFE heater

Precautions |

● The working solution is strong acid and corrosive. Do not mix with alkaline chemicals.

Melplate CL-1000S2 |

|

Acid degreasing agent for pretreatment of copper sulfate plating. |

|

Excellent provides effective wettability and permeability against small holes of Through-hole or inside of Blind Via Hole (BVH) that important in the formation of copper sulfate film. |

|

Low contact angle and surface tension, water can be quickly and easy to spread cover copper surface. |

|

Suppress the occurrence of pits and nodule in copper plating process. |

Contact angle and surface tension |

Melplate CL-1000S2 has a lower contact angle and surface tension than original acidic degreaser product. So, it quickly wets and spreads on the target copper surface.

| Contact angle on copper foil | ||

| Original product | Melplate CL-1000S2 | |

| Wet spread when each degreasing agent is dropped on the copper surface |

|

|

| Contact angle | 29.2° | 7.6° |

| Surface tension | 37.7 | 28.2 |

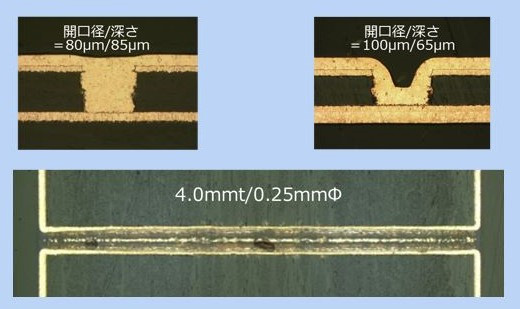

Plating in small holes of Through-Hole or BVH and high aspect ratio PCBs |

Melplate CL-1000S2 has excellent wettability, spread ability and permeability into the small hole BVH at high aspect ratio through hole PCB. Moreover, it’s effectively suppressing air voids. So, it’s useful for formation of copper sulfate film.

Equipment |

● Tank : Polypropylene、PVC、PTFE

● Heater : PTFE、quartz

Precautions |

● The working solution is strong acid and corrosive. Do not mix with alkaline chemicals.

Melplate CL-2000 |

|

Less attack on DFR. |

|

Low contact angle and excellent permeation into fine pattern. |

|

Generates less foam than conventional product. |

|

Generates less Cu etching amount than conventional product. |

|

Utilizable at low temperatures. |

Equipment |

● Tank : Polypropylene, PCV, PTFE coating tank

● Heater : Quartz, PTFE coating heater

Precautions |

● DO NOT mix Melplate CL-2000 with alkaline chemicals.

Please feel free to contact us if you have any questions or concerns about surface treatment chemicals for plating.