Copper seed layer etchant

Melstrip SE-100 |

|

The working solution is weak alkaline liquid. |

|

The galvanic corrosion caused by dissimilar metal connection is effectively suppressed. |

|

Suitable to fine pattern formation due to high selectivity to copper etching without low damage to other metals as tin, nickel and gold etc. |

|

Halogen free: it can be used with stainless steel equipment. |

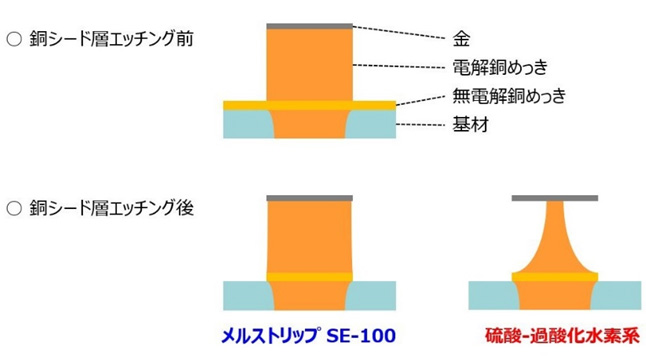

Galvanic corrosion suppression |

When etching the copper seed layer in contact with more noble metals, galvanic corrosion can occur, leading to excessive copper dissolution. Using Melstrip SE-100 helps to suppress this galvanic corrosion, effectively removing the targeted copper seed layer while protecting the dissimilar metals in contact with the copper.

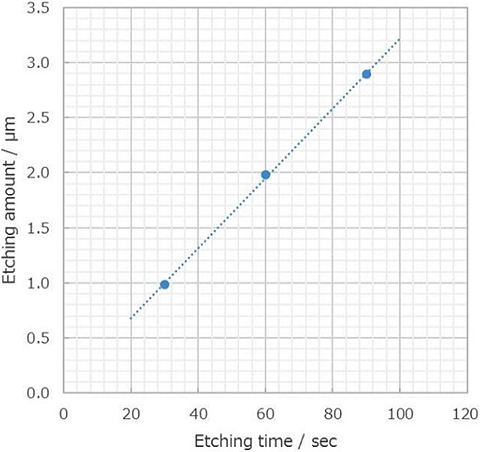

Relation between etching time and etched thickness |

|

|

The amount of copper etched increases proportionally with the etching time. By adjusting the processing time according to the thickness of the desired copper seed layer, stable copper seed layer etching can be achieved. |

Please feel free to contact us if you have any questions or concerns about surface treatment chemicals for plating.