Rubber compression Molding parts |

|

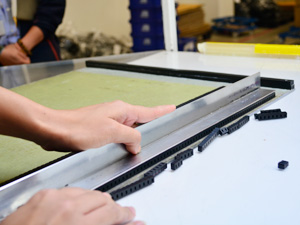

We supply not only compression molding parts, but also Post curing and precision cutting of rubber molding products processing. Some compression M/C are equipped with unique quartered molding system including 4 separate type mold for complex product shapes. 【Line of materials, feature】 *All of the substances above-mentioned within any All Material complies with RoHs Regulation. |

Products Sample |

|

Automotive parts *Rubber molding with Plastic insert

|

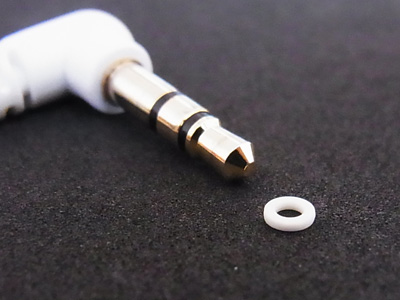

Connector parts

|

|

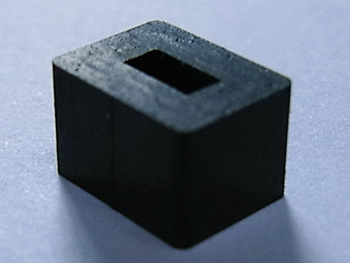

Camera parts

|

Automotive parts *Rubber molding

|

Production Equipment |

|

|

|

| |

|

|

|

| |

Chemically speaking, siloxane content remaining inside of silicone rubber may give rise to electric contact fault, thus, this oven can help to purge the substance from rubber component by long-time heating process.

Chemically speaking, siloxane content remaining inside of silicone rubber may give rise to electric contact fault, thus, this oven can help to purge the substance from rubber component by long-time heating process.