► CERTESS® is a problem-solving technology for issues like : |

|

① Wear The surface of molds are exposed to wear due to abrasive content (fiber glass, filler) and erosive wear due to repeated flow of plastic/rubber. Thanks to a high hardness and optimal friction properties, CERTESS® technologies increase the resistance to wear significantly, leading to lower maintenance, longer mold lifetime and higher productivity. |

② Oxidation resistance

|

③ Releasability & Flowability CERTESS® coatings prevents bonding between molds and plastic/rubber. This leads to a better flowability of the liquid plastic/rubber, and a better releasability once the injection cycle is over. This property is critical for plastic/rubber parts with thin sections and allows for more complex shapes. The full injection cycle time may also be reduced. |

► Three main advantages of PVD coating / CERTESS® |

CERTESS® is a plasma-enhanced sputtering coating process developed by HEF Group. Its main advantages are:

① Low temperature process

The sputtering technology allows for low temperature coating deposition, less than 180℃. As a consequence, any steel (SUJ, SCM, SKS) or aluminum alloy may be coated without any deterioration of the substrate’s mechanical properties or dimensions.

② High accuracy coating

CERTESS® coating technology allows for high uniformity and repeatability, which is critical for high accuracy industries such as semi-conductor industry or mold manufacturing. In addition, the low thickness of the coatings minimize the impact on the dimensions.

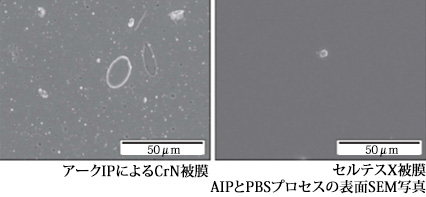

③ No droplet and smooth surface

③ No droplet and smooth surface

CERTESS® technologies was developed to minimize the occurrence of droplets like AIP (Arc Ion Plating). The coating surface is uniform and smooth in case of low roughness substrate.

► CERTESS® application examples on molds |

|

Industry |

Item |

Mold Material |

Molding material |

Example Solution |

Comparison |

Effect |

|

Connector |

Core pins |

Any steel may be coated |

LCP with 50% glass fiber |

CERTESS® X |

No treatment |

Extending the service life 2-3times |

|

Interior parts of automotive |

Cavity |

ABS-PC |

CERTESS® X |

No treatment |

Reducing the maintenance |

|

|

Plastic parts |

Cavity |

PS |

CERTESS® DLC |

No treatment |

Perfect filling, reducing cycle time by 30% |

|

|

Optical lens |

Mold |

Resin for optical |

CERTESS® N |

No treatment |

Reducing mold dirt |

|

|

LED lens |

Core |

Silicone rubber |

CERTESS® NS |

Hydrophobic surface treatment |

Extending the service life 2times |

|

|

Rubber for automotive |

Mold |

One-piece molding (Metal & Resin) |

CERTESS® X,XC |

No treatment |

Realizing automatic operation by a good release property. |

|

Rubber mold |

PE mold |

PS mold |

(Japanese / English) Gwenael BOLLORE

|

Mold & Dies are subjected to high temperature and repeated surface friction, which are conditions that facilitate surface oxidation and fretting corrosion. CERTESS® coatings prevents this occurrence up to 500℃and protects from corrosion by Halogen gas such as Cl.

Mold & Dies are subjected to high temperature and repeated surface friction, which are conditions that facilitate surface oxidation and fretting corrosion. CERTESS® coatings prevents this occurrence up to 500℃and protects from corrosion by Halogen gas such as Cl.