|

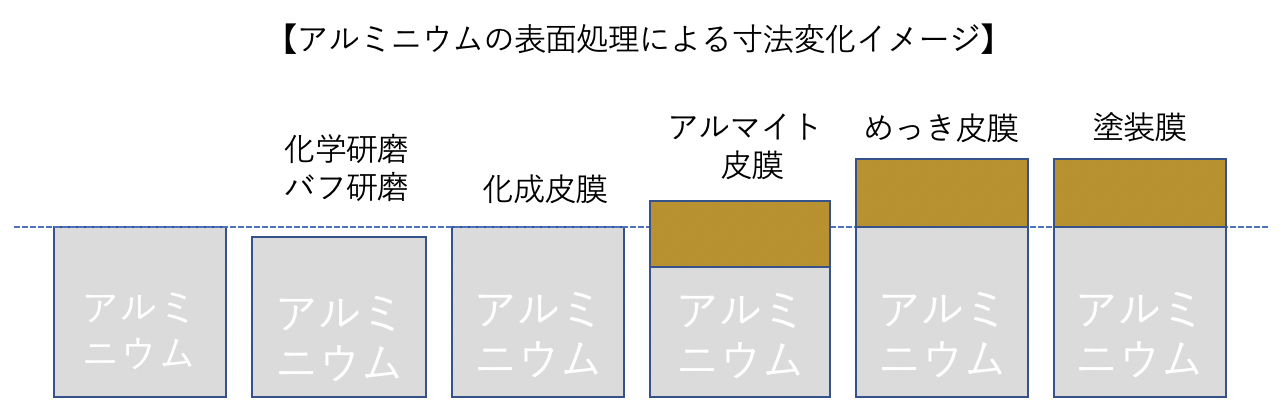

for Aluminum THAI SILVEC provides various surface treatments for Aluminum, including alumite, chemical conversion treatment and plating, all which have different characteristics. Pre-treatment (chemical polishing, satin finish, and buffing) is offered as a base treatment. We have the knowledge for proper surface treatments for each alloy of aluminum die casting. Improper surface treatments can cause problems if not done correctly. THAI SILVEC can perform surface treatment such as plating, anodizing, and chemical conversion on aluminum die-cast materials. We also consult and propose appropriate surface treatments that best fit the needs for each product. |

|

■Surface Treatments(Aluminum)■ (Click on picture for details )

|

Type |

Method |

Characteristics |

|

ALUMITE  |

Using aluminum as an anode, an aluminum oxide is formed by electrolysis. | Given its high corrosion resistance, it increases aluminum surface hardness, and improves wear resistance. Color can also be added using coloring agents or dyeing. | Standard anodize, hard anodize, and color anodize are available. |

|

Forming a thin film with a thickness of about 1 μm on the surface of aluminum from a chemical reaction. |

Since the treatment is relatively simple, the surface treatment for corrosion resistance can be performed at a low cost. However, given that the film is thin, there is no wear resistance. To stabilize adhesion to coatings and further improves corrosion resistance. |

Available from prototype to mass production. |

|

|

Available from prototype to mass production. |

Able to layer multiple metals to add various characteristics to aluminum. |

Copper, nickel, chromium, electroless nickel, black nickel, tin plating can be produced with barrels or jigs. |

|

|

Painting / printing |

Paint is applied to the aluminum surface by spraying or brushing. |

Freely create patterns and colors by selecting paints and inks. |

Our suppliers are able to support the process. |